Which Of These Prevents Conduction From Occurring

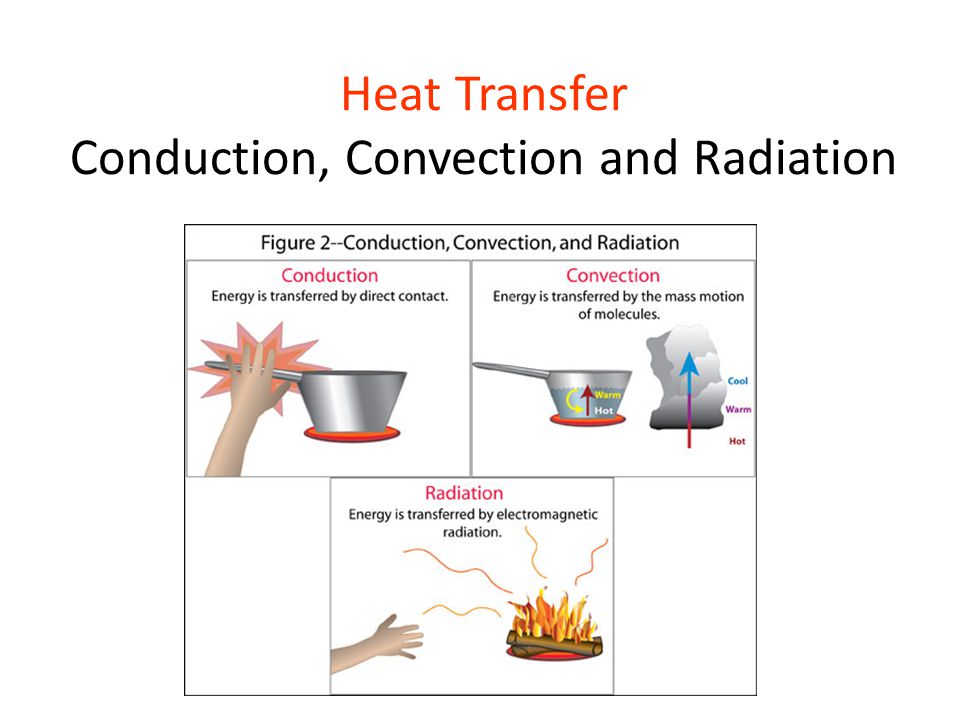

In a world increasingly reliant on efficient energy transfer, understanding the principles that govern heat flow is paramount. Conduction, one of the primary modes of heat transfer, plays a crucial role in everything from cooking to cooling electronic devices. Yet, just as important as knowing how heat travels is understanding what stops it in its tracks.

The quest to prevent conduction, and therefore thermal energy transfer, has spurred innovations across materials science and engineering. This has led to the development of sophisticated insulators, barrier technologies, and even metamaterials designed to manipulate heat flow at a fundamental level. The stakes are high, with implications for energy conservation, climate control, and the performance of advanced technologies.

This article delves into the various factors that can impede or prevent conduction. We examine the role of materials with low thermal conductivity, the effectiveness of vacuum barriers, and the impact of interface resistance, exploring the scientific principles that underpin each approach. We also consider the future directions in this critical field, where the ability to control heat flow promises to unlock new possibilities in diverse applications.

The Role of Materials in Preventing Conduction

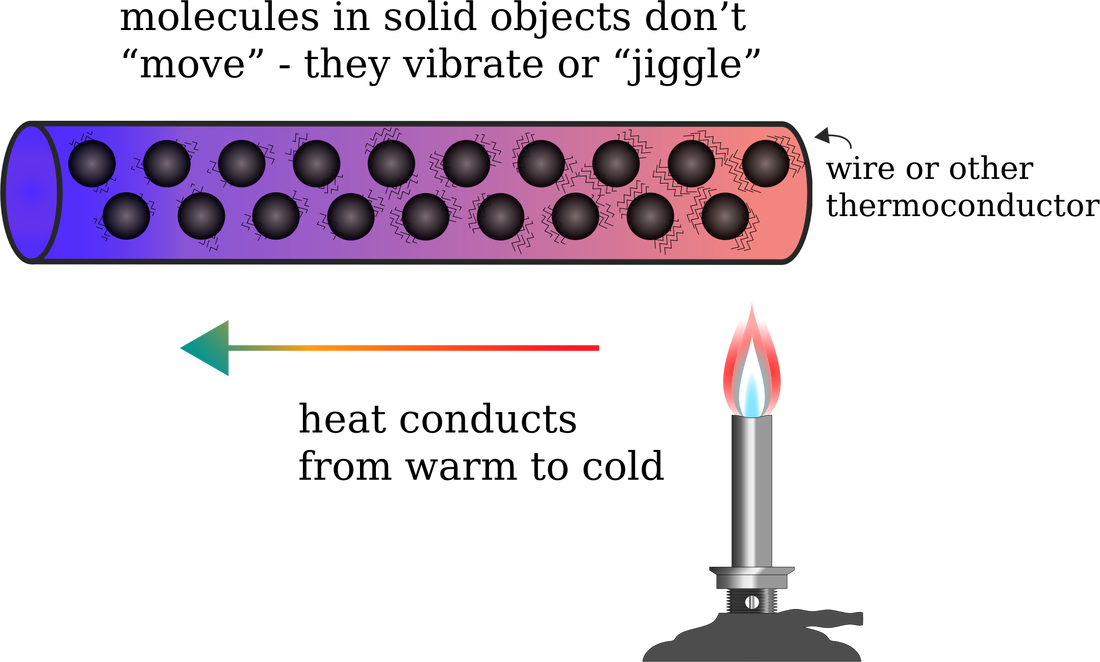

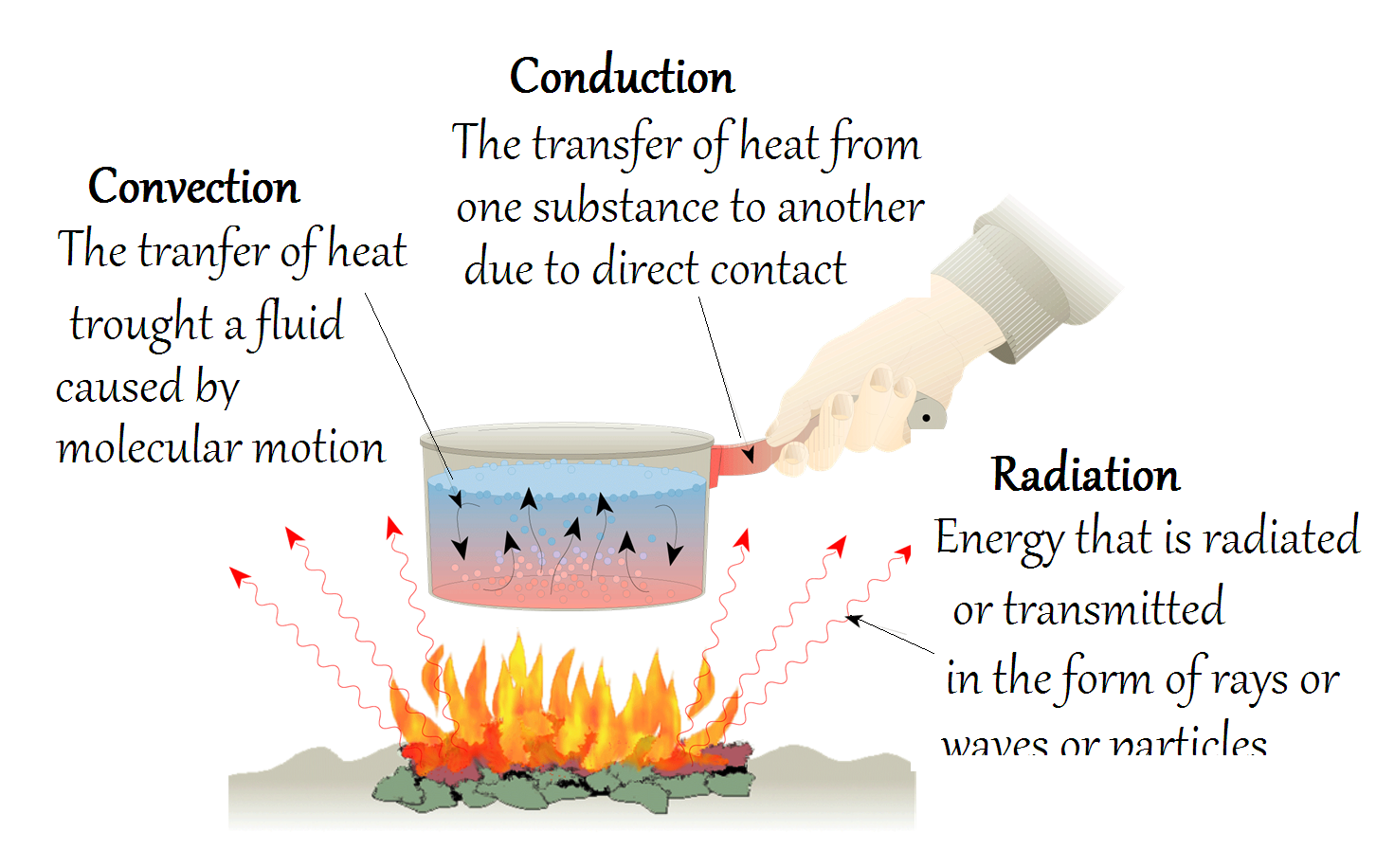

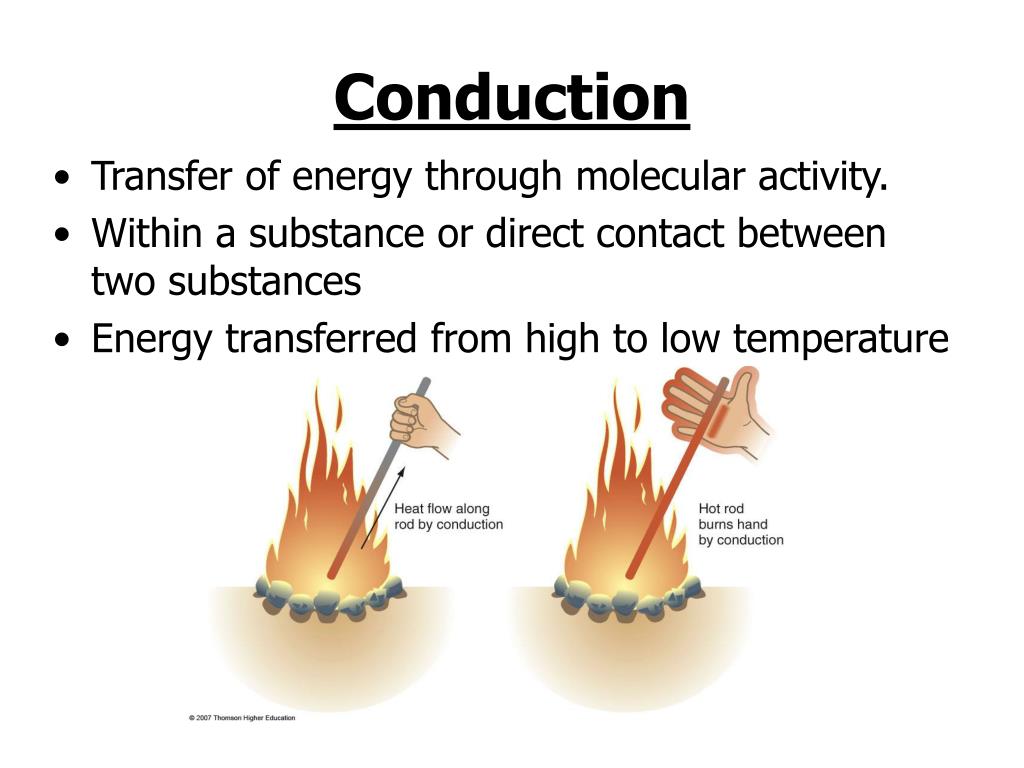

The most straightforward method of preventing conduction involves the use of materials with inherently low thermal conductivity. These materials, known as insulators, resist the flow of heat by hindering the movement of energy through their atomic structure.

Examples of such materials include fiberglass, mineral wool, polystyrene foam (Styrofoam), and aerogels. These substances possess a combination of characteristics that impede heat transfer, such as low density and a porous structure filled with air pockets.

Air itself is a poor conductor of heat. By trapping air within a material, conduction is significantly reduced, as heat struggles to navigate the gaps between the solid components. This is why a puffy jacket keeps you warm, trapping air and minimizing heat loss from your body.

Understanding Thermal Conductivity

Thermal conductivity is a material property that quantifies its ability to conduct heat. It is typically measured in Watts per meter-Kelvin (W/m·K). Lower values indicate better insulation properties. For example, copper has a high thermal conductivity (around 400 W/m·K), making it an excellent conductor, while polystyrene foam has a very low thermal conductivity (around 0.03 W/m·K), making it an effective insulator.

The effectiveness of a material as a thermal insulator depends not only on its thermal conductivity but also on its thickness. A thicker layer of insulation will provide greater resistance to heat flow than a thinner layer of the same material. This is a crucial consideration in building design and other applications where effective insulation is required.

Interestingly, even seemingly solid materials can exhibit varying degrees of thermal conductivity depending on their composition and structure. Nanomaterials, for instance, can be engineered with specific thermal properties to either enhance or suppress heat conduction, opening up possibilities for advanced thermal management solutions.

The Power of Vacuum Barriers

Another highly effective method for preventing conduction is creating a vacuum. Since conduction requires a medium (solid, liquid, or gas) to transmit heat, removing that medium eliminates the pathway for heat transfer.

This principle is utilized in thermos flasks (vacuum flasks or Dewar flasks) and cryogenic storage containers. These containers have a double-walled construction with a vacuum space between the inner and outer walls.

The vacuum minimizes heat transfer by conduction and convection (another mode of heat transfer involving the movement of fluids). Silvering the inner surfaces further reduces heat transfer by radiation, completing the trifecta of insulation strategies.

Limitations of Vacuum Barriers

While vacuum barriers are highly effective, they are not perfect. Some heat transfer can still occur through the supports holding the inner and outer walls together. These supports provide a conduction pathway, albeit a small one.

Maintaining a perfect vacuum over extended periods can also be challenging. Gases can slowly leak into the vacuum space, degrading its insulating performance over time. Therefore, vacuum systems often incorporate pumps or getter materials to maintain a high level of vacuum.

Despite these limitations, vacuum insulation is still a powerful technique for preventing conduction, particularly in applications where minimizing heat loss or gain is critical, such as in scientific instruments and space exploration.

Interface Resistance: A Critical Factor

Even when using insulating materials, the interfaces between different materials can play a significant role in hindering heat transfer. This phenomenon is known as thermal interface resistance or Kapitza resistance.

Interface resistance arises due to imperfections at the interface, such as microscopic gaps, surface roughness, and mismatched acoustic properties between the materials. These imperfections impede the flow of phonons, which are the primary carriers of heat in solids.

Reducing interface resistance is crucial for improving the overall thermal performance of systems. Techniques for minimizing interface resistance include using thermal interface materials (TIMs) such as thermal pastes, pads, and greases. These materials fill the microscopic gaps at the interface, providing a better pathway for heat conduction.

The Impact of Surface Properties

The surface properties of the materials in contact also influence interface resistance. Smoother surfaces with closer contact will generally exhibit lower interface resistance than rougher surfaces with more air gaps.

Surface treatments, such as polishing or coating, can be used to improve the surface properties and reduce interface resistance. In some cases, applying pressure to the interface can also improve thermal contact and reduce resistance.

Understanding and managing interface resistance is particularly important in electronic devices, where efficient heat dissipation is essential for preventing overheating and ensuring reliable performance. Poor thermal management can lead to reduced performance, premature failure, and even catastrophic damage.

Looking Ahead: Future Directions in Preventing Conduction

The field of thermal management is constantly evolving, with ongoing research focused on developing new materials and techniques for preventing conduction. Metamaterials are one area of particular interest.

Metamaterials are artificially engineered materials with properties not found in nature. Some metamaterials can be designed to manipulate heat flow in unusual ways, such as creating thermal cloaks that make objects invisible to heat or directing heat around sensitive components.

Another promising area of research is the development of advanced insulation materials with even lower thermal conductivity than existing options. Aerogels, for example, are being further refined to achieve even greater levels of insulation performance.

Furthermore, the integration of nanotechnology is opening up new possibilities for controlling heat flow at the nanoscale. By manipulating the structure of materials at the atomic level, scientists can tailor their thermal properties with unprecedented precision.

As our understanding of heat transfer continues to grow, and as new materials and technologies emerge, the ability to prevent conduction will become increasingly sophisticated. This will have profound implications for a wide range of applications, from energy conservation and climate control to advanced electronics and aerospace engineering.

Ultimately, the quest to control heat flow is driven by the need for greater efficiency, sustainability, and performance. By understanding the principles that govern conduction and the various strategies for preventing it, we can unlock new possibilities for a more efficient and technologically advanced future.

.+Electrons+in+atoms+collide+with+each+other+inside+the+object+being+heated..jpg)