A Company With A High Ratio Of Fixed Costs:

The cavernous warehouse hummed with the quiet energy of dormant potential. Rows upon rows of sophisticated machinery, cloaked in protective covers, stood silent. Sunlight streamed through the high windows, illuminating dust motes dancing in the air, a stark reminder of the operation's current, diminished capacity.

This is the story of Apex Manufacturing, a company grappling with the complexities and challenges inherent in a business burdened by a high ratio of fixed costs. While Apex's innovative spirit and commitment to quality remain undiminished, their financial model requires a delicate balancing act to navigate the ebbs and flows of market demand.

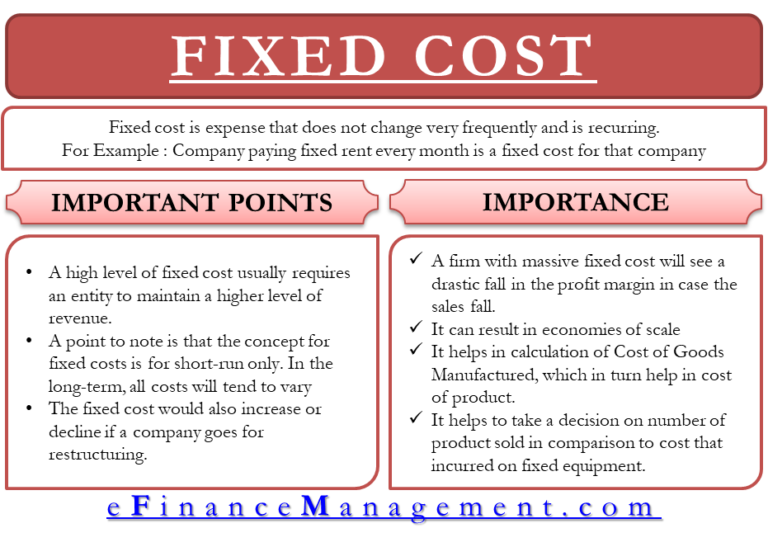

The Burden and the Promise of Fixed Costs

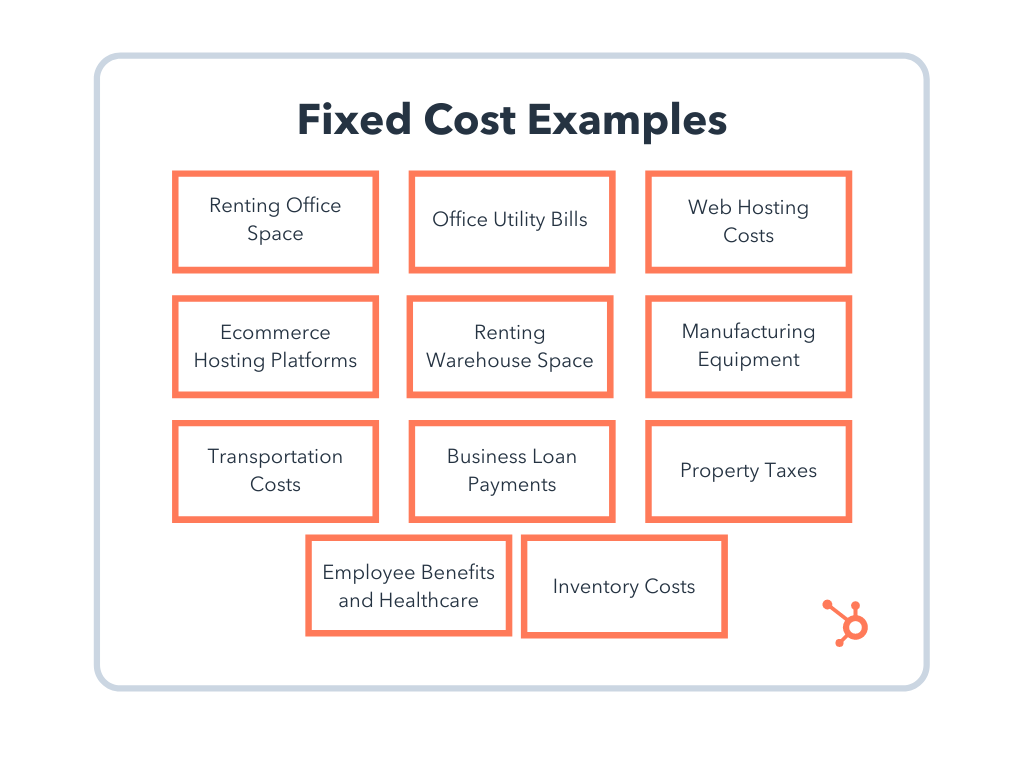

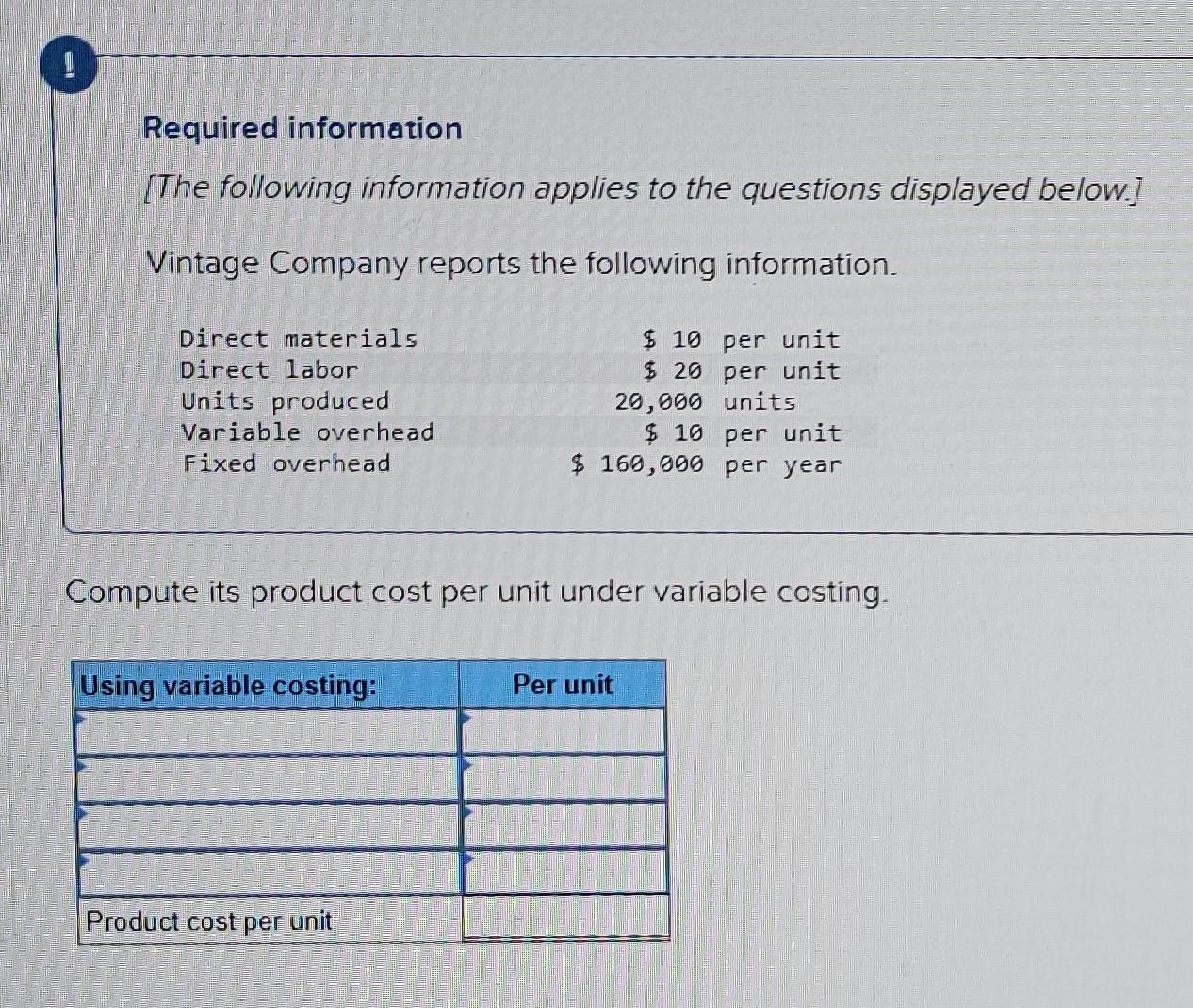

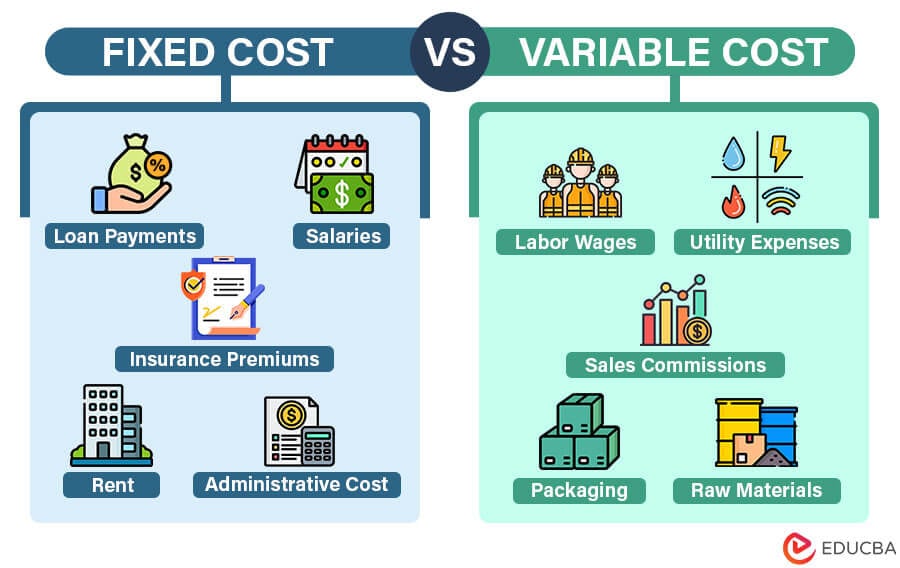

At its core, a high ratio of fixed costs means that a significant portion of Apex's expenses remain constant regardless of their production levels. Think of it as renting a large space – whether they produce one widget or a thousand, the rent is still due.

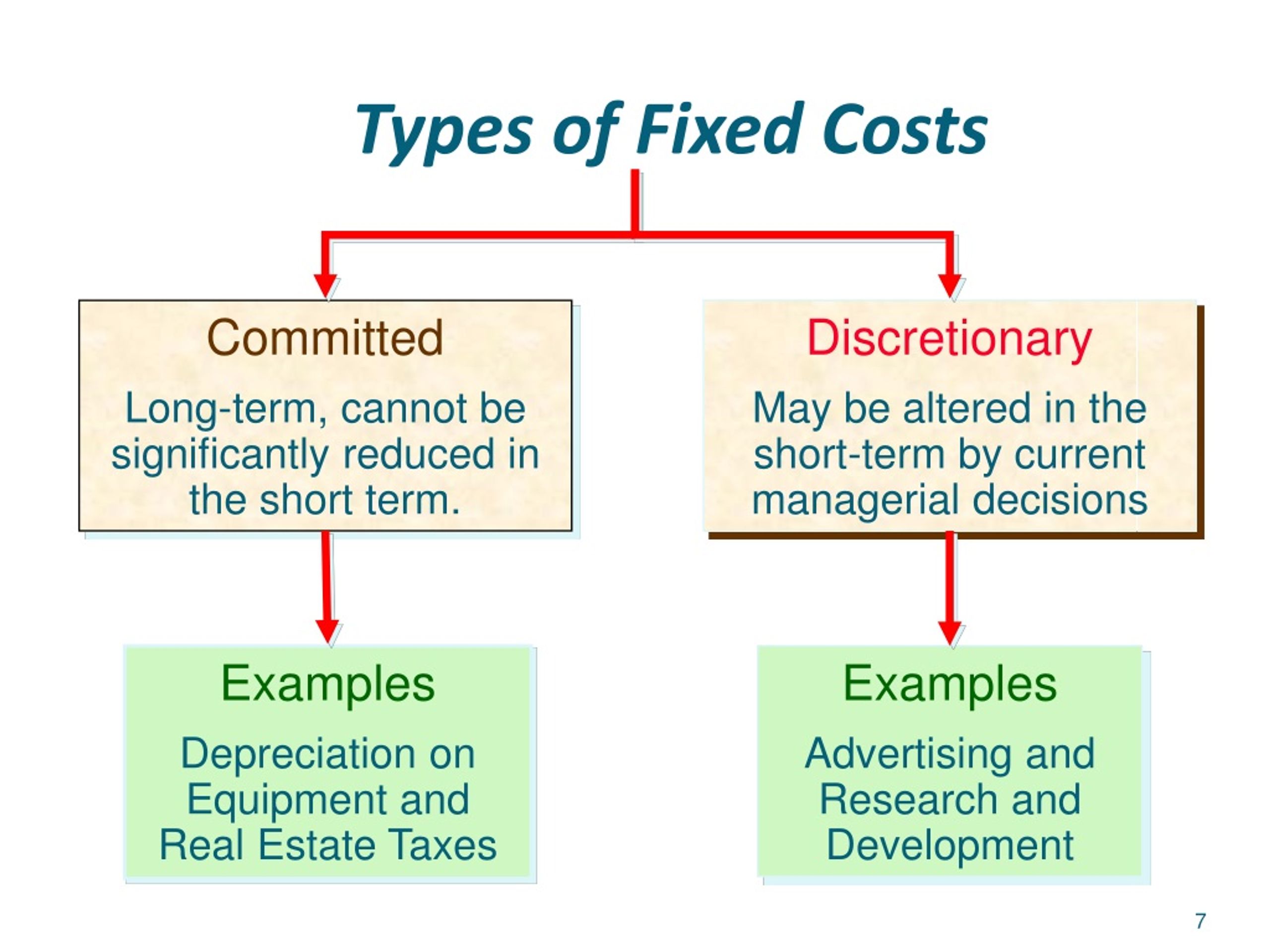

This includes expenses like depreciation on their expensive machinery, salaries for essential staff (engineers, maintenance crew), insurance premiums, and property taxes. These costs are largely unavoidable, representing a financial weight that can be especially challenging during periods of low demand or economic downturns.

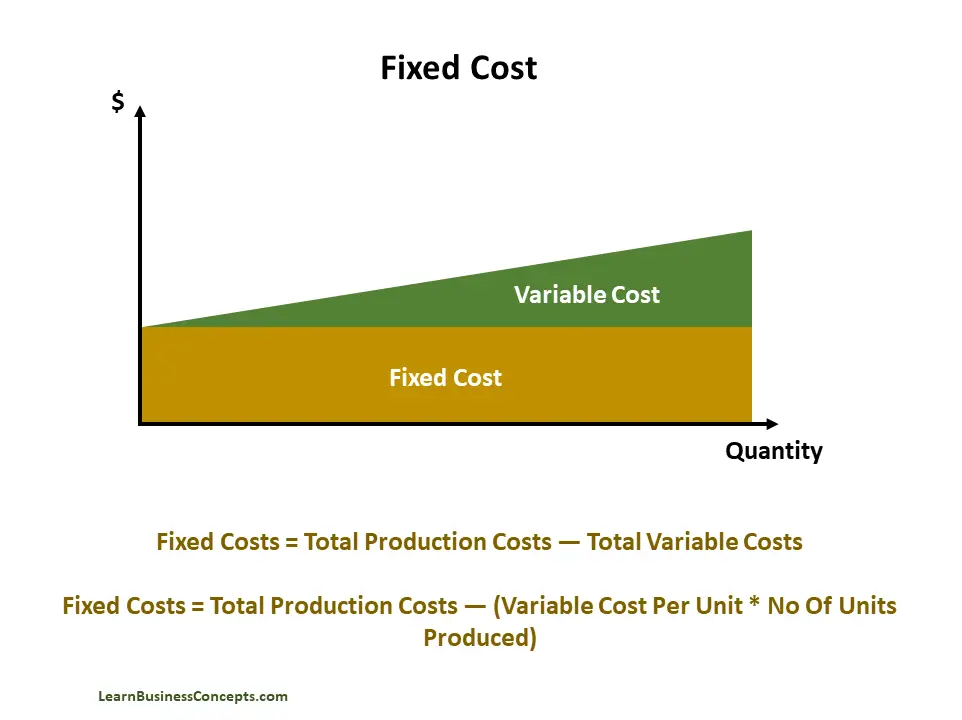

However, high fixed costs also contain the potential for significant profitability. When production volume is high, those fixed costs are spread across a larger number of units, leading to lower per-unit costs and increased profit margins.

Apex Manufacturing: A Deep Dive

Founded in 2010 by Elias Thorne, a visionary engineer with a passion for precision manufacturing, Apex quickly carved a niche for itself producing specialized components for the aerospace industry. Thorne's initial investment was substantial, focusing on acquiring state-of-the-art equipment capable of meeting the stringent demands of his target market.

This commitment to quality paid off. Apex secured several lucrative contracts with major aerospace firms, becoming known for its reliability and the superior performance of its components. Their reputation grew, solidifying their position as a trusted supplier.

However, the inherent volatility of the aerospace industry, coupled with unexpected economic headwinds, presented challenges to Apex's business model. Reduced demand from airlines and manufacturers in recent years led to a significant drop in production volume, exposing the vulnerability created by their high fixed costs.

Data from Apex's financial statements, reviewed by industry analysts, reveals that fixed costs account for approximately 70% of their total expenses. This figure is significantly higher than the industry average, placing Apex in a unique and precarious position.

Strategies for Survival and Success

Recognizing the urgent need to address the situation, Apex's management team, led by CEO Olivia Chen, implemented a series of strategic initiatives aimed at mitigating the impact of high fixed costs. Their approach involved a multi-pronged strategy focused on cost reduction, revenue diversification, and operational efficiency.

One key initiative involved negotiating more favorable terms with suppliers to reduce the cost of raw materials. This was achieved through bulk purchasing and forging stronger, long-term relationships with key vendors.

Another critical step was to explore new revenue streams. Apex began leveraging its expertise in precision manufacturing to target other industries, including automotive and medical device manufacturing. This diversification strategy aimed to reduce their reliance on the aerospace sector.

Perhaps the most significant undertaking was a comprehensive review of operational efficiency. This involved streamlining production processes, reducing waste, and implementing lean manufacturing principles. According to Chen, this initiative alone resulted in a 15% reduction in operating costs.

The Human Element

The challenges faced by Apex had a direct impact on its employees. While layoffs were avoided, employees were asked to embrace new roles and responsibilities, requiring a significant amount of flexibility and adaptability.

"It wasn't easy," admits Maria Rodriguez, a veteran machinist at Apex. "We all felt the pressure. But we also knew that we had to pull together to weather the storm. The company invested in retraining programs, which helped us learn new skills and contribute in different ways."

Rodriguez's sentiment reflects a broader sense of resilience and commitment within the company. The employees understood the challenges and were willing to work together to find solutions.

Looking Ahead: A Sustainable Future

Apex's journey underscores the importance of careful financial planning and risk management, particularly for companies with high fixed costs. While the initial investment in cutting-edge technology propelled Apex to success, the lack of diversification and inadequate contingency planning left them vulnerable to market fluctuations.

According to a recent report by the National Association of Manufacturers, companies with high fixed costs should prioritize building strong cash reserves and diversifying their customer base to mitigate potential risks.

As Apex navigates its path towards a more sustainable future, the lessons learned from this experience will undoubtedly shape their strategic decisions. The company is now more focused on building resilience into its business model, ensuring that it can withstand future economic shocks.

While the road ahead may not be easy, Apex's commitment to innovation, its skilled workforce, and its newfound focus on financial prudence provide a solid foundation for future success. The warehouse may still be quieter than it once was, but the spirit of innovation and determination remains strong, a beacon of hope for a brighter future.