All The Following Are Time Temperature Control For Safety Except

A critical food safety question has sparked widespread confusion and concern among food handlers and consumers: What doesn't qualify as a Time/Temperature Control for Safety (TCS) food? Misunderstanding the answer could lead to dangerous foodborne illnesses.

The core issue revolves around correctly identifying foods that require specific temperature and time controls to prevent the growth of harmful bacteria. Incorrectly classifying food can have severe public health consequences.

Understanding Time/Temperature Control for Safety (TCS) Foods

TCS foods, previously known as potentially hazardous foods (PHFs), are items that support the rapid growth of pathogenic microorganisms or the formation of toxins. These foods require careful temperature and time management to remain safe for consumption.

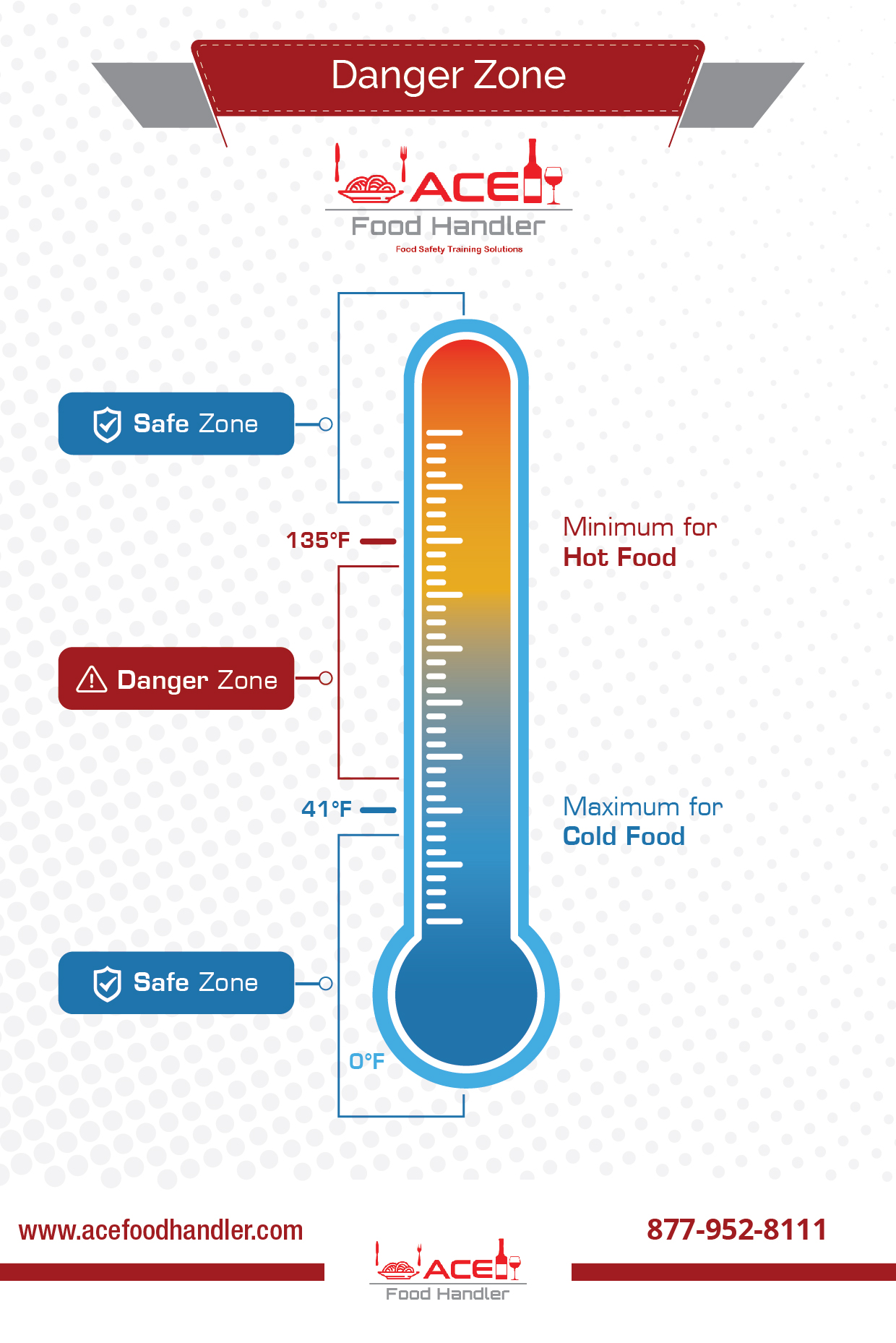

According to the FDA's Food Code, TCS foods generally have a water activity (aw) greater than 0.85 and a pH greater than 4.6. This environment is conducive to bacterial growth.

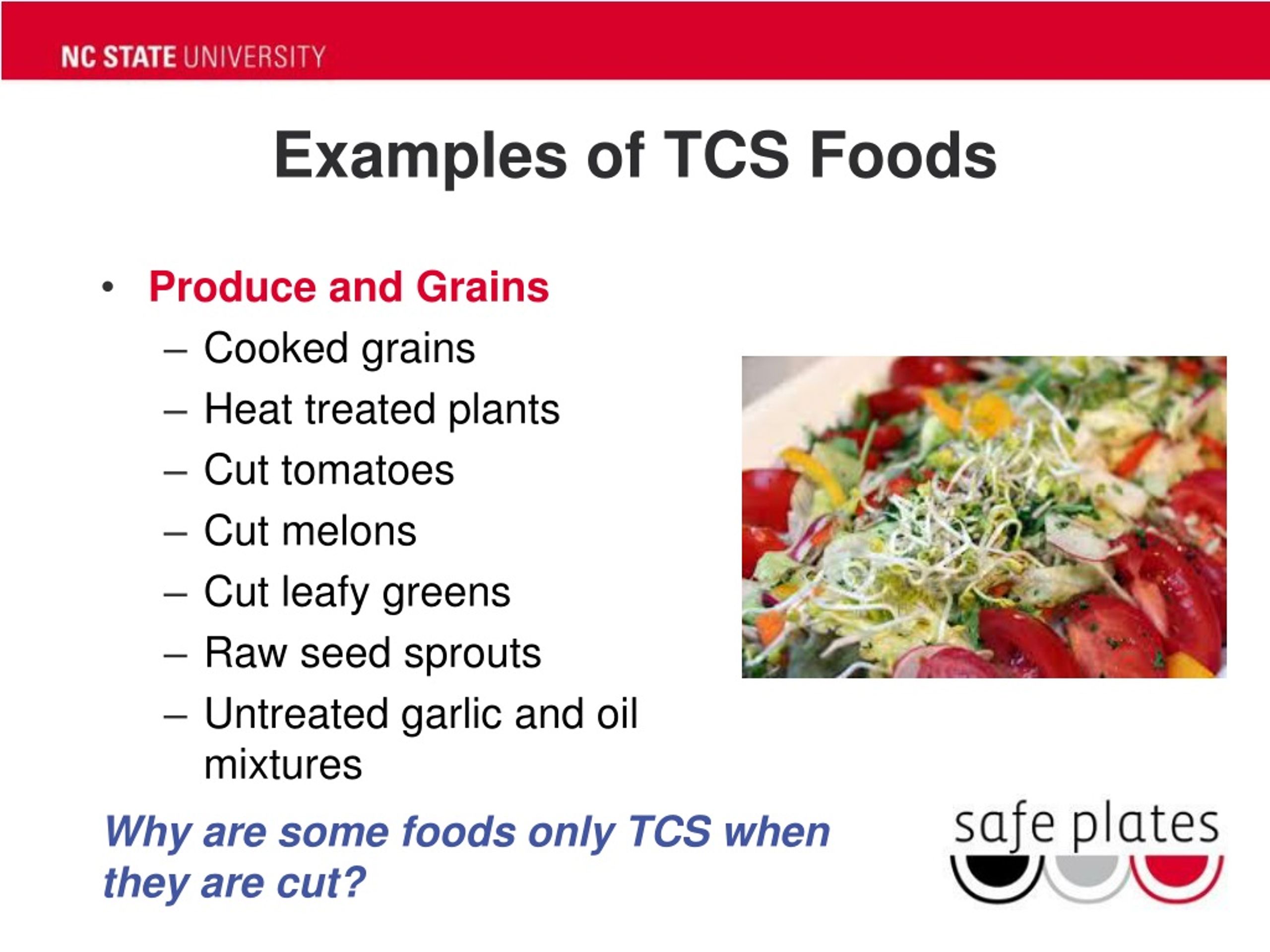

Common Examples of TCS Foods

Typical TCS foods include meat, poultry, fish, dairy products, eggs, and cooked vegetables. Cut leafy greens, melons, and tomatoes are also considered TCS foods.

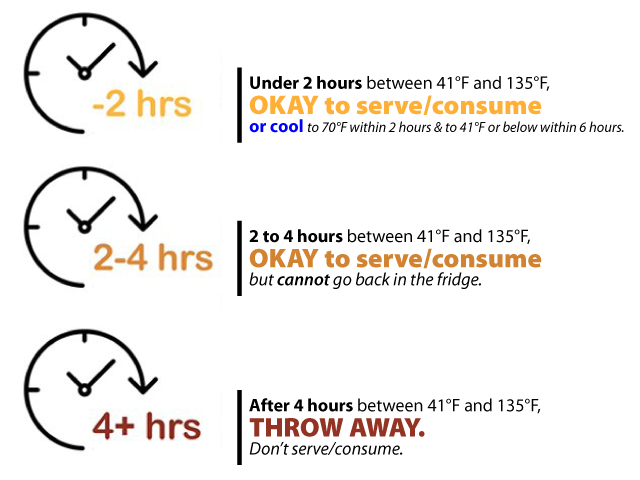

Improper handling of these foods at room temperature for extended periods can create a breeding ground for bacteria like Salmonella, E. coli, and Listeria.

The Exception: Identifying Non-TCS Foods

The critical question that has emerged: "All the following are Time Temperature Control for Safety EXCEPT?" This question highlights the importance of understanding what food items do NOT require rigorous temperature and time controls.

Foods with a low water activity (aw less than 0.85) or a high acidity (pH of 4.6 or lower) generally do not support rapid bacterial growth. These are classified as non-TCS foods.

Examples of non-TCS foods include dry goods like cereals, crackers, and flour. Products pickled in vinegar, like some vegetables, are also exempt from strict TCS requirements.

Why It Matters: Preventing Foodborne Illness

Misidentifying TCS and non-TCS foods can have dire consequences. Failing to refrigerate TCS foods can lead to bacterial proliferation and subsequent foodborne illnesses.

Conversely, applying unnecessary TCS protocols to non-TCS foods can increase operational costs and waste resources. Proper classification is crucial.

The Correct Answer: Unveiling the Exception

The correct answer to the question, "All the following are Time Temperature Control for Safety EXCEPT," will vary depending on the specific options provided in the question. However, the underlying principle remains the same.

The exception will always be a food item that inherently inhibits bacterial growth due to its composition or processing method. This may include items such as dry cereals or high-sugar syrups, which are not considered TCS foods.

“Understanding the science behind TCS foods and their exceptions is paramount to preventing foodborne outbreaks,” says Dr. Emily Carter, a food safety specialist at the National Restaurant Association.

Practical Implications for Food Handlers

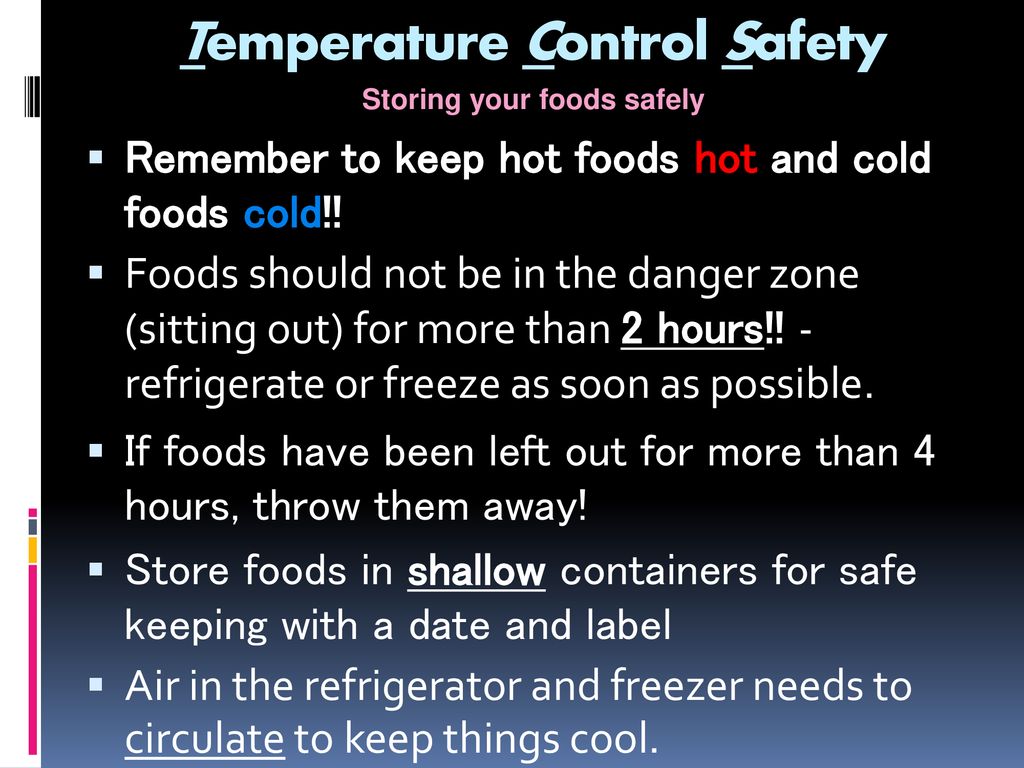

Food handlers must receive thorough training on TCS food identification and handling procedures. This training should cover the characteristics of TCS foods and the appropriate temperature and time controls.

Accurate temperature monitoring, proper cooling techniques, and adherence to established food safety protocols are essential. Regular audits and inspections should be conducted to ensure compliance.

Next Steps and Ongoing Developments

Food safety organizations are continually updating guidelines and resources on TCS foods. Staying informed about the latest recommendations is crucial for maintaining food safety standards.

The FDA is expected to release updated guidance on food labeling and risk assessment in the coming months. These updates will likely address the evolving understanding of TCS foods and their control measures.

Continued research and education are necessary to improve food safety practices and protect public health. The seemingly simple question reveals complexities that every food professional needs to understand.

+Food.jpg)

.jpg)