Bioethanol Yeast And Enzyme Strains For Sscf Commercially Available

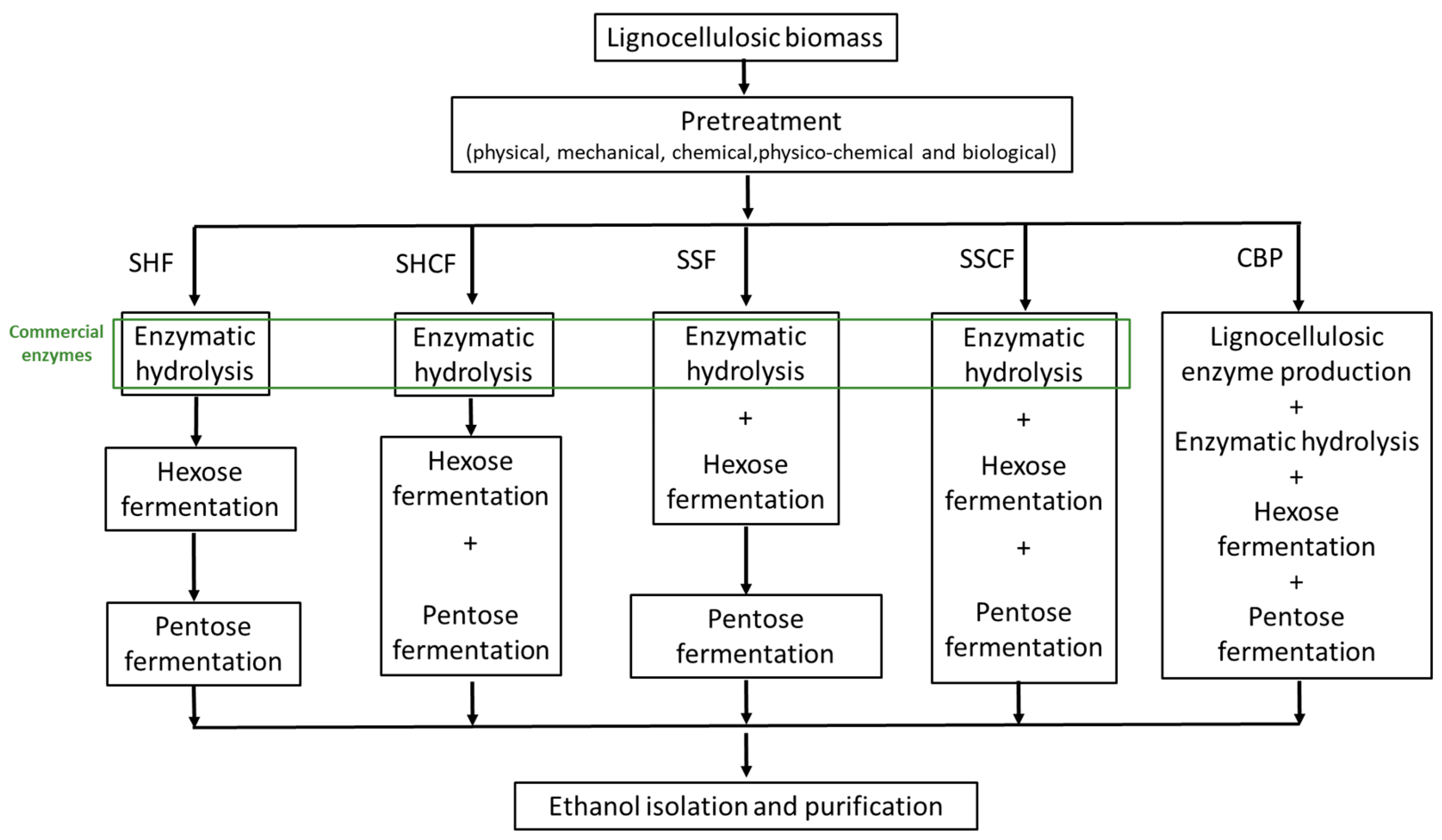

Game-changing bioethanol production is now within reach. Commercially viable bioethanol yeast and enzyme strains designed for Simultaneous Saccharification and Co-fermentation (SSCF) are immediately available, promising to reshape the biofuel landscape.

These optimized strains and enzyme cocktails offer enhanced efficiency and cost-effectiveness in converting biomass to ethanol, directly addressing key bottlenecks in the biofuel industry's scale-up efforts.

Availability Confirmed: A New Era for Biofuel Production

DSM, a global leader in life sciences, and Novozymes, a frontrunner in biotechnology, have separately announced the immediate availability of their advanced SSCF solutions. These products target a variety of feedstocks, including corn stover, wheat straw, and sugarcane bagasse.

DSM's Innovation: Yeast Strain MaxEthanol X5

DSM confirms that their MaxEthanol X5 yeast strain is commercially ready. This strain is engineered for high ethanol yield and tolerance to inhibitors commonly found in pretreated lignocellulosic biomass.

It offers robust performance at elevated temperatures, further reducing cooling costs and accelerating fermentation rates. MaxEthanol X5 is available now, directly from DSM or through authorized distributors.

Novozymes' Enzyme Cocktail: Cellic CTec3

Novozymes officially announced the commercial release of Cellic CTec3. This advanced enzyme cocktail is designed to efficiently break down cellulose and hemicellulose into fermentable sugars.

Cellic CTec3 boasts improved performance compared to previous generations, offering higher sugar yields and reduced enzyme loading. Immediate purchase options are available via Novozymes' online platform and sales representatives.

Key Benefits and Applications

These new bioethanol yeast and enzyme strains provide numerous advantages. Increased ethanol yields translate directly into higher profitability for biofuel producers.

Reduced enzyme loading and shorter fermentation times contribute to significant cost savings. The ability to process a wider range of feedstocks enhances the sustainability and flexibility of bioethanol production.

These advancements allow for the production of bioethanol from agricultural residues. This drastically reduces the dependency on fossil fuels and promotes a circular economy.

Who, What, Where, When, How

Who: DSM and Novozymes are the key players making these advancements available.

What: Commercially available bioethanol yeast (MaxEthanol X5) and enzyme strains (Cellic CTec3) optimized for SSCF.

Where: Available globally through DSM and Novozymes distribution networks.

When: Immediate availability, effective as of today's announcements.

How: Purchase directly from DSM and Novozymes or through authorized distributors. Technical support and application guidance are also provided.

Impact on the Biofuel Industry

The commercial availability of these advanced strains and enzymes represents a significant step forward. It directly tackles the economic and technical challenges hindering widespread bioethanol adoption.

Improved efficiency and cost-effectiveness make bioethanol a more competitive alternative to gasoline. This drives the transition to a more sustainable transportation sector.

These advancements also open doors for utilizing previously untapped biomass resources. Creating new revenue streams for farmers and rural communities is also now possible.

Next Steps and Ongoing Developments

DSM and Novozymes are actively working on further optimizing their bioethanol yeast and enzyme solutions. Expect continued improvements in yield, tolerance, and cost-effectiveness.

Collaborations with biofuel producers are underway. This will demonstrate the real-world performance and benefits of these technologies at commercial scale.

Further research and development are focused on expanding the range of usable feedstocks. This also includes exploring novel pretreatment methods to further enhance bioethanol production efficiency.

Bioethanol production is poised for dramatic change.