Cascade Side Shift Cylinder Rebuild

Urgent maintenance is underway after a critical failure sidelined operations. A vital Cascade side shift cylinder required immediate rebuild to prevent further delays.

This incident highlights the fragility of key components in material handling equipment. Rebuilding the cylinder is paramount to restoring operational efficiency and minimizing downtime.

Immediate Response to Cylinder Failure

The incident occurred at the Apex Distribution Center on October 26, 2023, halting operations in Warehouse Sector 4. The specific cylinder, a Model 55A-SDS, experienced a catastrophic seal failure during a routine pallet transfer.

This resulted in an immediate loss of hydraulic pressure and rendered the side shift mechanism inoperable. The affected forklift, a Yale ERP050VG, was taken out of service immediately.

Rebuild Process Underway

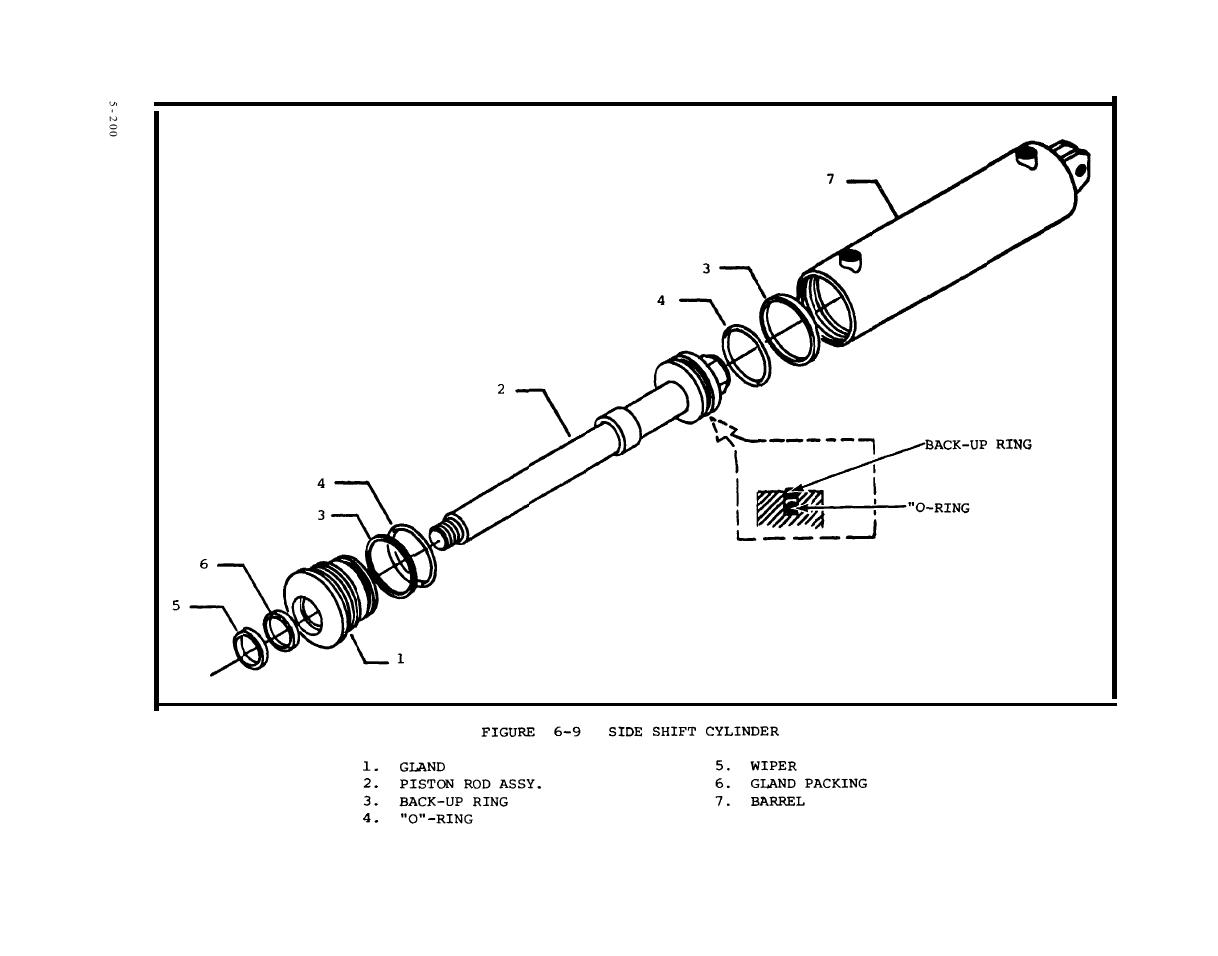

The cylinder rebuild is being conducted by Hydraulic Solutions Inc., a certified Cascade repair facility. Technicians are currently disassembling the cylinder to assess the full extent of the damage.

The rebuild process includes replacing all seals, inspecting the cylinder barrel for damage, and re-honing the cylinder if necessary. Damaged pistons and rods will also be replaced.

Hydraulic Solutions Inc. estimates the rebuild will take approximately 48 hours. A complete pressure test will be performed upon reassembly to ensure proper functionality and prevent future failures.

Impact on Operations and Mitigation Strategies

The shutdown of Warehouse Sector 4 is impacting order fulfillment timelines. Apex Distribution Center is experiencing a 15% reduction in throughput.

Management is implementing temporary measures to mitigate the impact. These include rerouting orders through unaffected sectors and deploying additional personnel to assist with manual handling.

Apex Distribution Center is also exploring the possibility of renting a temporary replacement forklift. This will allow them to maintain a higher level of operational capacity while the Yale ERP050VG is out of service.

Preventative Measures and Future Considerations

The failure underscores the importance of proactive maintenance. Apex Distribution Center is reviewing its preventative maintenance schedule for all material handling equipment.

This review will include more frequent inspections of hydraulic cylinders and seals. They are also considering implementing a predictive maintenance program that utilizes sensor data to identify potential failures before they occur.

Regular fluid analysis will also be incorporated into the schedule. This will help to identify contaminants and prevent premature wear of hydraulic components.

Cascade Corporation representatives are working with Apex Distribution Center to identify the root cause of the failure. They will also provide recommendations for optimizing the performance and lifespan of the side shift cylinders.

Next Steps and Ongoing Developments

Hydraulic Solutions Inc. is expediting the rebuild process. They anticipate completing the work by October 28, 2023.

Apex Distribution Center will conduct a thorough inspection of the rebuilt cylinder and the forklift before returning it to service. Operations are expected to return to normal within 24 hours of the forklift’s return.

Further updates will be provided as the rebuild progresses. Apex Distribution Center is committed to minimizing disruption and restoring full operational capacity as quickly as possible.