Cuanto Cuesta La Fibra De Carbono

Imagine yourself gliding along a sun-drenched coastline, the wind whispering secrets in your ear as your sleek, carbon fiber-framed bicycle effortlessly eats up the miles. Or picture a Formula 1 race, where every microsecond counts, and the lightweight, incredibly strong carbon fiber chassis provides the competitive edge. The allure of carbon fiber is undeniable – a material synonymous with high-performance, innovation, and a touch of the extraordinary.

But behind the sleek surfaces and impressive capabilities lies a crucial question: ¿Cuánto cuesta la fibra de carbono? (How much does carbon fiber cost?) This article delves into the intricacies of carbon fiber pricing, exploring the factors that influence its cost, its diverse applications, and the potential for future affordability.

Carbon fiber's journey from laboratory curiosity to mainstream application is a fascinating tale of innovation and perseverance. First developed in the late 1950s, early iterations were expensive and difficult to produce. The high cost limited its use to specialized applications like aerospace and defense.

The 1970s witnessed breakthroughs in manufacturing processes, leading to more cost-effective production methods. This opened the door for carbon fiber to enter the sports equipment market, finding its way into golf clubs, tennis rackets, and eventually, bicycles. These improvements were critical for making this material more accessible.

Several factors contribute to the final price tag of carbon fiber. The raw material, typically polyacrylonitrile (PAN), is a significant component. The cost of PAN itself fluctuates based on market demand and oil prices, as it is derived from petroleum. This fluctuation directly affects the end-user cost.

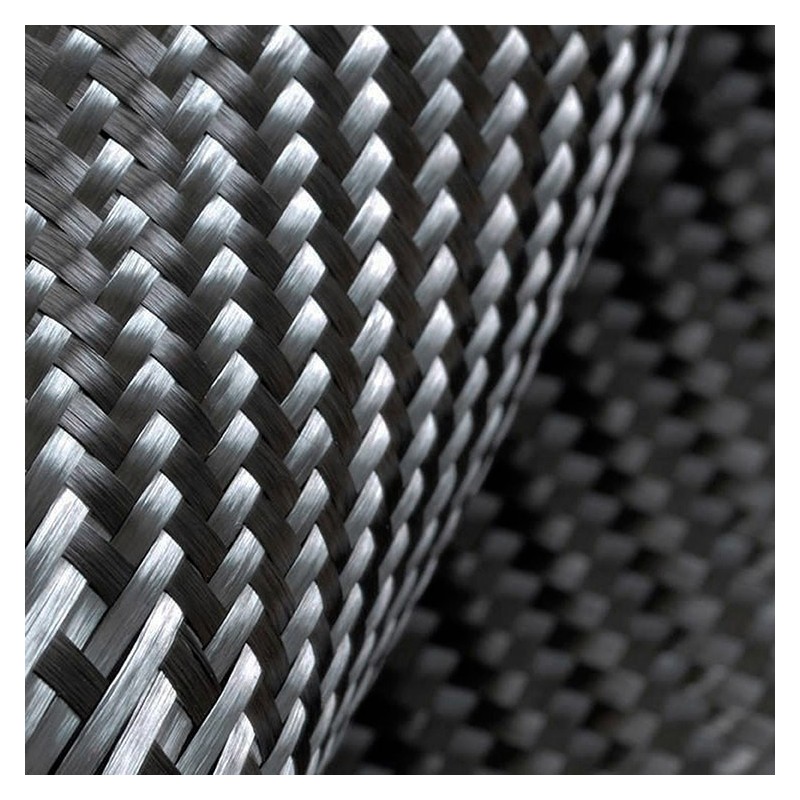

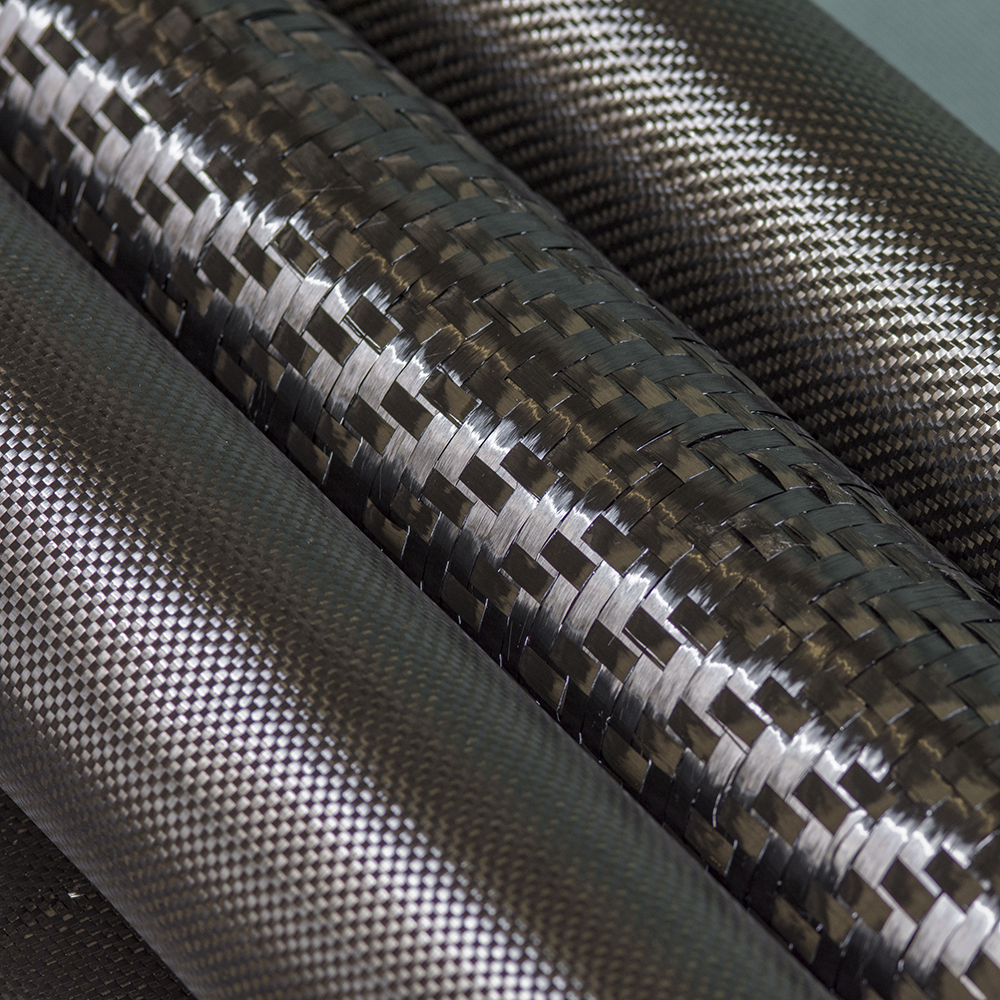

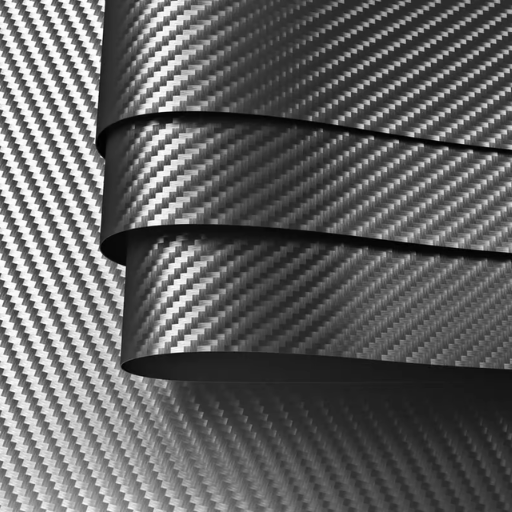

The manufacturing process is also complex and energy-intensive. It involves heating PAN fibers to extremely high temperatures in an oxygen-free environment, a process known as pyrolysis. This process carbonizes the fibers, aligning the carbon atoms to create the material's characteristic strength and stiffness.

Next, the fibers need to be processed into usable forms, such as woven fabrics or pre-impregnated sheets (prepreg). These intermediate products add further value and influence the overall cost. This is where the application determines the shape, form, and quantity of carbon fiber required.

Finally, labor costs, particularly in countries with stringent environmental regulations, contribute to the final price. These costs are incurred during the manufacturing and fabrication processes and are unavoidable.

The cost of carbon fiber isn't uniform. It varies significantly depending on the grade and quality. High-strength, aerospace-grade carbon fiber can command prices of $80-$120 per kilogram or even higher. Lower-grade, commercially available carbon fiber might range from $20-$40 per kilogram.

These prices are estimated and subject to change based on market conditions and quantity purchased. Purchasing in bulk can often lead to significant discounts.

Applications Across Industries

The unique properties of carbon fiber – its high strength-to-weight ratio, stiffness, and resistance to corrosion – have made it indispensable in various industries. Aerospace remains a major consumer, utilizing carbon fiber in aircraft wings, fuselages, and other structural components.

The automotive industry is increasingly adopting carbon fiber to reduce vehicle weight and improve fuel efficiency. Electric vehicles, in particular, benefit from carbon fiber's lightweighting capabilities, extending their range and improving performance. This shift towards electric vehicles is driving increased demand.

Sports equipment, from bicycles and golf clubs to skis and fishing rods, leverage carbon fiber for its performance-enhancing properties. The material allows for lighter, stronger, and more responsive equipment, giving athletes a competitive edge. Many sporting goods are now designed with carbon fiber as a standard.

Other applications include wind turbine blades, construction materials, and medical devices. The versatility of carbon fiber ensures its continued relevance across diverse sectors.

The Price-Performance Equation

While carbon fiber is undoubtedly more expensive than traditional materials like steel or aluminum, its superior performance often justifies the higher cost. The weight savings achieved with carbon fiber can lead to significant fuel efficiency gains in aerospace and automotive applications. This is a critical factor in the long term.

In sports equipment, the enhanced performance offered by carbon fiber can translate into faster times and improved results. The investment in carbon fiber can be seen as a strategic advantage.

Furthermore, carbon fiber's durability and resistance to corrosion can extend the lifespan of products, reducing long-term maintenance costs. This longevity often offsets the initial higher cost.

The Future of Carbon Fiber Pricing

The future of carbon fiber pricing hinges on several factors, including advancements in manufacturing technologies and increased demand. Researchers are actively exploring more efficient and cost-effective production methods. Reducing production costs is a primary goal.

The development of alternative precursors, such as lignin derived from wood, could also lower the cost of raw materials. Sustainable sourcing of raw material could be a long term game changer.

Increased recycling of carbon fiber is another promising avenue. Recovering and reusing carbon fibers from end-of-life products can reduce waste and lower the demand for virgin materials. As environmental awareness increases, recycling becomes even more important.

Greater adoption of automation in the manufacturing process can also reduce labor costs and improve production efficiency. Automated systems can ensure consistent quality at a lower cost.

"The key to unlocking the full potential of carbon fiber lies in making it more accessible and affordable," said Dr. Elena Rodriguez, a materials scientist at the National Institute of Standards and Technology. "Research and development efforts are focused on reducing production costs and exploring sustainable alternatives."

The increasing demand for carbon fiber in emerging applications, such as electric vehicles and renewable energy, is expected to drive further innovation and economies of scale. This increase in demand will naturally result in price optimization.

Ultimately, the cost of carbon fiber is likely to decrease over time as production technologies improve and demand increases. This will broaden its application across various industries and make its benefits more accessible to consumers.

¿Cuánto cuesta la fibra de carbono? The answer, as we've seen, is complex and multifaceted. It depends on the grade, the application, and the ever-evolving landscape of manufacturing and technology.

While the initial cost might seem daunting, the long-term benefits – improved performance, reduced weight, and enhanced durability – often outweigh the price. As innovation continues to drive down costs, carbon fiber is poised to play an even more prominent role in shaping the future of materials.

Think back to that bicycle ride along the coast, or that Formula 1 race. The allure of carbon fiber remains strong, promising a future where lightweight, high-performance materials are more accessible than ever before. The cost, though still a consideration, becomes less of a barrier as we embrace the possibilities this remarkable material offers.