Difference Between M20 And M25 Concrete

Concrete failures are costly and dangerous. Understanding concrete grades is critical for structural integrity and preventing disasters.

This article breaks down the vital differences between M20 and M25 concrete, focusing on their composition, strength, application, and cost, to inform immediate decision-making in construction projects.

Understanding Concrete Grades: M20 vs. M25

Concrete grades are designated by an "M" followed by a number, representing the characteristic compressive strength in N/mm² after 28 days of curing. M20 concrete has a characteristic compressive strength of 20 N/mm², while M25 concrete has a strength of 25 N/mm².

Key Composition Differences

Both M20 and M25 concrete use a mix of cement, sand, aggregate, and water. The primary difference lies in the proportion of these materials.

M25 concrete requires a higher cement content and a precisely controlled water-cement ratio to achieve its superior strength. This means a more meticulous mix design is essential for M25.

Strength and Durability

The most significant difference is compressive strength. M25 offers approximately 25% greater compressive strength than M20.

Durability also varies; M25 generally exhibits improved resistance to weathering, chemical attacks, and abrasion compared to M20. This makes it better suited for harsher environmental conditions.

Applications in Construction

M20 concrete is commonly used for less demanding structural elements like flooring, driveways, and simple foundations. It is suitable for residential buildings and light commercial construction.

M25 concrete is preferred for more robust structures, including columns, beams, slabs in high-rise buildings, and bridge decks. It's essential where higher load-bearing capacity and durability are paramount.

Cost Implications

M25 concrete is generally more expensive than M20. This is due to the higher cement content and the stringent quality control measures required during mixing and placement.

While M20 might seem cost-effective initially, using it inappropriately can lead to structural failures and higher long-term repair costs. Choosing the correct grade is about lifecycle costing, not just upfront savings.

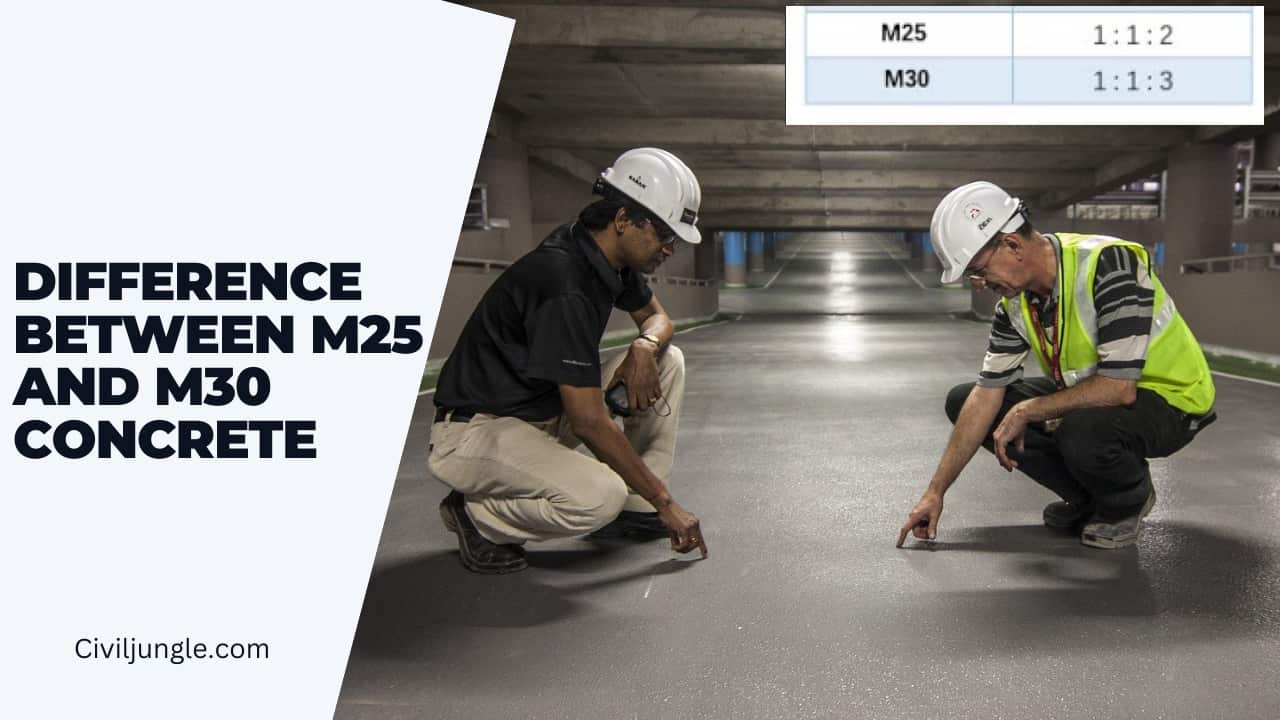

Mixing Ratios (Nominal)

While actual mix designs vary based on specific project requirements, nominal mixes offer a guideline. A typical nominal mix for M20 is 1:1.5:3 (Cement:Sand:Aggregate).

A common nominal mix for M25 is 1:1:2 (Cement:Sand:Aggregate). Remember, these are starting points and should be adjusted based on lab testing and expert advice.

Quality Control Imperative

Regardless of the grade, strict quality control is non-negotiable. This includes proper mixing, placement, compaction, and curing techniques.

Regular testing of concrete samples is crucial to ensure that the specified strength is achieved. Any deviation from the required strength can have severe consequences.

Next Steps and Ongoing Developments

Construction professionals must consult with structural engineers to determine the appropriate concrete grade for each project. Relying solely on nominal mixes is insufficient.

Continuous research and development are leading to innovative concrete mixes with enhanced strength and durability. Staying updated with these advancements is essential for best practices.

Ignoring these critical distinctions risks structural compromise. Prioritize accurate assessment and material selection to safeguard building integrity.