Design Features For Efficient Supply Chains Include

Supply chains face unprecedented pressures. Optimizing for efficiency is no longer optional; it's a survival imperative.

This article examines crucial design features needed to build resilient and efficient supply chains. Learn how companies are adapting to navigate disruptions and meet increasing demands.

Real-Time Visibility: The Cornerstone of Efficiency

Real-time visibility across the entire supply chain is critical. This requires implementing technologies like IoT sensors, blockchain, and advanced analytics platforms.

Companies like Amazon and Walmart have invested heavily in these systems. This allows them to track inventory, predict demand fluctuations, and proactively address potential bottlenecks.

A 2023 report by Gartner indicated that companies with real-time visibility experience a 15% reduction in supply chain costs. They also see a 20% improvement in order fulfillment rates.

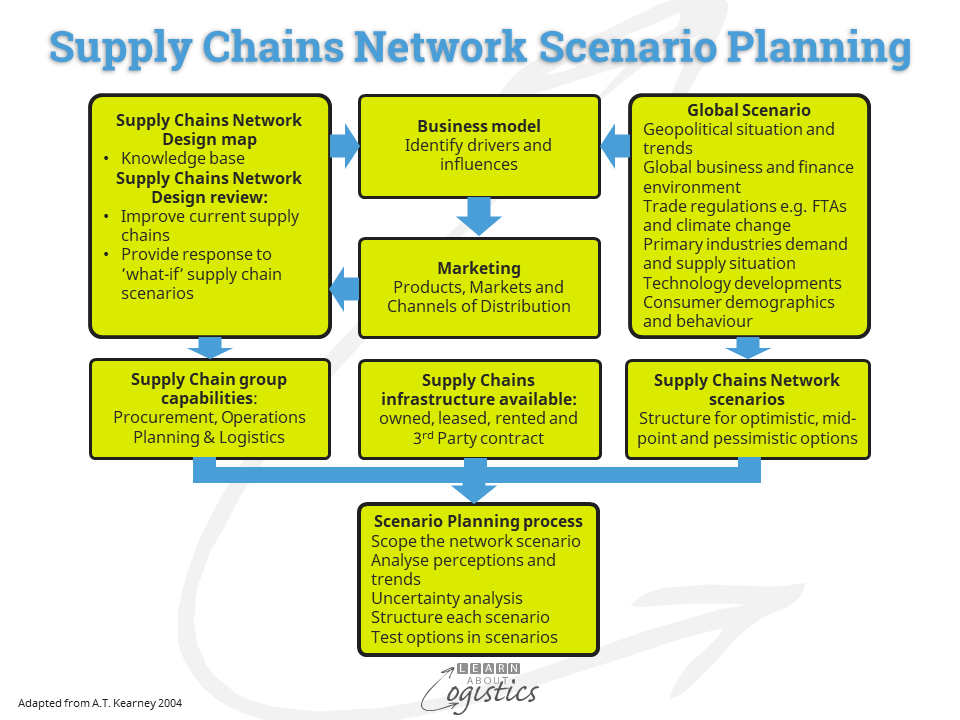

Agile Sourcing and Diversification: Mitigating Risk

Relying on single suppliers creates vulnerability. Agile sourcing and diversification are essential risk mitigation strategies.

Companies should establish relationships with multiple suppliers across different geographic regions. This ensures business continuity even when disruptions occur in specific areas.

Apple, for instance, utilizes a diverse network of suppliers across Asia, Europe, and the Americas. This strategy minimizes the impact of regional disruptions on their production.

Demand Forecasting and Predictive Analytics: Anticipating Needs

Accurate demand forecasting is fundamental to efficient inventory management. Leverage predictive analytics to anticipate future demand patterns.

Advanced algorithms can analyze historical data, market trends, and external factors to generate accurate forecasts. This allows companies to optimize inventory levels and reduce stockouts or excess inventory.

A recent study by McKinsey found that companies using advanced forecasting techniques improve forecast accuracy by up to 30%. This also reduce inventory holding costs by 10-15%.

Automated Processes and Robotics: Streamlining Operations

Automate repetitive tasks and leverage robotics to improve operational efficiency. Automation reduces errors, increases speed, and lowers labor costs.

Warehouses and distribution centers are increasingly adopting automated guided vehicles (AGVs), robotic picking systems, and automated packaging lines. These technologies can significantly enhance throughput and reduce turnaround times.

DHL, for example, has implemented robotic solutions in numerous facilities. This resulted in a 25% improvement in order processing speed and a 15% reduction in labor costs.

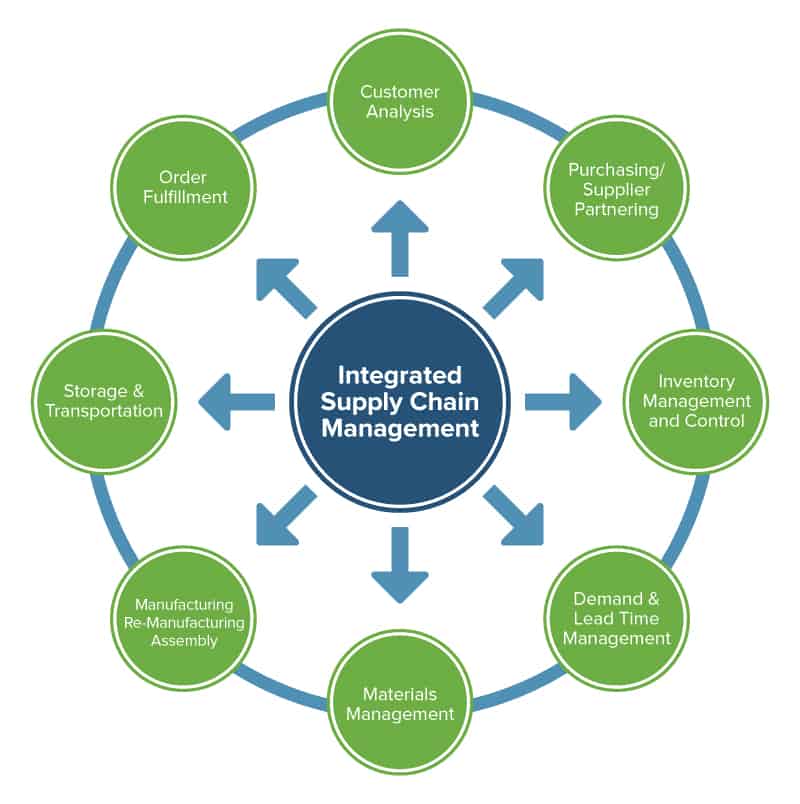

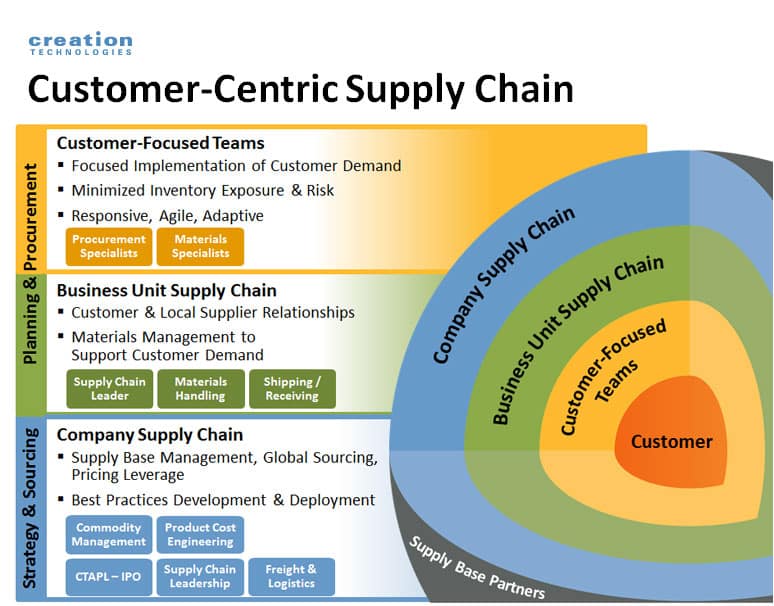

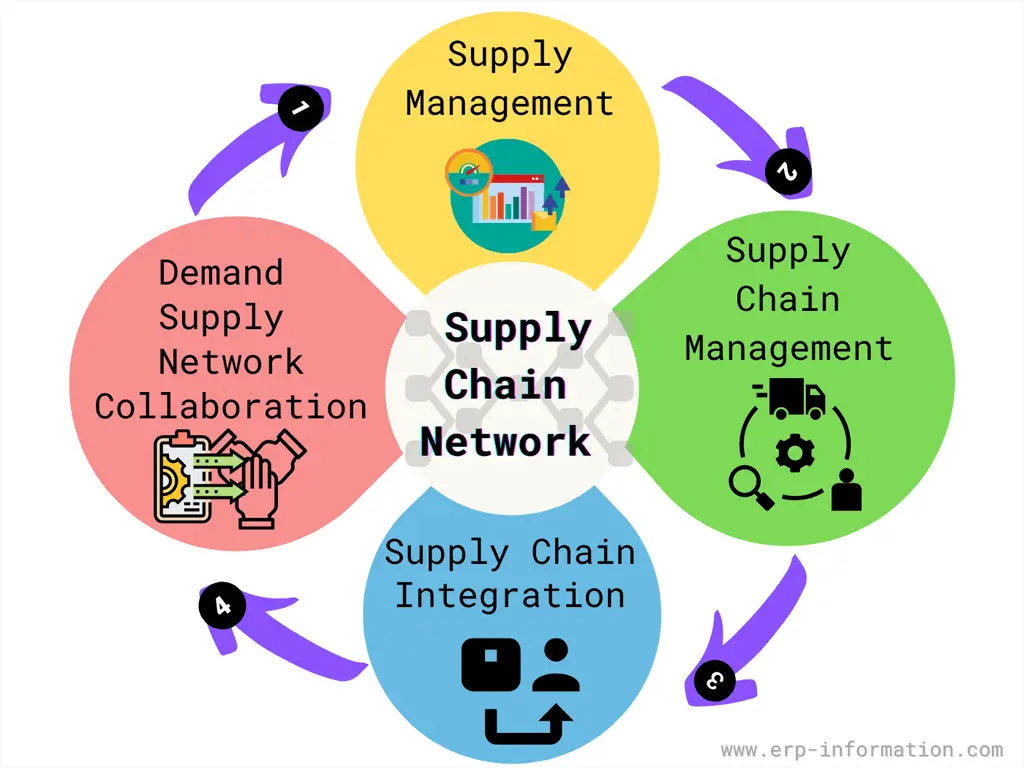

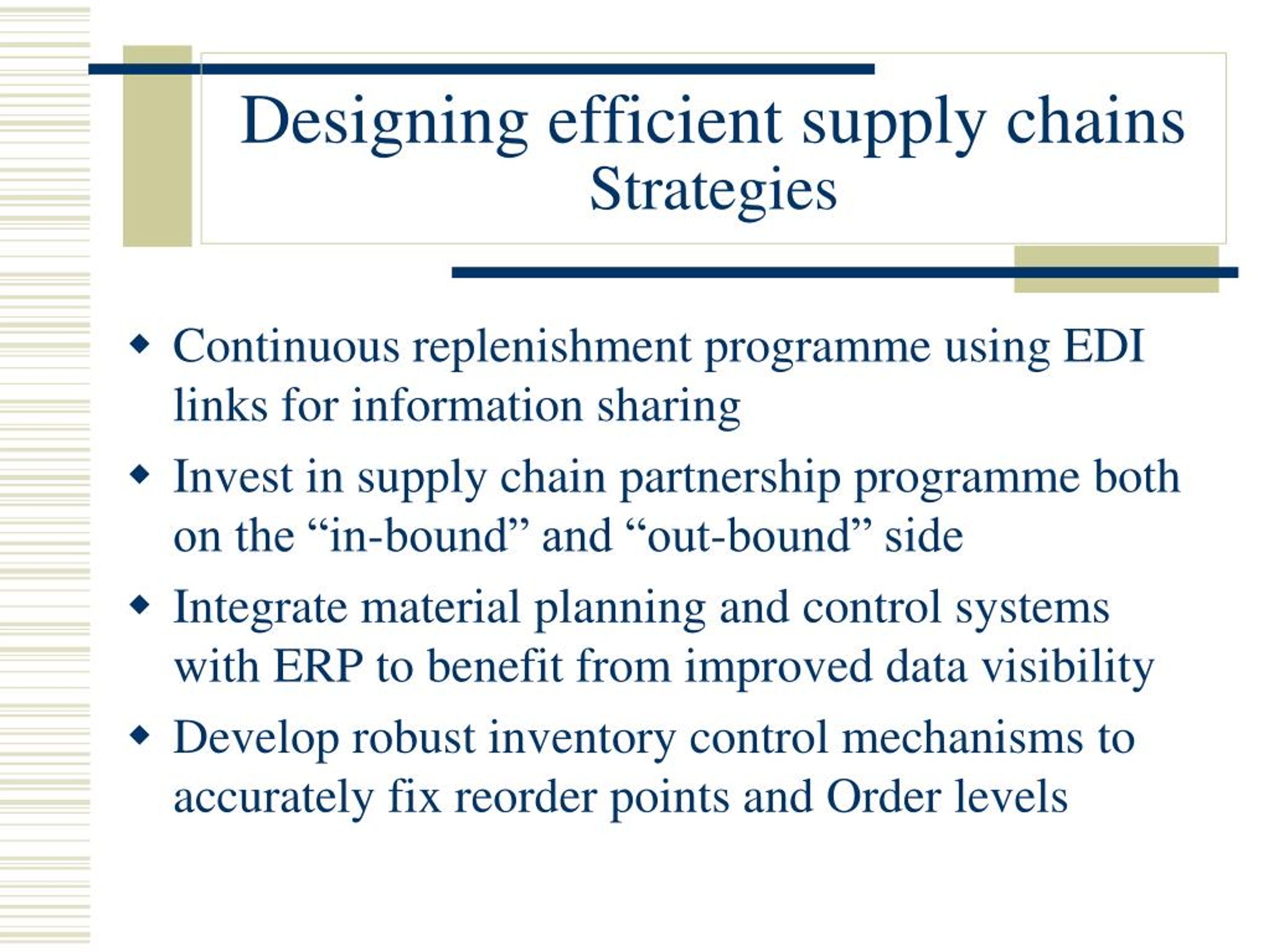

Collaboration and Information Sharing: Building Stronger Relationships

Foster collaboration and information sharing among all stakeholders in the supply chain. This includes suppliers, manufacturers, distributors, and customers.

Sharing data on demand forecasts, inventory levels, and production schedules enables better coordination and reduces the bullwhip effect. This, in turn, enhances responsiveness and improves overall efficiency.

Companies like Procter & Gamble and Unilever have implemented collaborative planning, forecasting, and replenishment (CPFR) programs. This led to significant improvements in supply chain performance.

Sustainable Practices: Ensuring Long-Term Viability

Integrate sustainable practices throughout the supply chain to ensure long-term viability. This includes reducing carbon emissions, minimizing waste, and promoting ethical sourcing.

Consumers are increasingly demanding environmentally friendly products and practices. Companies that prioritize sustainability gain a competitive advantage and build brand loyalty.

IKEA, for instance, has committed to using 100% renewable energy and sourcing all wood from sustainable forests. This demonstrates their commitment to environmental responsibility.

Investing in Supply Chain Talent: A Critical Success Factor

Invest in training and development programs to build a skilled supply chain workforce. This includes professionals with expertise in data analytics, logistics, and technology.

A knowledgeable and adaptable workforce is essential for navigating the complexities of modern supply chains. Companies must prioritize talent development to ensure they have the skills needed to drive innovation and improve efficiency.

According to the Association for Supply Chain Management (ASCM), there is a growing skills gap in the supply chain industry. This highlights the importance of investing in talent development initiatives.

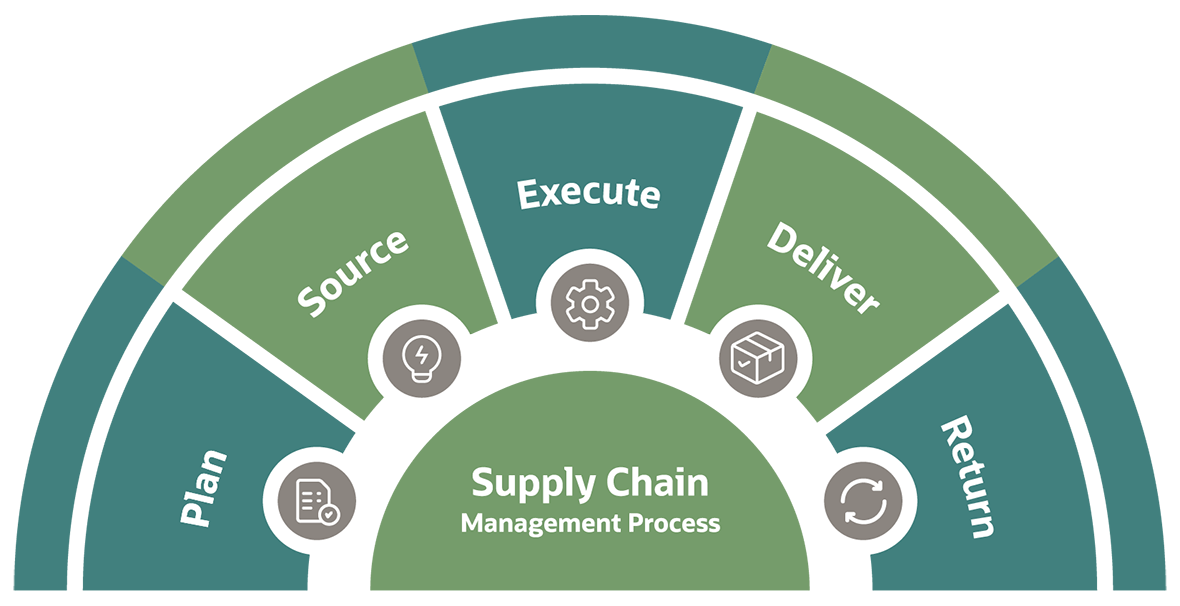

Moving Forward: Continuous Improvement

The journey toward an efficient supply chain is ongoing. Companies must continuously monitor performance, identify areas for improvement, and adapt to changing market conditions.

Regularly assess your supply chain's performance metrics, benchmark against industry best practices, and implement corrective actions as needed. Embracing a culture of continuous improvement is essential for maintaining a competitive edge.

Immediate action is critical for businesses to secure their supply chains. Prioritize investments in technology, talent, and collaborative relationships to build resilience and drive efficiency.