High Pressure Large Steam Boiler Modern Industrialization

Industrial sectors face a transformative shift as advanced high-pressure large steam boilers revolutionize energy production and efficiency. The deployment of these systems promises significant gains in operational output and reduced environmental impact.

These boilers represent a major leap in steam generation technology, designed to meet the escalating demands of modern industry while adhering to stringent environmental regulations. This article outlines the implementation, impacts, and future prospects of high-pressure large steam boilers in the industrial landscape.

Unveiling the High-Pressure Boiler Revolution

GE Power recently completed the installation of a new 900 MW supercritical boiler at the Brenner Energy Facility in Austria, marking a significant milestone in European energy infrastructure. This boiler operates at pressures exceeding 3,200 psi and temperatures reaching 1,112°F (600°C), significantly increasing efficiency.

The Brenner Energy Facility aims to cut CO2 emissions by 20% compared to previous generation units, demonstrating the tangible environmental benefits of this technology. This initiative addresses Europe's growing need for cleaner and more efficient energy solutions.

Key Players and Their Contributions

Siemens Energy has emerged as a leading force in high-pressure boiler technology, providing cutting-edge solutions to power plants worldwide. Their Benson boiler design, known for its adaptability and high performance, is featured in multiple installations globally.

Mitsubishi Heavy Industries (MHI) has also made significant contributions, with installations in Asia showing substantial improvements in power generation efficiency. These advancements highlight the global push towards optimizing energy use and reducing environmental footprints.

Benefits Across Industries

The chemical processing industry sees improvements through stable and high-quality steam supply, enhancing production consistency. Food and beverage manufacturers now benefit from improved sanitation control via advanced sterilization and process heating.

The enhanced heat recovery from high-pressure boilers reduces energy consumption, cutting operational costs and waste output. Textile manufacturing is another key sector benefiting from the improved efficiency of these boilers.

Environmental Impact and Sustainability

By design, high-pressure large steam boilers reduce greenhouse gas emissions, helping industries meet stringent environmental regulations. These boilers promote energy efficiency by using resources more effectively and minimizing waste.

Implementation of these boilers supports industries in their efforts to reduce carbon footprints and enhance their environmental stewardship. Many companies have reported significant reductions in their environmental impact following the adoption of this technology.

Technical Specifications and Innovation

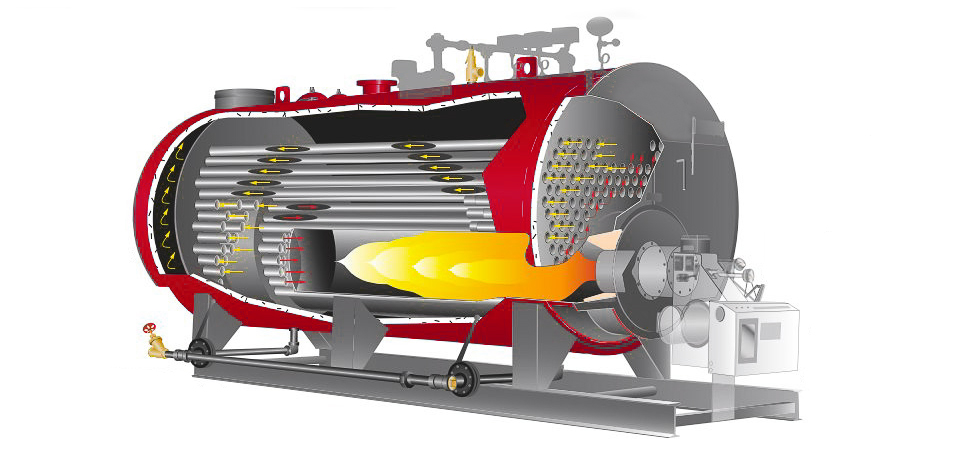

Advanced materials, such as creep-resistant steel alloys, play a crucial role in ensuring the longevity and performance of these boilers. Enhanced automation and control systems allow for real-time adjustments and optimized operation.

Sophisticated water treatment technologies prevent scale build-up and corrosion, extending the boiler's lifespan and efficiency. Innovations in burner designs help optimize combustion, reducing emissions and fuel consumption.

Challenges and Solutions

High upfront costs present a barrier to entry for many companies, requiring significant capital investment. The complexity of installation and maintenance demands specialized expertise, potentially causing delays and additional expenses.

Government incentives and tax breaks are being explored to mitigate the financial burden, encouraging broader adoption. Comprehensive training programs and partnerships with boiler manufacturers help address the skills gap.

Global Adoption and Future Trends

Emerging economies like India and China are rapidly adopting high-pressure boiler technologies to meet their increasing energy demands. North America and Europe are focusing on retrofitting existing power plants with high-efficiency boilers to improve sustainability.

The integration of artificial intelligence and machine learning promises to further optimize boiler performance and predictive maintenance capabilities. Research and development efforts are ongoing to explore the use of alternative fuels like biomass and hydrogen in high-pressure boilers.

The Role of Regulatory Bodies

Organizations such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) are setting stringent standards for boiler emissions. Compliance with these standards requires industries to invest in modern and efficient technologies like high-pressure boilers.

Governments worldwide are enacting policies to incentivize the adoption of clean energy technologies and penalize inefficient practices. These regulations create a favorable environment for the deployment of high-pressure large steam boilers.

Economic Implications

While the initial investment is substantial, long-term operational savings can be significant due to enhanced efficiency. Industries can expect reduced fuel consumption, lower maintenance costs, and improved productivity.

The adoption of high-pressure boilers can boost competitiveness by reducing operational expenses and increasing overall efficiency. This also results in a more sustainable and environmentally friendly production process.

Next Steps and Ongoing Developments

The industry is focusing on developing more compact and modular boiler designs to reduce installation time and space requirements. There is a growing emphasis on incorporating digital twins and advanced analytics to optimize boiler performance.

Continued investment in research and development is essential to further enhance the efficiency and sustainability of high-pressure large steam boilers. Stakeholders are encouraged to collaborate and share best practices to accelerate the adoption of this transformative technology.