In Terms Of Facility Design What Is Throughput

In the high-stakes world of facility design, a single metric can determine success or failure: throughput. From bustling hospitals to sprawling manufacturing plants, the ability to efficiently process materials, people, or information is paramount.

Insufficient throughput leads to bottlenecks, delays, and ultimately, lost revenue. Conversely, optimized throughput translates to increased productivity, reduced costs, and a competitive edge. But what exactly is throughput in the context of facility design, and how can it be maximized?

Understanding Throughput: The Nut Graf

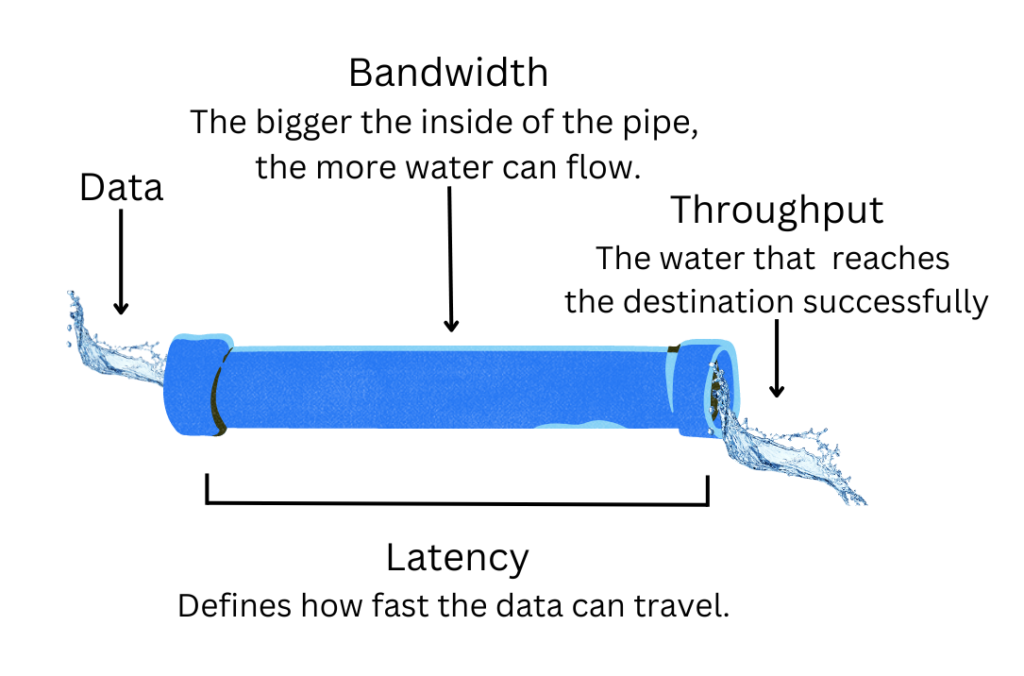

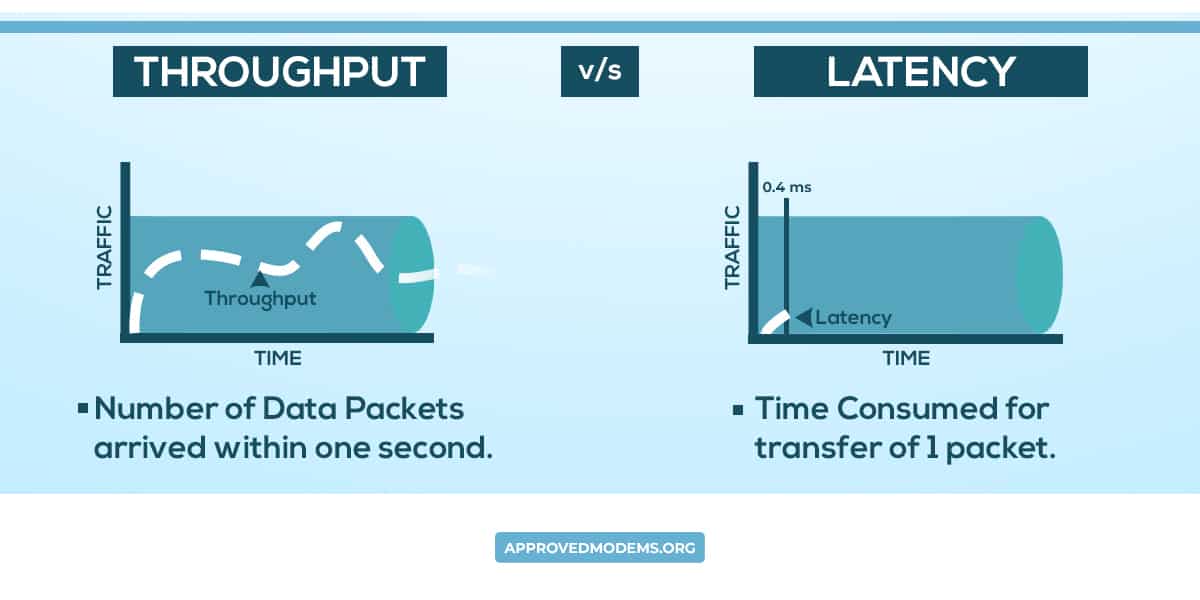

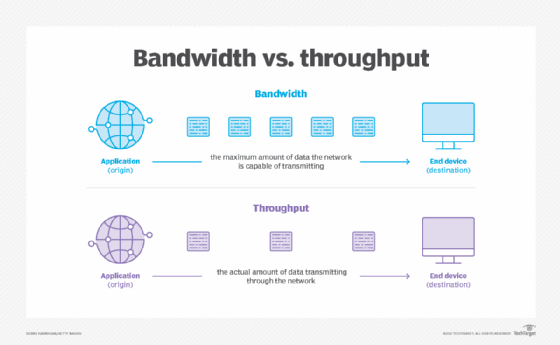

At its core, throughput refers to the rate at which a facility can process inputs and transform them into outputs over a given period. In facility design, this concept encompasses not only the raw number of items produced but also the speed and efficiency with which people, materials, and information flow through the space.

It's a critical measure of operational effectiveness, directly impacting profitability, customer satisfaction, and overall business performance. A well-designed facility, therefore, prioritizes throughput by minimizing friction, streamlining processes, and optimizing the use of space and resources.

Key Factors Influencing Throughput

Numerous design elements contribute to a facility's throughput capacity. These factors can be broadly categorized into layout, technology, process design, and human factors. Let's examine each in detail.

Layout Optimization

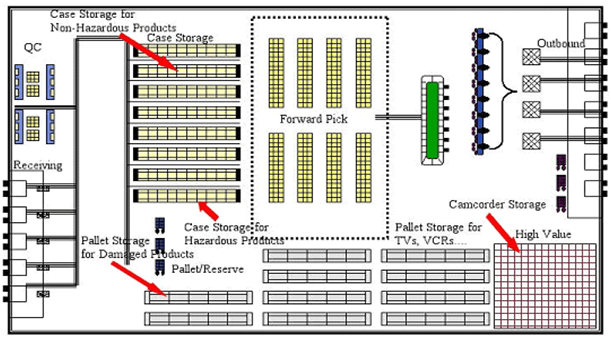

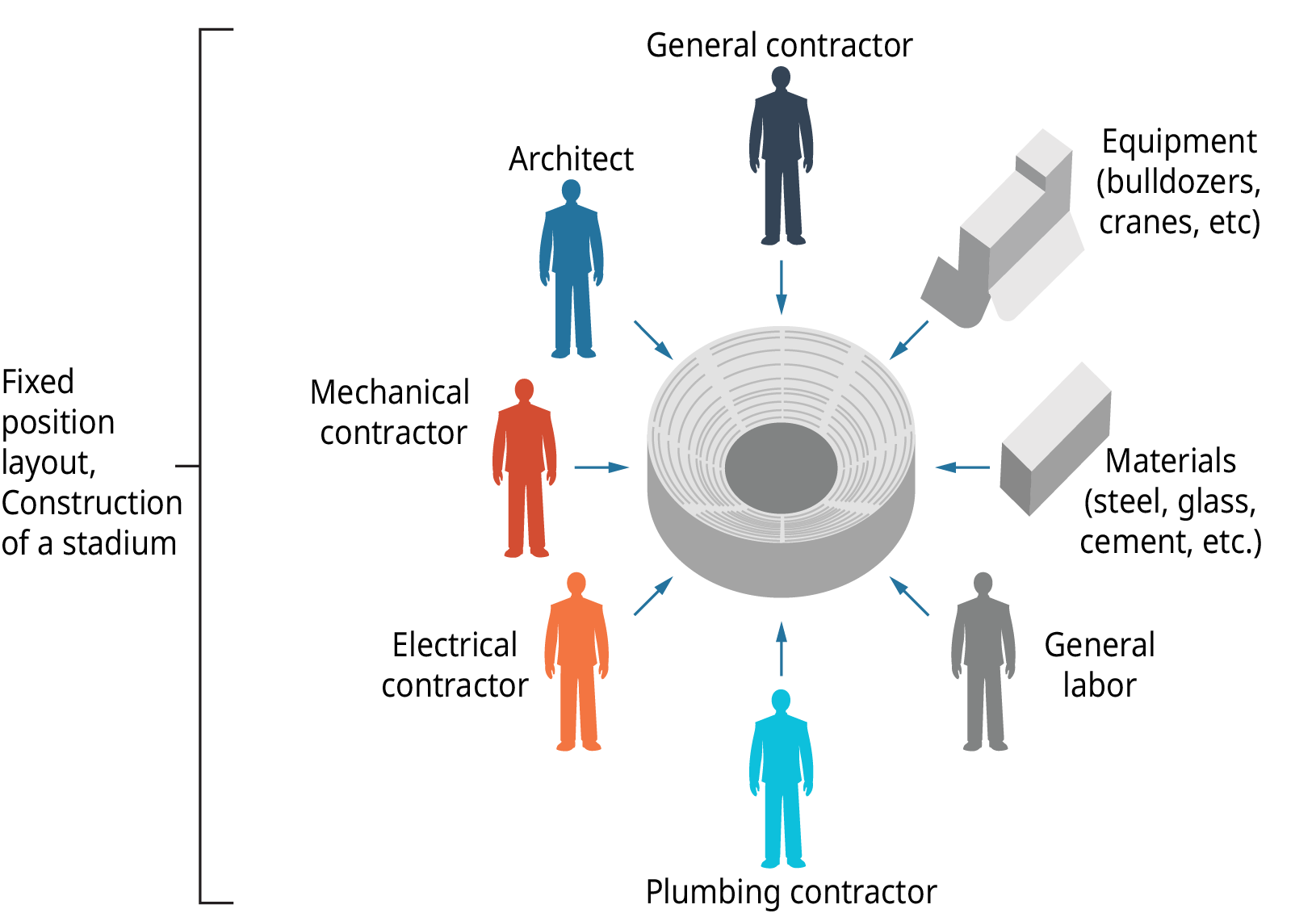

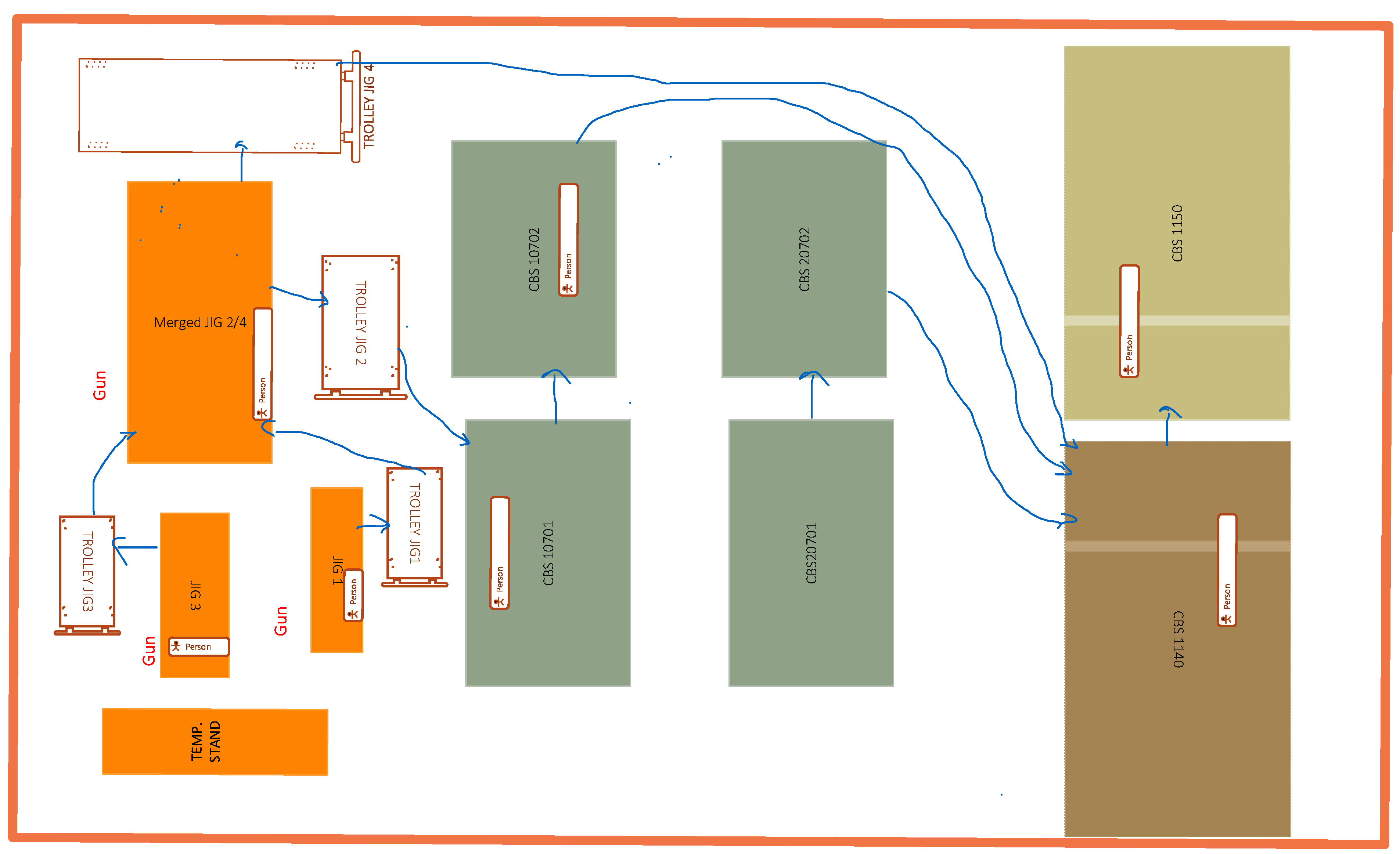

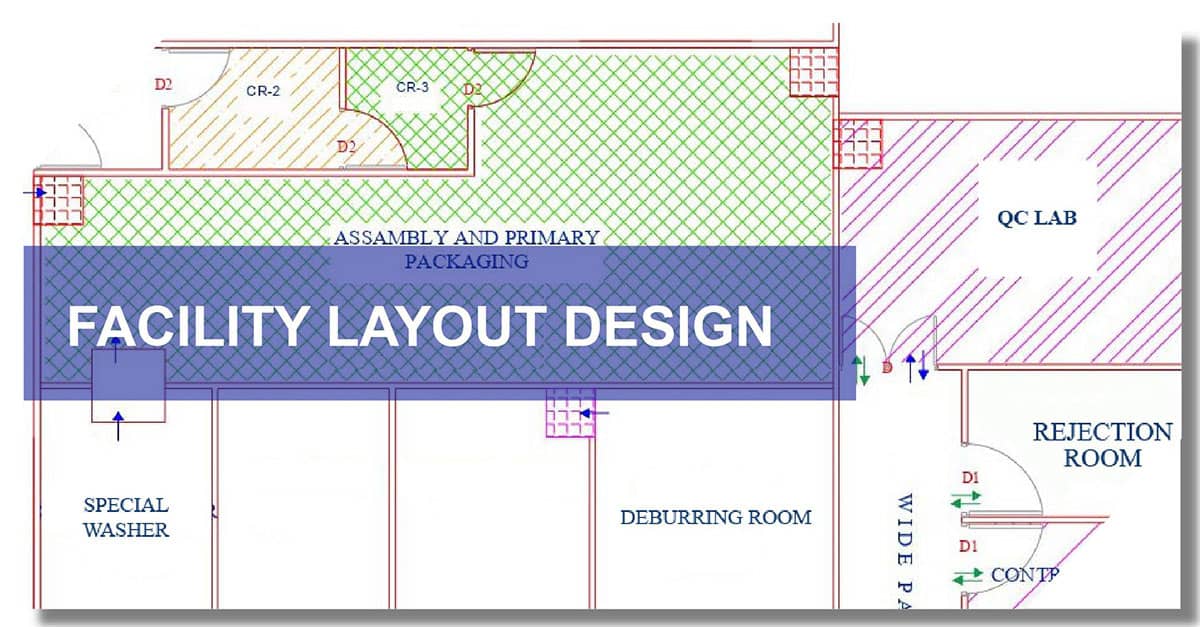

The physical layout of a facility is perhaps the most fundamental determinant of throughput. An efficient layout minimizes unnecessary movement, reduces distances between workstations, and creates clear pathways for the flow of materials and personnel. Poorly designed layouts, on the other hand, can lead to congestion, backtracking, and significant delays.

One common strategy is to implement a linear flow, where processes are arranged in a sequential order, moving materials or products through each stage without interruption. However, the optimal layout depends heavily on the specific operations and constraints of the facility.

For example, a hospital emergency room might prioritize a decentralized layout with multiple access points to critical resources, while a manufacturing plant might benefit from a highly centralized assembly line.

Technological Integration

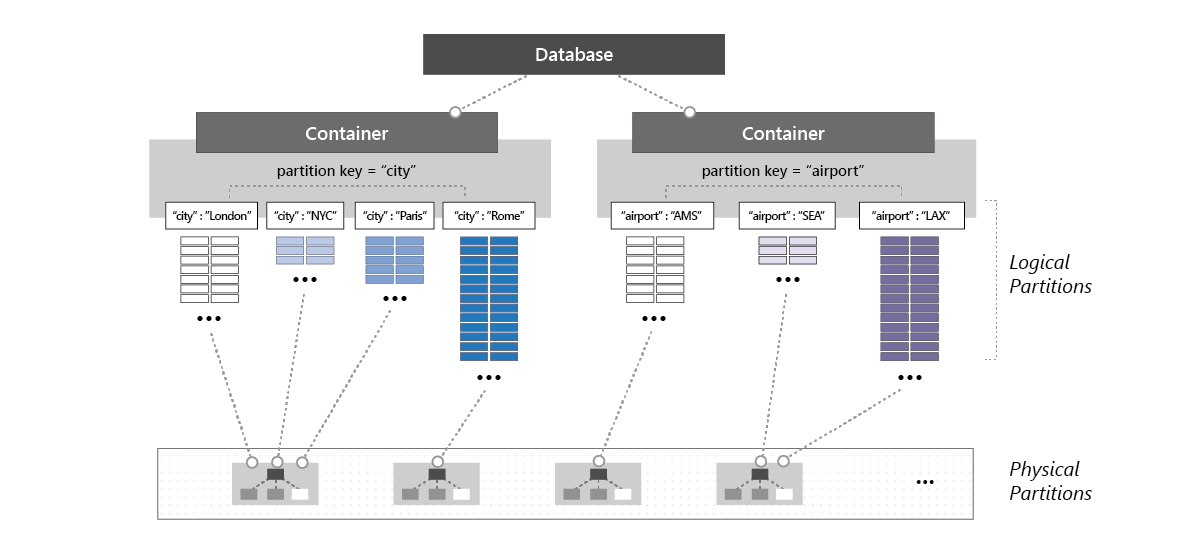

Technology plays an increasingly vital role in boosting throughput. Automation systems, such as robotic arms and automated guided vehicles (AGVs), can perform repetitive tasks with greater speed and precision than humans.

Moreover, data analytics and real-time monitoring systems provide valuable insights into bottlenecks and inefficiencies, allowing facility managers to make data-driven decisions. The use of digital twins, virtual replicas of physical facilities, is also gaining traction as a tool for simulating and optimizing throughput before construction even begins, according to a report by Accenture.

Advanced technology can dramatically improve efficiency. For example, automated sorting systems in warehouses can increase the speed and accuracy of order fulfillment, leading to faster delivery times and increased customer satisfaction.

Process Design and Standardization

Even with an optimized layout and advanced technology, a poorly designed process can significantly impede throughput. Standardizing processes, streamlining workflows, and eliminating unnecessary steps are crucial for maximizing efficiency.

Lean manufacturing principles, such as minimizing waste and maximizing value, are often applied to improve process design. This often involves identifying and eliminating non-value-added activities, such as unnecessary transportation, waiting times, and defects.

By simplifying and standardizing processes, facilities can reduce variability, improve predictability, and increase overall throughput. The Six Sigma methodology is another tool commonly used to reduce process variation and improve quality, which in turn contributes to higher throughput.

Human Factors and Ergonomics

While technology is important, human factors cannot be overlooked. The design of workstations, the provision of adequate lighting and ventilation, and the implementation of ergonomic principles are all critical for ensuring worker comfort and productivity. OSHA (Occupational Safety and Health Administration) provides guidelines and regulations on workplace safety and ergonomics.

Fatigue, discomfort, and stress can significantly reduce worker performance and increase the risk of errors, ultimately impacting throughput. By prioritizing human factors, facilities can create a more productive and safer working environment.

Investing in employee training and providing regular breaks can also contribute to improved throughput. A motivated and well-trained workforce is essential for maximizing the efficiency of any facility.

Measuring and Monitoring Throughput

Measuring and monitoring throughput is essential for identifying areas for improvement. Key performance indicators (KPIs) should be established to track throughput over time and to assess the effectiveness of design changes.

Common metrics include the number of units produced per hour, the average cycle time, and the overall equipment effectiveness (OEE). Real-time monitoring systems can provide immediate feedback on performance, allowing facility managers to quickly identify and address bottlenecks.

Data analysis tools can be used to identify trends and patterns in throughput data, providing valuable insights into the factors that are influencing performance. Continuous monitoring and analysis are crucial for maintaining and improving throughput over time.

The Future of Throughput Optimization

The future of throughput optimization will likely be driven by further advancements in technology and data analytics. The integration of artificial intelligence (AI) and machine learning (ML) will enable facilities to automate more complex tasks and to predict and prevent bottlenecks before they occur.

IoT (Internet of Things) sensors will provide a wealth of data on equipment performance, material flow, and worker activity, allowing for more precise and data-driven decision-making. The use of virtual reality (VR) and augmented reality (AR) technologies will also become more prevalent in facility design and training.

As facilities become increasingly complex and interconnected, the ability to optimize throughput will be critical for maintaining competitiveness. By embracing new technologies and adopting a data-driven approach, facilities can unlock significant gains in efficiency and productivity.

Conclusion

In conclusion, throughput is a critical metric for facility design that directly impacts a company's bottom line. By carefully considering layout, technology, process design, and human factors, facilities can optimize throughput and achieve significant improvements in efficiency and productivity. As technology continues to evolve, the potential for further throughput optimization is immense, offering businesses a powerful tool for staying ahead in today's competitive landscape.

-768.jpg)