Maintenance And Repairs Is An Operations Activity That Includes

Maintaining operational efficiency is paramount for any organization, regardless of size or industry. A critical, often unseen, component of this efficiency lies in maintenance and repairs. These activities, encompassing everything from routine inspections to emergency fixes, are fundamental to ensuring smooth operations, minimizing downtime, and maximizing the lifespan of assets.

Understanding maintenance and repairs as a core operations activity is crucial because it directly impacts productivity, profitability, and even safety. Neglecting this aspect can lead to cascading failures, costly disruptions, and potential hazards, making it a strategic imperative rather than a mere afterthought.

What Constitutes Maintenance and Repairs?

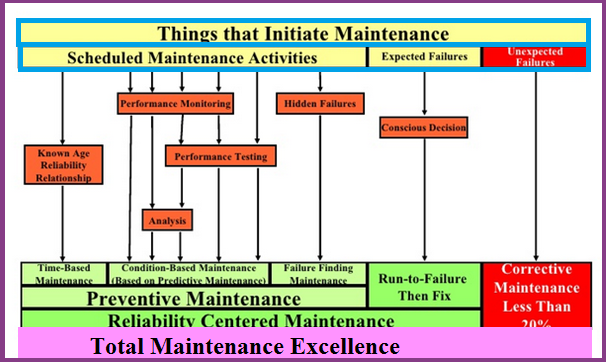

Maintenance and repairs is a broad term covering a range of tasks designed to keep equipment, machinery, and infrastructure in optimal working condition. This includes preventive maintenance, which involves scheduled inspections, cleaning, and lubrication to identify and address potential problems before they escalate.

Corrective maintenance, on the other hand, focuses on repairing or replacing components after a breakdown or malfunction. This can range from simple repairs to complex overhauls, depending on the severity of the issue.

Furthermore, predictive maintenance utilizes data analysis and monitoring techniques to anticipate failures and schedule maintenance proactively, minimizing unplanned downtime. This approach often employs technologies like sensors and machine learning to identify patterns and anomalies that indicate potential problems.

Why is Maintenance and Repairs an Operations Activity?

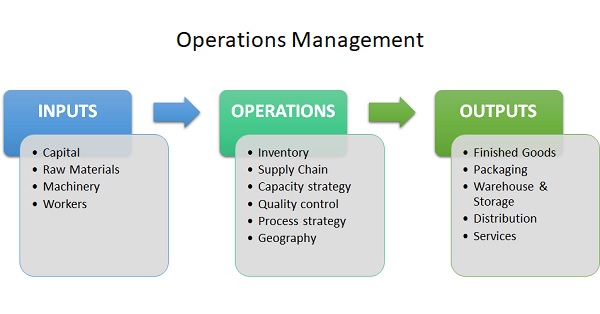

The classification of maintenance and repairs as an operations activity stems from its direct connection to the core functions of a business. Operations are defined as the activities involved in producing goods or services, and effective maintenance is essential for ensuring these activities can proceed without interruption.

When equipment breaks down, production grinds to a halt, leading to lost revenue and missed deadlines. Proactive maintenance, therefore, directly contributes to the smooth flow of operations and helps maintain productivity levels.

Beyond production, maintenance and repairs also play a critical role in safety. Well-maintained equipment is less likely to cause accidents or injuries, creating a safer working environment for employees. This is particularly important in industries like manufacturing, construction, and transportation, where equipment malfunctions can have serious consequences.

The Importance of Strategic Maintenance Management

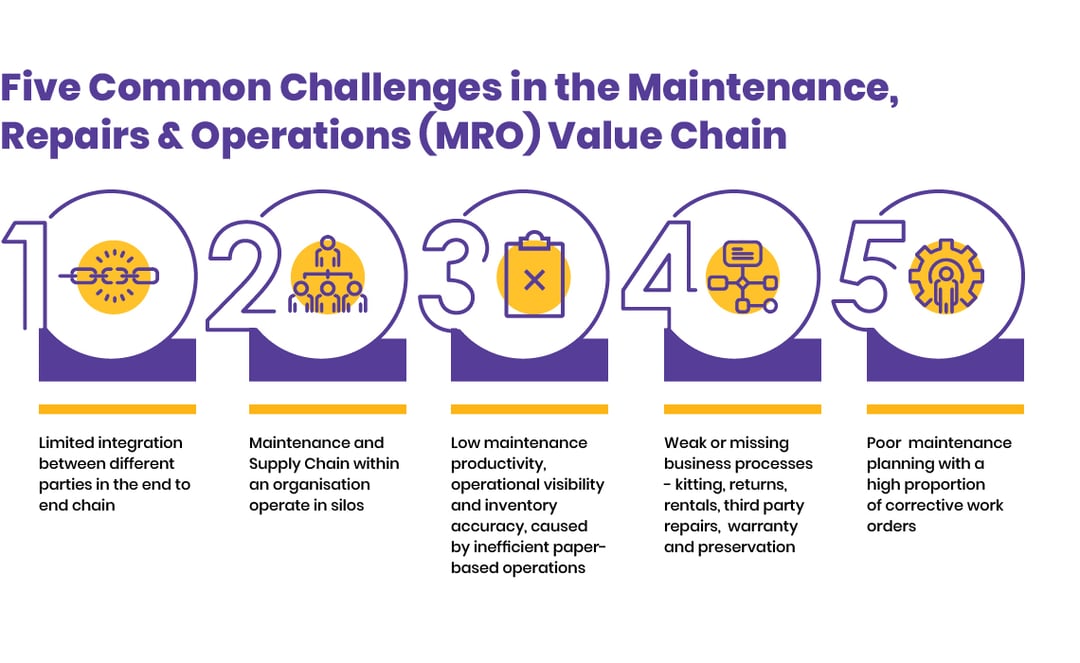

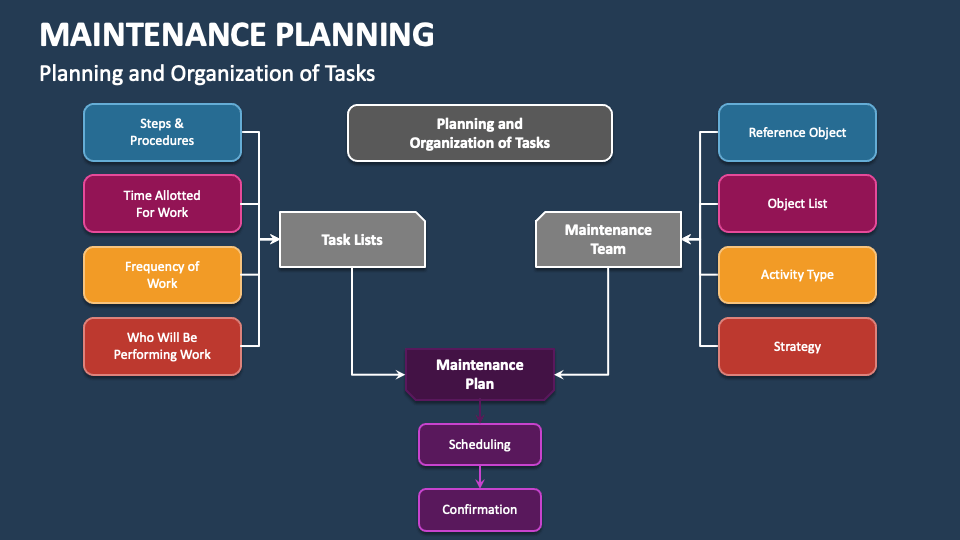

Effective maintenance and repairs requires a strategic approach that goes beyond simply fixing things when they break. It involves developing a comprehensive maintenance plan that aligns with the organization's overall business objectives.

This plan should include a schedule for preventive maintenance, procedures for responding to breakdowns, and a system for tracking maintenance activities. It should also consider factors like the age and condition of equipment, the cost of repairs, and the impact of downtime on production.

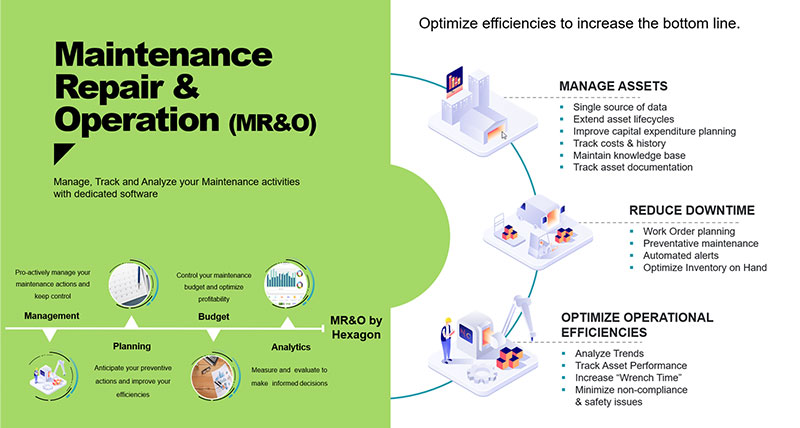

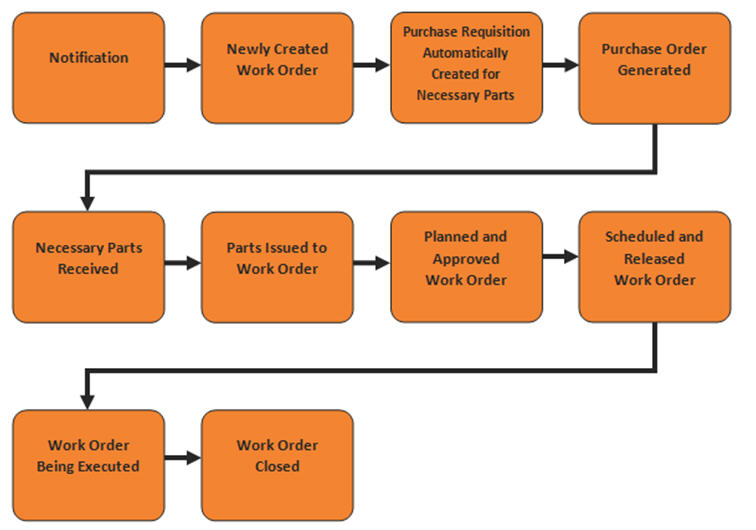

Increasingly, organizations are turning to computerized maintenance management systems (CMMS) to streamline their maintenance operations. These systems provide a centralized platform for managing work orders, tracking inventory, and analyzing maintenance data, enabling organizations to make more informed decisions about maintenance planning and resource allocation.

Potential Impact on Businesses and Society

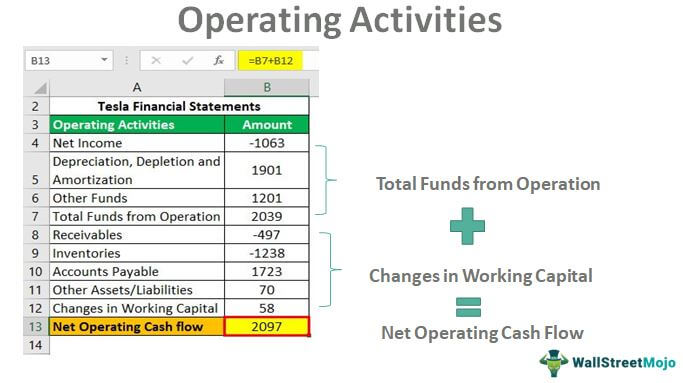

The impact of effective maintenance and repairs extends beyond individual businesses. By minimizing downtime and extending the lifespan of assets, it contributes to economic growth and resource conservation.

Reduced downtime translates to increased productivity and higher profits for businesses. Extended asset lifespans reduce the need for new equipment, conserving resources and reducing waste.

Furthermore, effective maintenance practices can contribute to a more sustainable future. By keeping equipment operating efficiently, organizations can reduce their energy consumption and emissions, minimizing their environmental impact.

Conclusion

In conclusion, maintenance and repairs is not simply a technical task; it is a fundamental operations activity that directly impacts productivity, profitability, safety, and sustainability. By recognizing its strategic importance and implementing effective maintenance management practices, organizations can unlock significant benefits and ensure long-term success.

Organizations that prioritize proactive maintenance are better positioned to minimize disruptions, reduce costs, and create a safer, more efficient working environment. This, in turn, contributes to a stronger economy and a more sustainable future for all.