Metal Finishing For The Biotechnology Industry

The biotechnology industry, known for its stringent requirements for cleanliness, precision, and compliance, is increasingly reliant on specialized metal finishing processes. These processes, often unseen, are critical in ensuring the performance, reliability, and safety of biopharmaceutical manufacturing equipment and research instruments.

Metal finishing plays a vital role in the biotechnology sector by enhancing corrosion resistance, improving hygiene, and achieving the necessary surface characteristics for optimal operation. From electropolishing to passivation, these techniques are becoming indispensable for meeting the industry's demanding standards.

The Importance of Metal Finishing

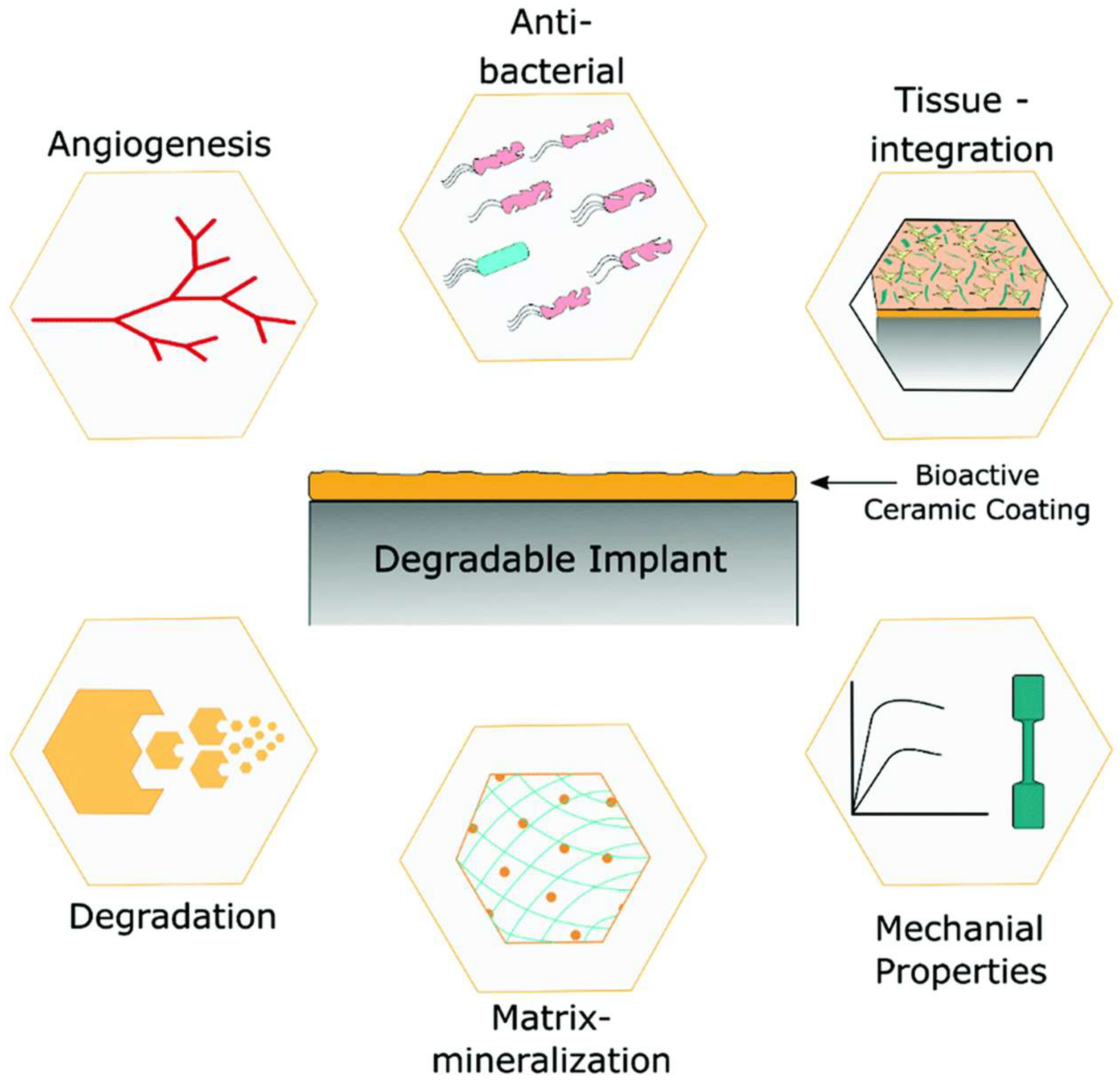

The biotechnology industry faces unique challenges. Equipment comes into direct contact with biological materials, demanding surfaces that are exceptionally clean, resistant to corrosion, and inert.

Metal finishing techniques address these challenges head-on. They refine the surface of metals, creating barriers against contamination and deterioration. This is especially crucial for equipment used in the production of vaccines, pharmaceuticals, and other life-saving products.

Corrosion resistance is paramount. Biotechnology processes often involve harsh chemicals and extreme temperatures, accelerating corrosion. Properly finished metal components can withstand these conditions, preventing costly downtime and ensuring product integrity.

Key Metal Finishing Processes in Biotechnology

Several metal finishing processes are commonly employed in the biotechnology sector. Each process offers unique benefits and is selected based on the specific application and material.

Electropolishing is a widely used technique. It involves removing a thin layer of metal from the surface using an electrochemical process, resulting in a smoother, brighter, and more passive surface.

Electropolishing is particularly effective for stainless steel, a common material in biopharmaceutical equipment. It eliminates microscopic imperfections that can harbor bacteria and other contaminants.

Passivation is another essential process. It creates a protective oxide layer on the surface of the metal, enhancing its resistance to corrosion. This layer forms spontaneously when certain metals, like stainless steel, are exposed to oxygen or oxidizing agents.

The passivation layer is critical for preventing the release of metal ions into the process stream. This is crucial to maintain the purity of the biopharmaceutical product.

Other techniques, such as chemical cleaning and surface coating, are also employed. These processes further enhance the cleanliness and performance of metal components.

The Impact on Biopharmaceutical Manufacturing

Metal finishing directly impacts the efficiency and reliability of biopharmaceutical manufacturing. By reducing the risk of contamination and corrosion, these processes contribute to increased productivity and reduced downtime.

This translates to lower production costs and faster delivery of life-saving medications. It is also contributing to improvements in equipment lifespan.

Moreover, properly finished metal components are easier to clean and maintain. This reduces the risk of cross-contamination between batches and ensures compliance with stringent regulatory requirements. The Food and Drug Administration (FDA), among other agencies, sets rigorous standards for biopharmaceutical manufacturing, necessitating the use of effective metal finishing processes.

"Metal finishing is not just about aesthetics; it's about ensuring the integrity of the entire biopharmaceutical manufacturing process," said Dr. Anya Sharma, a materials scientist specializing in bioprocessing equipment.

The Future of Metal Finishing in Biotechnology

The demand for advanced metal finishing solutions in the biotechnology industry is expected to continue to grow. This is driven by the increasing complexity of biopharmaceutical manufacturing processes and the growing need for highly specialized equipment.

Innovations in metal finishing technology are constantly emerging. New techniques and materials are being developed to address the evolving needs of the biotechnology sector. Nanocoatings, for example, are showing promise in providing even greater levels of corrosion resistance and biocompatibility.

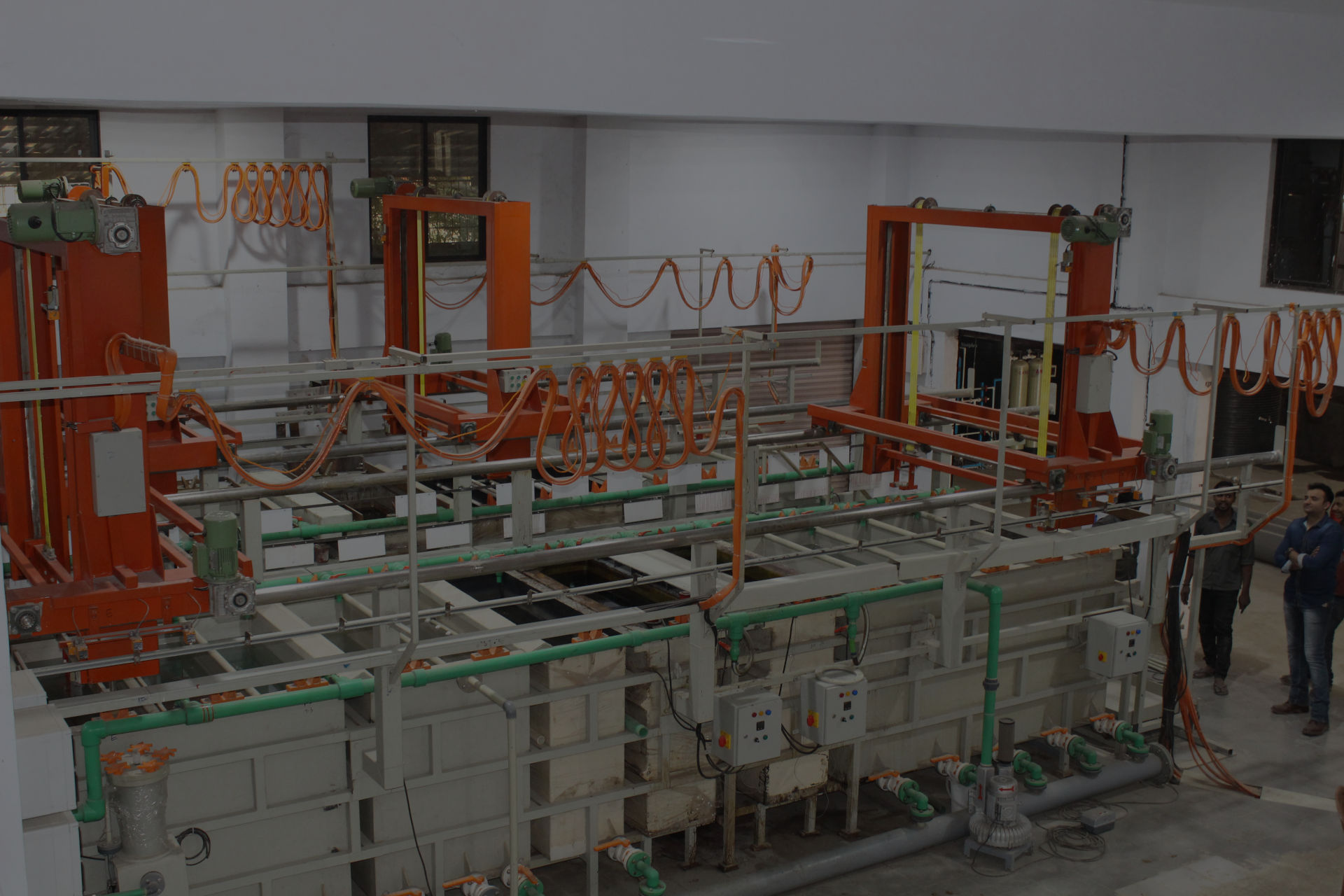

Sustainability is also becoming a key consideration. The industry is increasingly focused on developing environmentally friendly metal finishing processes that minimize waste and reduce the use of hazardous chemicals. This includes the adoption of closed-loop systems that recycle and reuse process water.

The industry is also seeking to increase the efficiency of the metal finishing processes. This includes optimizing process parameters to minimize energy consumption and reduce processing time.

A Case Study

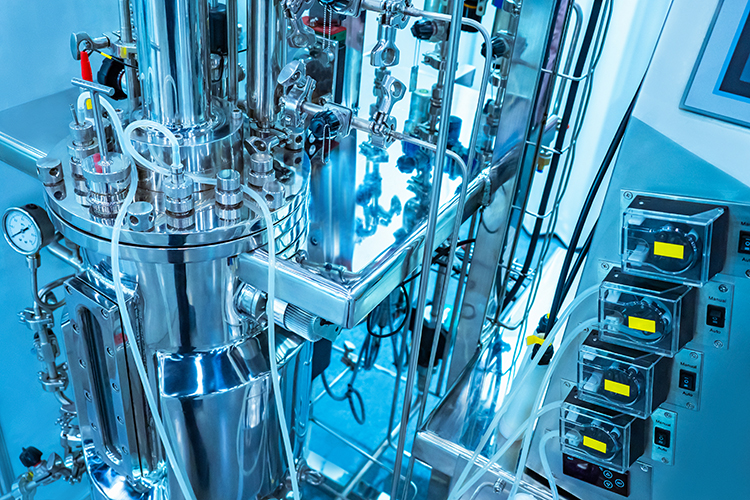

Consider a scenario involving the production of a novel vaccine. The bioreactor used to cultivate the cells must be constructed from high-grade stainless steel that has undergone rigorous electropolishing and passivation.

Without proper metal finishing, the bioreactor could corrode, releasing metal ions into the cell culture. This could compromise the purity and efficacy of the vaccine, rendering it unusable. Furthermore, surface irregularities could harbor bacteria, increasing the risk of contamination and leading to batch failures.

The cost of a single batch failure in biopharmaceutical manufacturing can be substantial. Metal finishing is therefore an important, but often overlooked part of the manufacturing process.

Conclusion

Metal finishing is an essential, but often unseen, aspect of the biotechnology industry. It enables the production of safe, effective, and reliable biopharmaceutical products.

As the biotechnology industry continues to evolve, the demand for advanced metal finishing solutions will only increase. Continued innovation in this field will be critical to supporting the development of new life-saving therapies and ensuring the integrity of biopharmaceutical manufacturing processes.

By understanding the importance of metal finishing, the biotechnology industry can ensure that equipment and components meet the highest standards of quality and performance, ultimately benefiting patients around the world.