Mitsubishi Chemical Carbon Fiber And Composites Inc

The global landscape of advanced materials is undergoing a seismic shift, with carbon fiber composites at the epicenter. Industries from aerospace to automotive are increasingly relying on these lightweight yet incredibly strong materials to drive innovation and improve performance.

At the heart of this revolution stands Mitsubishi Chemical Carbon Fiber and Composites, Inc. (MCCFC), a key player whose strategic decisions and technological advancements are shaping the future of carbon fiber manufacturing and application.

This article delves into the operations, strategies, and challenges facing MCCFC, exploring its role in a market demanding ever-greater performance and sustainability. It examines the company's impact on various sectors and investigates its plans to remain a leader in the rapidly evolving carbon fiber industry.

A Global Footprint in Carbon Fiber

MCCFC is a subsidiary of Mitsubishi Chemical Corporation, a global chemical giant. This parentage provides MCCFC with a robust foundation in research and development, manufacturing expertise, and global market access.

The company operates manufacturing facilities across the globe, including plants in the United States, Japan, and Europe. This global presence allows MCCFC to serve a diverse customer base and adapt to regional market demands.

This strategic distribution is critical for maintaining a competitive edge in the increasingly interconnected world of advanced materials.

Key Products and Applications

MCCFC's product portfolio encompasses a wide range of carbon fiber products, including standard modulus, intermediate modulus, and high modulus fibers. These fibers are tailored to meet the specific needs of different applications.

Their products are found in a myriad of industries, from aerospace, where they contribute to lighter and more fuel-efficient aircraft, to automotive, where they enhance vehicle performance and safety. Wind turbine blades also utilize MCCFC's carbon fiber to improve energy generation efficiency.

Furthermore, the company’s materials are vital in sporting goods, infrastructure, and industrial applications, showcasing the versatility of carbon fiber composites.

Aerospace Applications

The aerospace industry has been a long-standing and critical market for MCCFC. Carbon fiber composites are used extensively in aircraft structures, including wings, fuselages, and control surfaces.

The use of these materials reduces aircraft weight, leading to improved fuel efficiency and reduced emissions. Demand from aircraft manufacturers like Boeing and Airbus drives innovation and production at MCCFC.

The company's ability to supply high-quality, reliable carbon fiber is essential for maintaining stringent safety standards in the aerospace sector.

Automotive Applications

While traditionally used in high-end sports cars, carbon fiber is increasingly being adopted in mainstream automotive manufacturing. Automakers are seeking to reduce vehicle weight to meet fuel efficiency standards and improve performance.

MCCFC is working with automotive manufacturers to develop carbon fiber components for structural and non-structural applications. These range from body panels to chassis components.

The challenge lies in developing cost-effective manufacturing processes that allow for the mass production of carbon fiber parts.

Wind Energy Applications

The wind energy sector relies heavily on carbon fiber to produce longer and more efficient wind turbine blades. Longer blades capture more wind energy, increasing power generation capacity.

MCCFC provides carbon fiber for the spar caps of wind turbine blades, which provide critical structural support. As the demand for renewable energy grows, so does the demand for MCCFC's carbon fiber solutions.

Sustainable energy production goals are intrinsically linked to the innovation and availability of advanced materials like carbon fiber.

Innovation and Technology

MCCFC invests heavily in research and development to stay ahead of the curve in carbon fiber technology. The company focuses on developing new materials with improved properties and more efficient manufacturing processes.

This includes research into novel carbon fiber precursors, improved resin systems, and automated composite manufacturing techniques. MCCFC also actively collaborates with universities and research institutions to foster innovation.

Their aim is to drive down the cost of carbon fiber while enhancing its performance characteristics.

Sustainability Initiatives

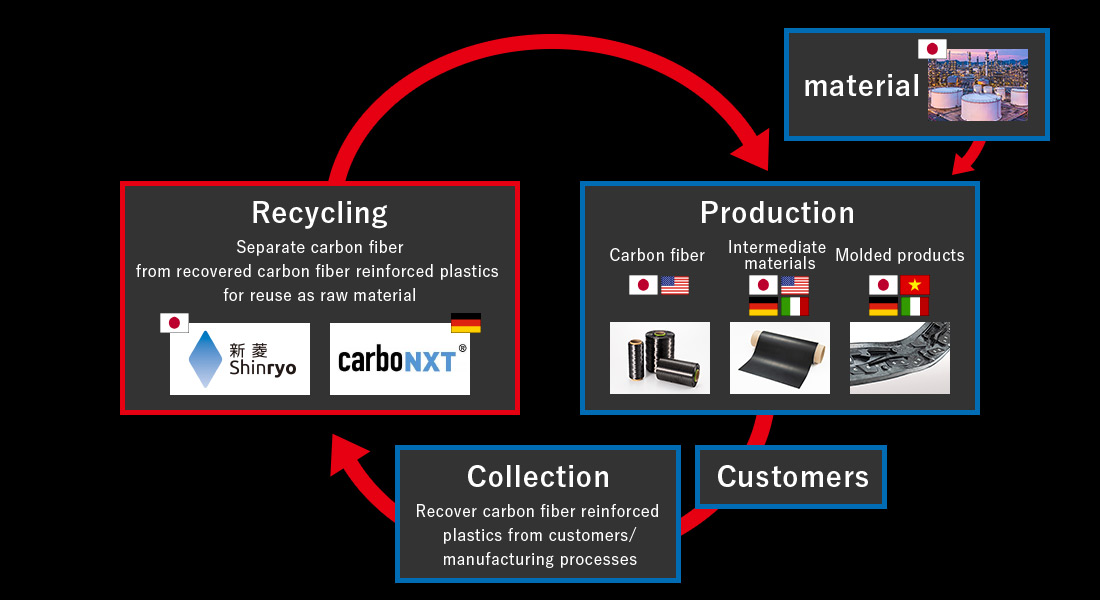

Recognizing the growing importance of sustainability, MCCFC is committed to reducing its environmental footprint. This includes efforts to reduce energy consumption in manufacturing processes and minimize waste generation.

The company is also exploring the development of bio-based carbon fiber precursors and the recycling of carbon fiber composites. Creating closed-loop systems for carbon fiber is a key focus.

These initiatives aim to align MCCFC's operations with global sustainability goals.

Challenges and Opportunities

MCCFC faces several challenges in the competitive carbon fiber market. These include fluctuating raw material prices, increasing competition from other carbon fiber manufacturers, and the need to continuously innovate.

However, the company also has significant opportunities for growth. The increasing demand for lightweight materials in various industries and the growing focus on sustainability create favorable market conditions.

Furthermore, MCCFC's strong technological capabilities and global presence position it well to capitalize on these opportunities.

The Future of MCCFC

Looking ahead, Mitsubishi Chemical Carbon Fiber and Composites, Inc. is poised to play a central role in the future of advanced materials. The company's commitment to innovation, sustainability, and customer satisfaction will be crucial for maintaining its competitive edge.

By continuing to invest in research and development and expanding its global presence, MCCFC can solidify its position as a leader in the carbon fiber industry. The company's strategic direction will shape the evolution of countless industries reliant on lightweight, high-performance materials.

Ultimately, MCCFC's success will depend on its ability to adapt to changing market demands and deliver innovative solutions that meet the evolving needs of its customers.