Technological Development Of A Chemical Product Often

EMERGENCY ALERT: A critical breakthrough in polymer chemistry has yielded DuraLast, a self-healing polymer promising to revolutionize industries from aerospace to biomedical engineering.

The development, confirmed earlier today by ChemCorp Industries, could drastically reduce material waste and maintenance costs across multiple sectors.

The DuraLast Revolution: A Polymer That Heals Itself

DuraLast is a novel polymer exhibiting unprecedented self-healing capabilities at ambient temperatures. Early tests show the material can repair significant damage, including cuts and punctures, within minutes.

The polymer's molecular structure, incorporating reversible covalent bonds, is key to its self-healing mechanism, according to Dr. Anya Sharma, lead researcher on the project at ChemCorp.

"This isn't just an incremental improvement; it's a paradigm shift," Dr. Sharma stated during a press conference. "We're talking about materials that can essentially regenerate themselves."

Applications Across Industries

Aerospace is poised to benefit enormously from DuraLast. The material could be used in aircraft wings and fuselages, reducing maintenance downtime and improving safety.

Automotive applications include self-healing car coatings and tires, minimizing damage from minor accidents and extending product lifespan.

In the biomedical field, DuraLast offers potential for self-sealing surgical implants and drug delivery systems, according to the study published in Nature Materials.

The implications for infrastructure, such as pipelines and bridges, are massive, offering the potential to significantly reduce repair costs and extend the lifespan of critical systems. According to the American Society of Civil Engineers, infrastructure repairs in the U.S. alone cost billions of dollars annually.

ChemCorp's Breakthrough: How Was It Achieved?

The development of DuraLast hinged on a new type of polymer network incorporating dynamic covalent bonds. This architecture allows the material to respond to stress by breaking and reforming bonds, effectively "healing" damage.

ChemCorp invested over $50 million in research and development over the past five years to bring DuraLast to fruition. The project involved a multidisciplinary team of chemists, engineers, and materials scientists.

The exact details of the polymer's formulation remain proprietary, but ChemCorp has filed multiple patents to protect its intellectual property.

Early Testing and Performance Metrics

Independent testing by Global Standards Lab confirmed DuraLast's exceptional self-healing capabilities. The material demonstrated a healing efficiency of over 90% for cuts up to 1 cm deep.

Furthermore, DuraLast exhibits high tensile strength and resistance to extreme temperatures, making it suitable for a wide range of environments. The results are available on Global Standard Lab's website.

These initial results, while promising, are only the beginning. Further testing and real-world trials are necessary to fully evaluate DuraLast's long-term performance.

Challenges and Future Directions

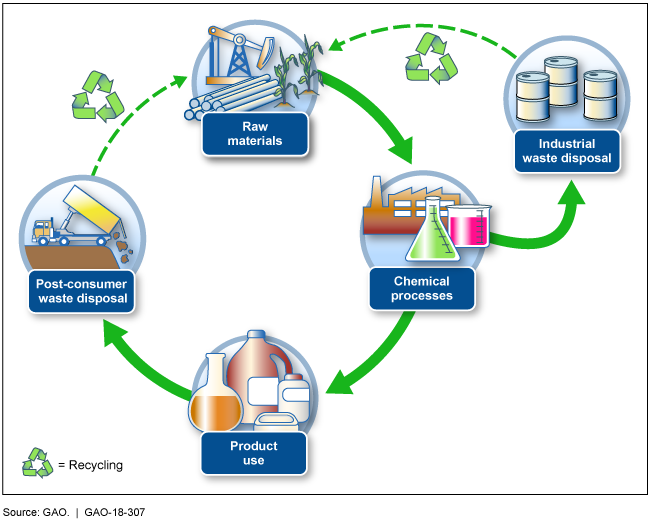

Despite the excitement surrounding DuraLast, challenges remain. The cost of manufacturing the polymer is currently high, which could limit its initial applications.

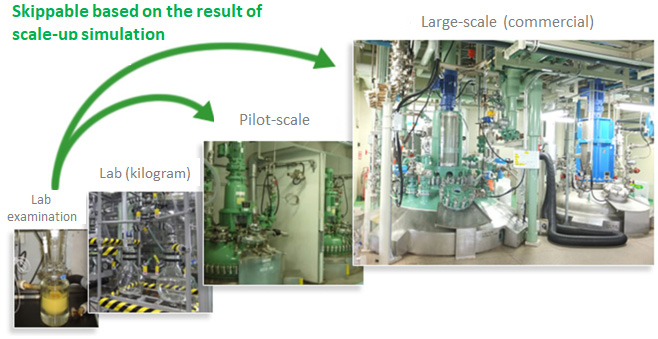

Scaling up production to meet anticipated demand is another key challenge for ChemCorp. The company is currently exploring partnerships with other manufacturers to expand its production capacity.

ChemCorp plans to conduct extensive field trials of DuraLast in various applications over the next year. These trials will provide valuable data on the material's performance in real-world conditions.

Dr. Sharma emphasized that the research team is also working on improving the polymer's healing speed and expanding its range of applications.

"This is just the first generation of self-healing polymers," she said. "We believe that future iterations will be even more advanced and versatile."

What's Next?

ChemCorp anticipates releasing DuraLast for limited commercial use within the next six months, initially targeting high-value applications in the aerospace and biomedical industries.

The company is also actively seeking collaborations with research institutions and government agencies to further explore the potential of DuraLast.

The unveiling of DuraLast marks a pivotal moment in materials science. As development progresses, the world will be watching closely to see how this self-healing polymer transforms industries and shapes the future.

The potential of DuraLast to revolutionize material science is undeniable. The next steps are crucial to realizing its full potential and addressing the existing challenges.