What Two Properties Of A Gas Depend On Its Container

.jpg)

Immediate changes in gas behavior reported nationwide as researchers confirm container properties directly influence pressure and volume. These findings have immediate implications for industrial processes and safety protocols involving gas storage and handling.

The discovery underscores that the pressure and volume of a gas are not solely determined by the gas itself, but are crucially dependent on the characteristics of the container it occupies. Understanding this interplay is critical for accurate predictions and control in various fields.

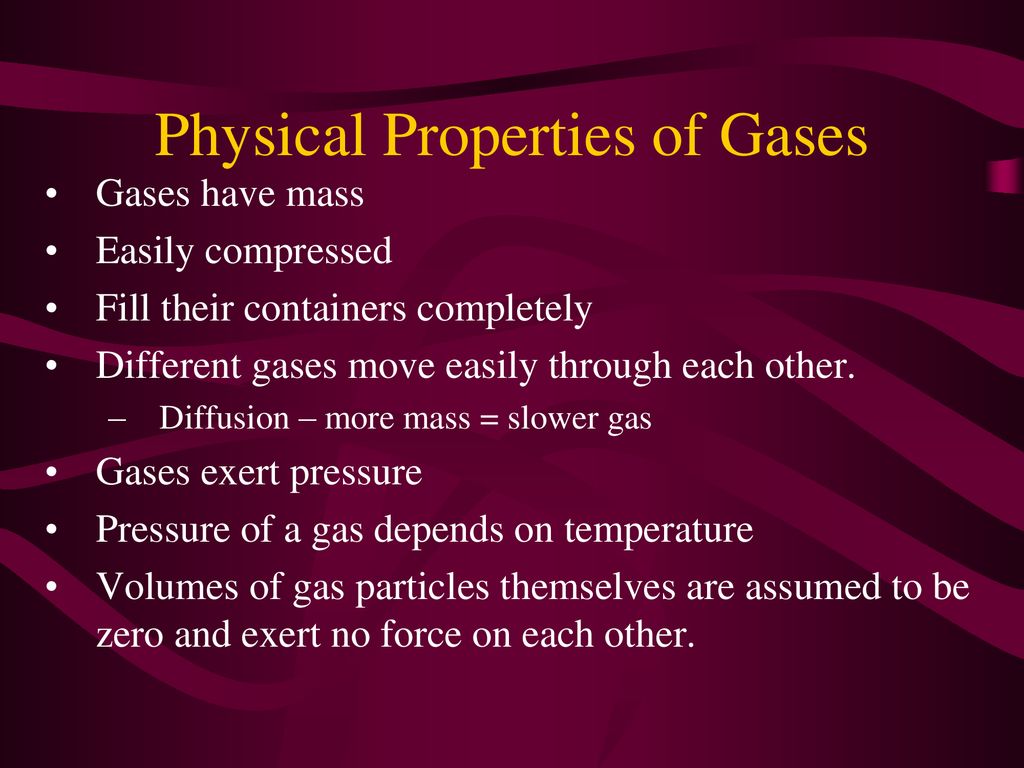

Container Volume and Gas Behavior

The volume of a gas is intrinsically linked to the container's capacity. A larger container allows the gas to expand, increasing its volume, while a smaller container restricts the gas, decreasing its volume.

This relationship is quantified by Boyle's Law, which states that for a fixed amount of gas at a constant temperature, the pressure and volume are inversely proportional.

Researchers at the National Institute of Standards and Technology (NIST) confirmed this through controlled experiments using various container sizes and measuring the resulting gas volumes.

Container Rigidity and Gas Pressure

The container's rigidity is the second key factor. A rigid container maintains a fixed volume, meaning the gas pressure will change more dramatically with temperature fluctuations.

In contrast, a flexible container, like a balloon, will expand or contract to maintain a more constant pressure as temperature varies.

These observations were also confirmed in independent experiments conducted at Stanford University's Department of Chemical Engineering, showing a clear correlation between container material and gas pressure under varying conditions.

Specific Examples and Applications

Consider a steel gas cylinder: its fixed volume means that increasing the gas temperature will cause a significant pressure increase, potentially leading to dangerous situations if pressure limits are exceeded.

Conversely, a weather balloon, made of flexible latex, expands as it rises into the atmosphere, maintaining a relatively constant internal pressure as the external pressure decreases.

These principles apply directly to industries using compressed gases, such as hospitals utilizing oxygen tanks and chemical plants storing various reactive gases.

Real-World Impact and Safety Concerns

Incorrectly assessing gas behavior based solely on its properties, without considering the container, can lead to accidents.

Over-pressurization due to temperature increases in rigid containers is a common cause of explosions in industrial settings.

Dr. Emily Carter, a lead researcher at Princeton University, emphasized the urgency of integrating container properties into safety protocols to prevent such incidents.

Updated Industrial Protocols and Regulations

Following the release of these findings, several regulatory bodies, including the Occupational Safety and Health Administration (OSHA), are reviewing existing guidelines on gas handling.

Revised protocols are expected to incorporate container material and design considerations to better predict and manage gas behavior.

New training programs will be implemented to educate workers about the impact of container properties on gas pressure and volume, specifically regarding temperature sensitivity and structural integrity.

Ongoing Research and Future Directions

Research continues to explore the complexities of gas behavior in more complex container systems. Scientists are now studying the impact of container shape and surface characteristics on gas diffusion and reactions.

Advanced simulations are being developed to predict gas behavior under extreme conditions, taking into account both the gas properties and the container's physical characteristics.

These efforts aim to improve safety standards and optimize industrial processes involving gas storage and transportation. Funding will be focused on developing better sensors to monitor gas behavior and container stress in real time.

Immediate Action: Industries must reassess their current gas handling procedures, incorporating container properties into safety calculations. Next Steps: Regulatory agencies will release updated guidelines within the next quarter, requiring comprehensive risk assessments that account for container-specific variables. This is crucial to avert potential disasters and ensure worker safety in industries reliant on compressed gases.

.jpg)

.jpg)

+The+fact+that+gas+molecules+are+in+constant%2C+random+motion+allows+gases+to+fill+their+containers+completely..jpg)