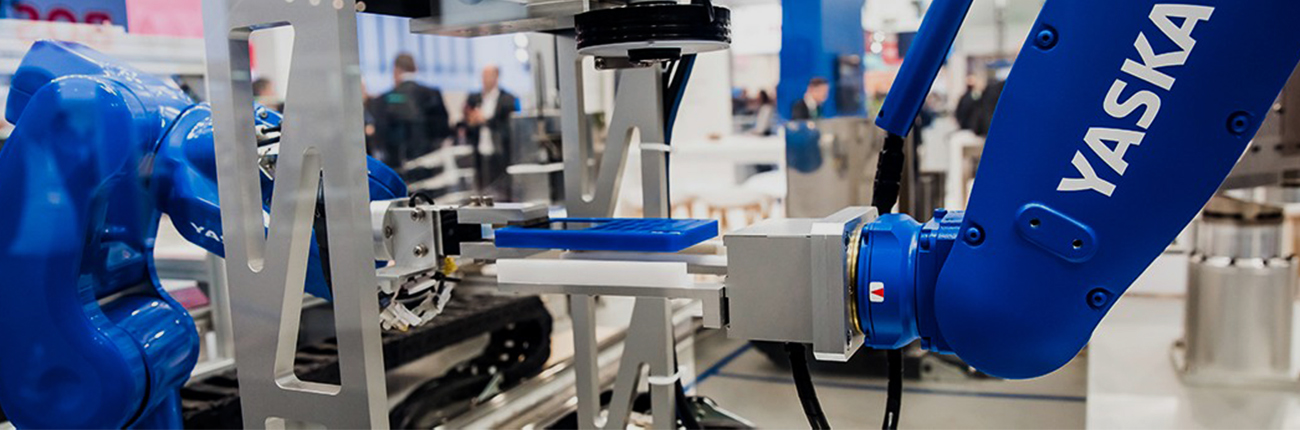

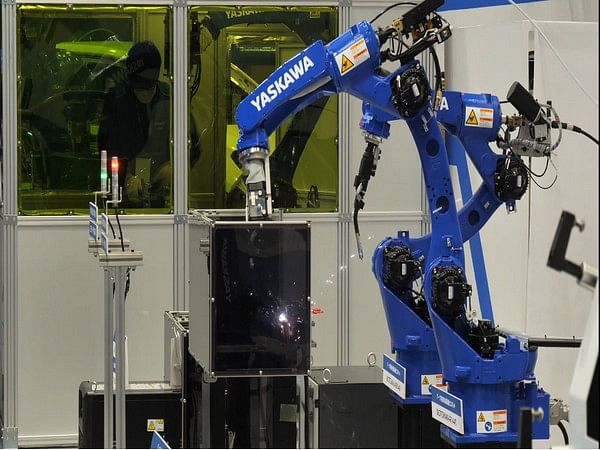

Yaskawa Electric Corporation Samsung Production Line

Production at Samsung Electronics' key memory chip line in South Korea experienced an unexpected disruption earlier this week due to an equipment malfunction involving robots supplied by Yaskawa Electric Corporation. The incident has triggered immediate concerns about potential supply chain impacts and price volatility in the global semiconductor market.

The disruption, while seemingly contained, highlights the critical role of automation and the vulnerability of highly integrated production lines to unforeseen technical issues. Investigations are underway to determine the root cause and prevent future occurrences.

Incident Overview

On Tuesday, October 29, 2024, a fault occurred within a robotic arm manufactured by Yaskawa Electric on one of Samsung's primary DRAM production lines in Hwaseong, South Korea.

The malfunction resulted in a temporary halt to a segment of the production process, impacting the output of a specific type of high-density DRAM chip. Initial reports suggest that the robotic arm experienced a software glitch causing it to misalign during a crucial handling stage.

Samsung immediately activated its emergency response protocols, isolating the affected area and initiating troubleshooting procedures.

Impact on Production

Samsung has confirmed that the disruption lasted approximately 12 hours. The company estimates that the downtime resulted in a loss of approximately 2% of the weekly output for that specific DRAM line.

While the overall impact is considered manageable, industry analysts are closely monitoring the situation for any lingering effects on supply and pricing, especially given the current global chip shortage.

"Any disruption, even a minor one, can have ripple effects in this tightly constrained market," said analyst firm Gartner in a statement released Wednesday. "We're urging cautious optimism while we await further details on the incident's long-term consequences."

Yaskawa Electric's Response

Yaskawa Electric Corporation has dispatched a team of engineers to the Samsung facility to assist in the investigation and provide technical support. The company issued a brief statement acknowledging the incident and reaffirming its commitment to working closely with Samsung to resolve the issue promptly.

"We are taking this matter very seriously and are dedicated to ensuring the reliability and safety of our products," a Yaskawa spokesperson said.

Yaskawa is conducting its own internal investigation to determine the cause of the malfunction and implement preventative measures to avoid similar incidents in the future. The company is under pressure to demonstrate the robustness of its robotic systems, particularly in highly demanding manufacturing environments.

Root Cause Analysis

Preliminary findings suggest that the software glitch was triggered by an unforeseen interaction between the Yaskawa robot's control system and Samsung's integrated manufacturing execution system (MES).

Investigators are examining the software code for vulnerabilities and exploring potential compatibility issues between the two systems. The inquiry also includes a review of maintenance logs and operating procedures to identify any human factors that may have contributed to the problem.

The possibility of a cyberattack has not been ruled out, although there is currently no evidence to suggest that the malfunction was the result of malicious activity.

Market Implications

The news of the production disruption at Samsung has caused minor fluctuations in the spot market for DRAM chips. While prices have not spiked dramatically, there is increased nervousness among buyers who are already facing tight supplies and rising costs.

Several industry experts have cautioned against overreacting, emphasizing that the disruption was relatively short-lived and that Samsung has the capacity to compensate for the lost output.

"The key will be how quickly Samsung and Yaskawa can identify and resolve the root cause," said Dan Hutcheson, CEO of TechInsights. "A swift resolution will minimize the potential impact on the market."

The incident serves as a reminder of the inherent risks associated with highly automated production lines. While automation offers significant benefits in terms of efficiency and productivity, it also creates new points of failure that can disrupt operations and impact supply chains.

Next Steps and Ongoing Developments

Samsung has resumed full production at the affected DRAM line and is working to restore its inventory levels to normal. Yaskawa Electric is providing ongoing technical support and collaborating with Samsung on a comprehensive review of the robotic system's performance.

Both companies are expected to release a joint statement in the coming days outlining the findings of their investigations and the measures they are taking to prevent future disruptions.

The semiconductor industry will be closely watching the outcome of this incident, as it could have broader implications for the adoption of automation technologies and the resilience of global supply chains.