How Much Does It Cost For An Engine Swap

The allure of enhanced horsepower or a more reliable drivetrain often leads car enthusiasts to consider an engine swap. But the burning question remains: what's the actual cost of this automotive upgrade? The answer, as with most things automotive, is complex and depends heavily on various factors.

An engine swap, at its core, involves removing the existing engine from a vehicle and replacing it with a different one. Understanding the associated costs is crucial for anyone contemplating this significant modification.

The Price Breakdown: Factors Influencing Cost

The final bill for an engine swap can range from a few thousand dollars to well over ten thousand, depending on the specifics of the project.

Several key elements contribute to this wide price range.

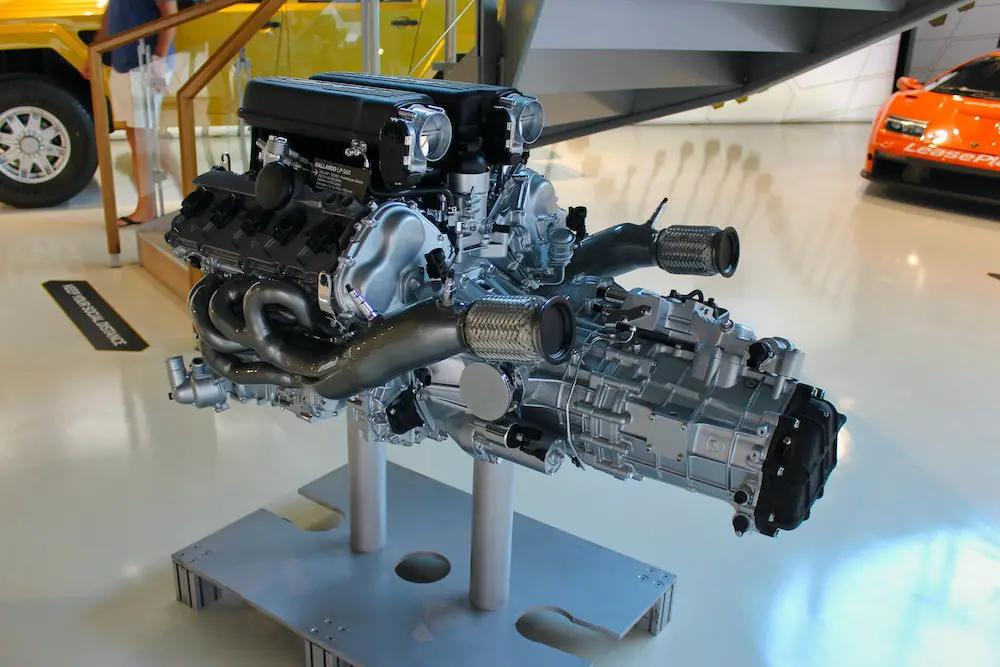

Engine Acquisition Costs

The heart of the swap, the engine itself, represents a significant portion of the overall expense. A brand new crate engine from a manufacturer like General Motors or Ford can easily cost between $5,000 and $10,000 or more, depending on its specifications and intended performance.

Alternatively, a used engine from a salvage yard or private seller might offer a more budget-friendly option, potentially costing between $1,000 and $4,000.

However, used engines come with the inherent risk of unknown history and potential future repairs.

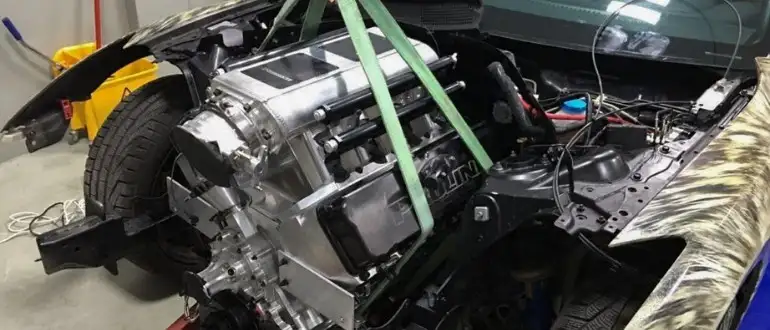

Labor Costs and Expertise

Professional installation by a qualified mechanic is highly recommended for engine swaps. Labor costs can vary considerably based on the complexity of the swap and the mechanic's hourly rate. Expect to pay anywhere from $2,000 to $5,000 or more for labor, depending on the specific challenges involved.

The complexity of the swap greatly affects labor. Swapping an engine with a similar model within the same vehicle platform will be simpler and cheaper than adapting an engine from a completely different make and model.

This is because it requires custom fabrication and wiring modifications.

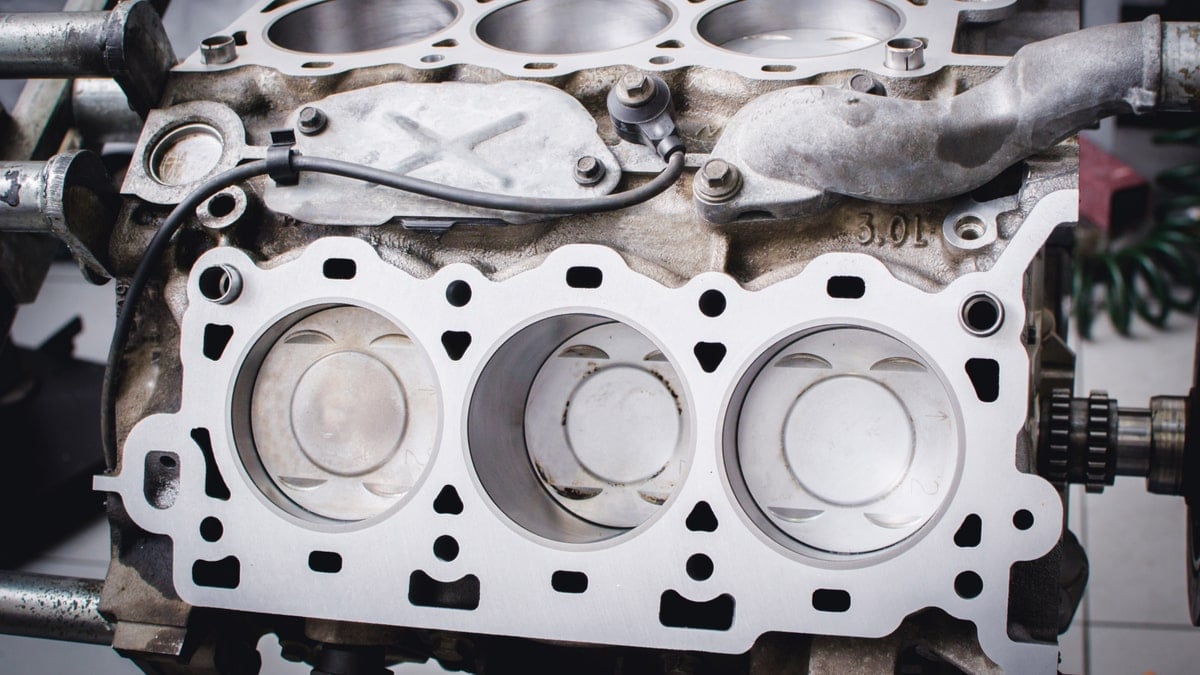

Supporting Components and Modifications

Beyond the engine and labor, numerous supporting components and modifications often become necessary. These could include a new wiring harness, engine mounts, cooling system upgrades (radiator, hoses), fuel system modifications (fuel pump, lines), exhaust system adjustments, and transmission upgrades to handle the increased power output.

Depending on the vehicle, these additional parts and modifications can add another $1,000 to $3,000 to the total cost.

Unexpected Issues and Contingencies

Engine swaps are rarely without surprises. Unexpected issues, such as unforeseen compatibility problems or the discovery of worn-out components during the installation process, can lead to cost overruns.

It's wise to budget for contingencies to cover any unforeseen expenses that may arise during the swap.

The DIY Approach: A Cost-Saving Measure?

For mechanically inclined individuals, a do-it-yourself (DIY) engine swap might seem like a way to save money. While it can potentially reduce labor costs significantly, it also comes with inherent risks.

A successful DIY swap requires extensive knowledge of automotive systems, access to specialized tools, and a significant time commitment.

Improper installation can lead to serious mechanical problems or even safety hazards, potentially costing more in the long run than hiring a professional.

Conclusion: Weighing the Costs and Benefits

An engine swap is a significant investment that requires careful planning and consideration. Understanding the various cost factors involved is crucial for making an informed decision.

Whether opting for a professional installation or a DIY approach, thorough research and a realistic budget are essential for a successful and satisfying engine swap experience.

Ultimately, the decision hinges on individual needs, skills, and financial resources.