Inbound Logistics Include Which Of The Following

Supply chains are facing unprecedented scrutiny. The question on everyone's mind: What exactly constitutes inbound logistics, and how can it be optimized?

This article cuts through the complexity to deliver a clear, concise breakdown of the core components of inbound logistics, essential for businesses navigating today's turbulent market.

Understanding Inbound Logistics: The Essentials

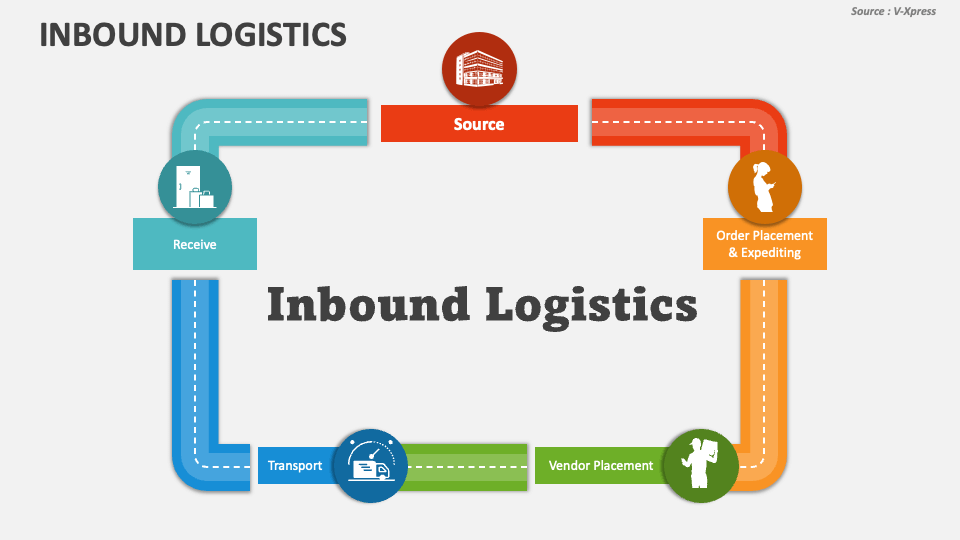

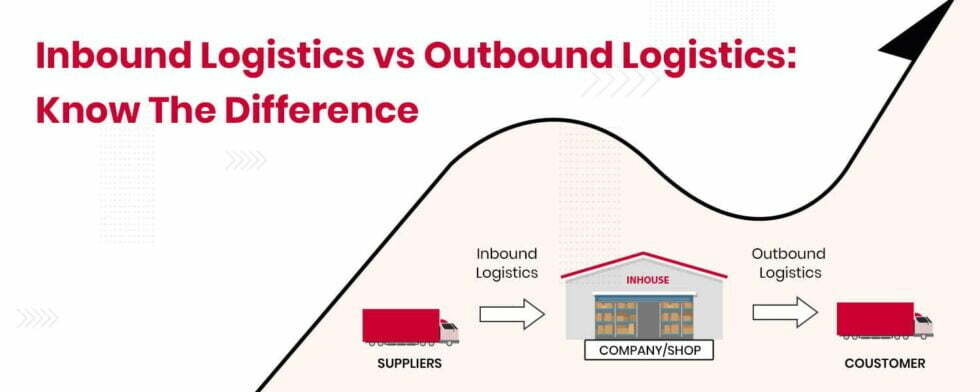

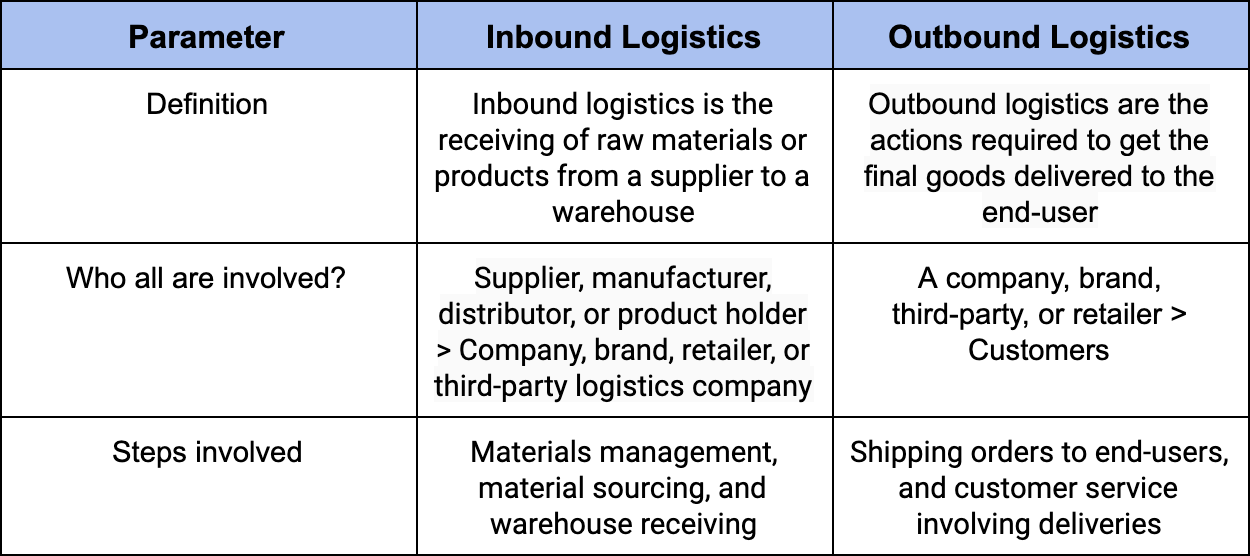

Inbound logistics encompasses all activities related to receiving, storing, and disseminating incoming goods and materials. These are materials coming into your company from your suppliers.

It's the crucial first step in the supply chain, directly impacting efficiency and cost-effectiveness.

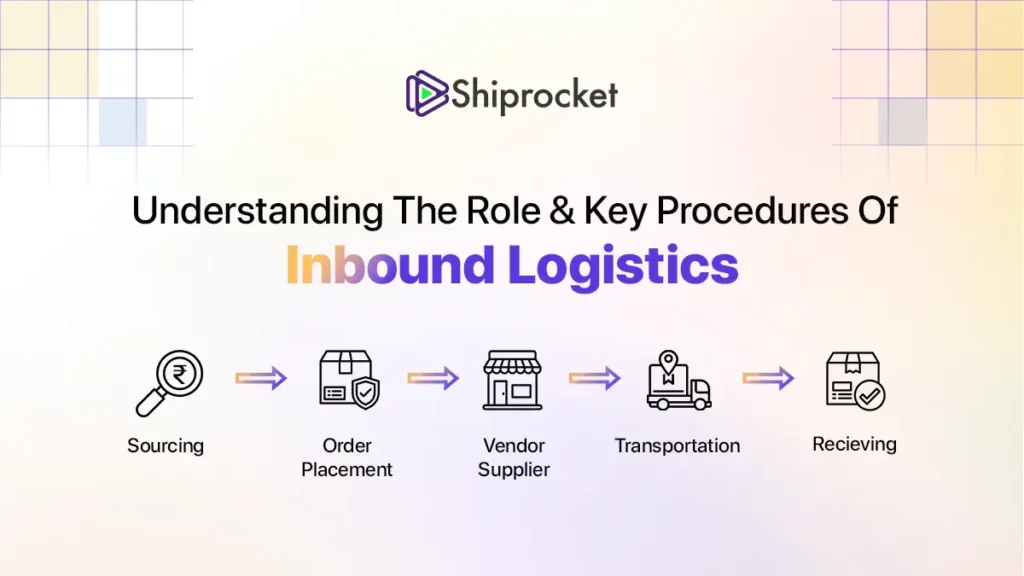

Key Components Demystified

Let's break down the core elements of inbound logistics.

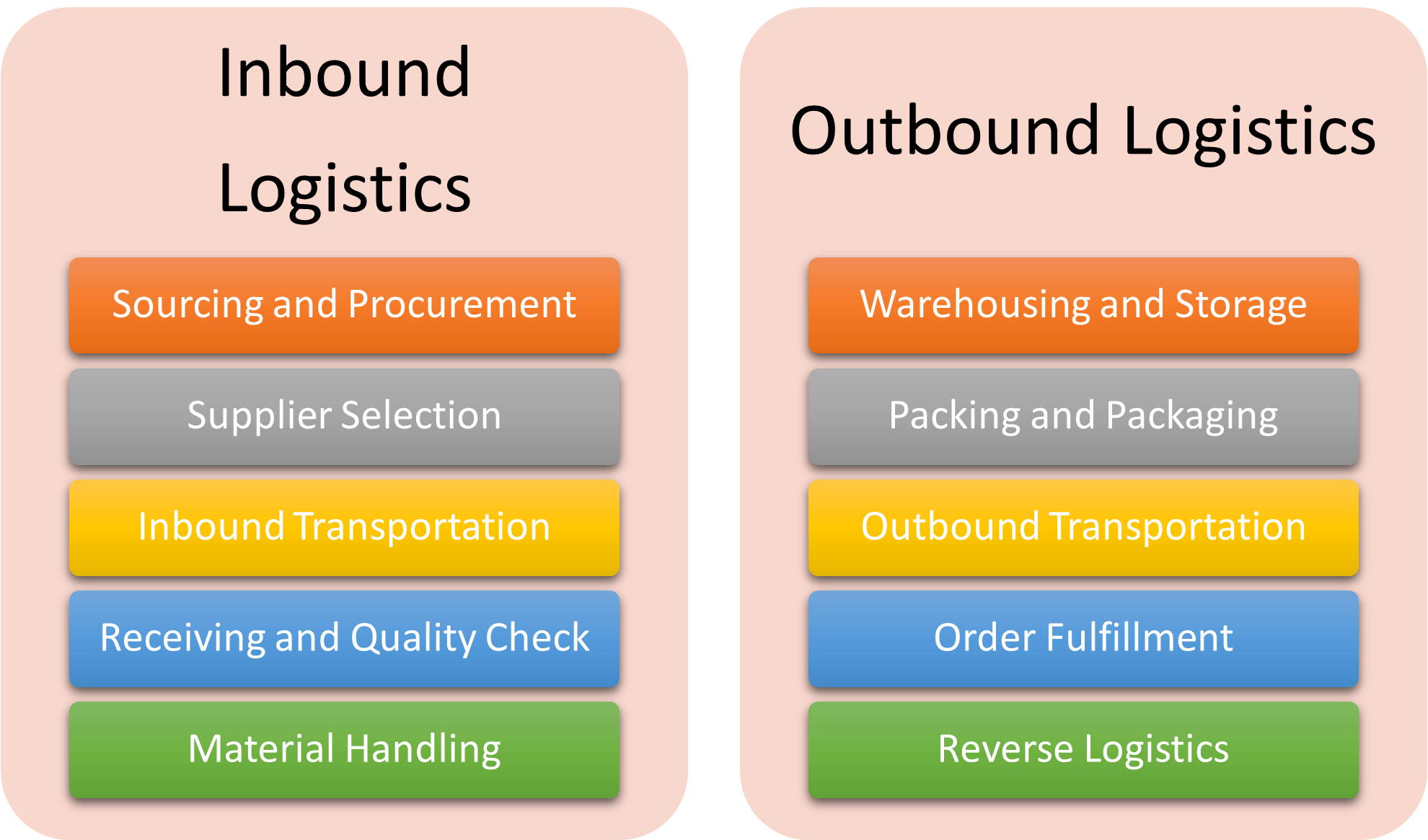

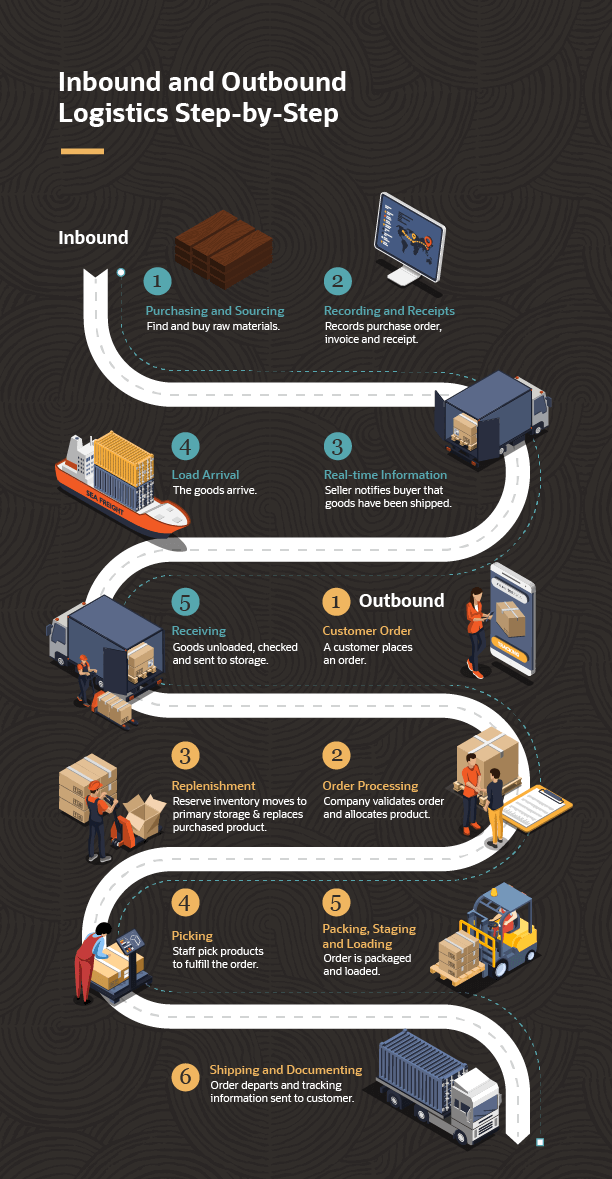

1. Purchasing: This is more than just placing orders. It includes supplier selection, contract negotiation, and ensuring favorable payment terms.

Careful purchasing strategies directly impact the quality and cost of incoming materials.

2. Transportation: This covers the movement of goods from suppliers to your facility.

Choosing the right mode of transport – truck, rail, air, or sea – is crucial for timely and cost-effective delivery.

3. Receiving: This involves unloading incoming shipments, verifying quantities, and inspecting for damage.

Efficient receiving processes are vital for preventing delays and ensuring inventory accuracy.

4. Warehousing and Storage: Proper storage ensures materials are readily available when needed and protected from damage or deterioration.

This includes optimizing warehouse layout and implementing effective storage systems.

5. Inventory Management: Maintaining the right level of inventory is crucial. It balances the risk of stockouts with the cost of holding excess inventory.

Advanced inventory management systems can help optimize stock levels.

6. Materials Handling: This involves the movement of materials within the warehouse or facility.

Efficient materials handling minimizes wasted time and reduces the risk of injury.

7. Supplier Communication: Strong communication with suppliers is essential for coordinating deliveries and resolving any issues that may arise.

This includes sharing forecasts, providing feedback on performance, and working collaboratively to improve the supply chain.

8. Quality Control: Implementing quality control measures throughout the inbound logistics process ensures that incoming materials meet required standards.

This includes inspecting materials upon arrival and working with suppliers to address any quality issues.

The Impact of Efficient Inbound Logistics

Optimizing inbound logistics can lead to significant cost savings, improved efficiency, and enhanced customer satisfaction. It also contributes to a more resilient supply chain.

Companies with strong inbound logistics processes are better positioned to respond to changing market conditions.

According to a recent report by Gartner, companies that invest in advanced inbound logistics technologies, like real-time tracking and predictive analytics, experience a 15% reduction in transportation costs.

McKinsey & Company research suggests that streamlining inbound logistics processes can cut inventory holding costs by up to 20%.

Real-World Examples

Amazon relies heavily on efficient inbound logistics to manage its vast inventory and fulfill orders quickly.

Toyota pioneered the Just-in-Time (JIT) manufacturing system, which requires precise and reliable inbound logistics to deliver materials exactly when they are needed.

These are examples where strategic planning and execution of inbound logistics bring positive change.

The Path Forward

Companies must prioritize inbound logistics to remain competitive in today's global marketplace.

Key steps include investing in technology, streamlining processes, and building strong relationships with suppliers.

Ongoing assessment and adaptation are critical for maintaining an efficient and resilient inbound logistics operation. Monitor performance metrics such as on-time delivery, inventory turnover, and supplier lead times. Companies should also regularly benchmark their performance against industry best practices.

Businesses should also seek feedback from suppliers and internal stakeholders to identify areas for improvement.

The future of inbound logistics involves increased automation, greater use of data analytics, and closer collaboration between all stakeholders in the supply chain. Stay tuned for ongoing developments in this critical area.