Operations And Supply Chain Management The Core

The global economy is a vast, interconnected web, and at its heart lies a critical, often unseen function: operations and supply chain management. Disruptions, whether geopolitical tensions, natural disasters, or unforeseen pandemics, expose vulnerabilities in this intricate network, sending ripples across industries and impacting consumers worldwide. Understanding the core principles of operations and supply chain management is no longer just the domain of business experts; it's essential knowledge for anyone seeking to navigate the complexities of our modern world.

At its core, operations and supply chain management (OSCM) is the design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand and measuring performance globally. This article will delve into the fundamental elements of OSCM, exploring its key components, the challenges it faces, and the innovative strategies being adopted to build more resilient and efficient supply chains for the future. We will examine how companies are adapting to the increasing demands for sustainability, transparency, and responsiveness in a rapidly changing global landscape.

Understanding the Fundamentals

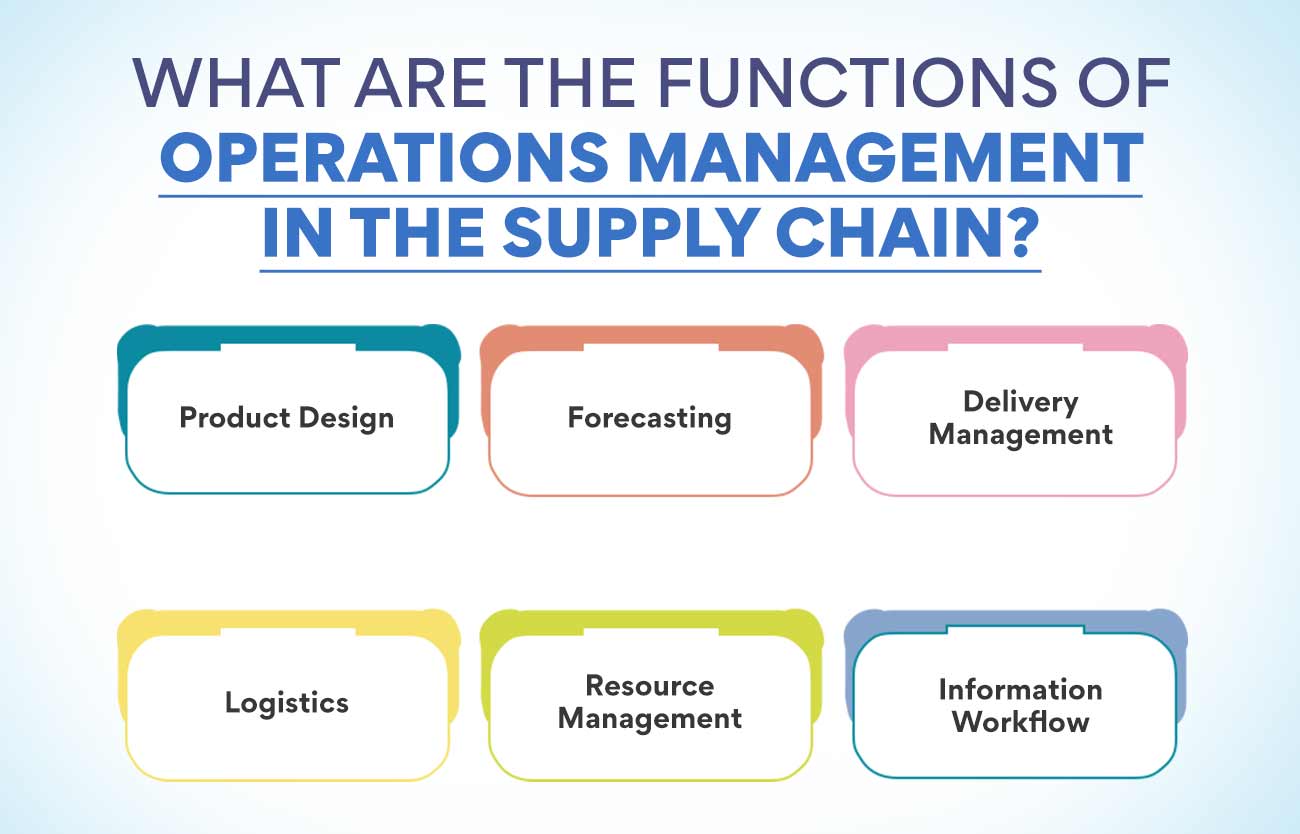

Operations management focuses on the internal processes of an organization, encompassing everything from product design and development to manufacturing and service delivery. It's about optimizing resource utilization, improving efficiency, and ensuring quality throughout the production process. Key areas include process design, capacity planning, inventory management, and quality control.

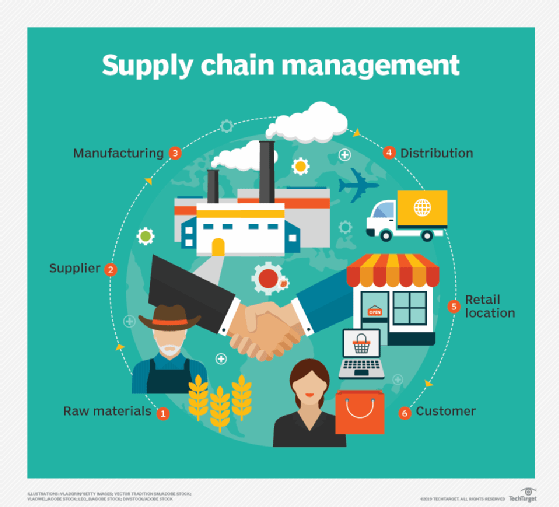

Supply chain management, on the other hand, extends beyond the four walls of the organization. It encompasses the entire network of suppliers, manufacturers, distributors, and retailers involved in bringing a product or service to the end consumer. Effective supply chain management aims to coordinate these entities, optimize the flow of goods and information, and minimize costs while maximizing customer satisfaction.

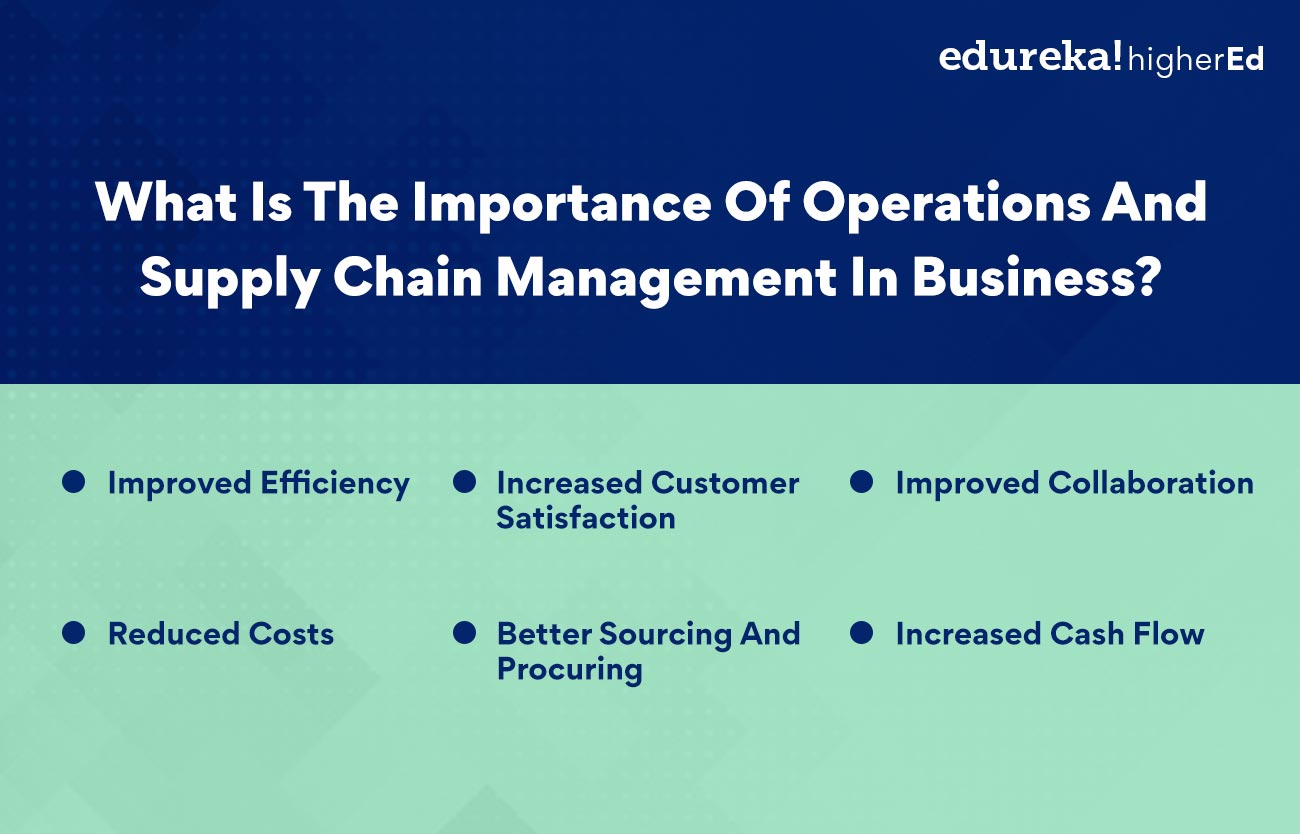

The integration of operations and supply chain management is crucial for achieving a competitive advantage. A well-coordinated OSCM system can reduce lead times, improve responsiveness to customer demand, lower costs, and enhance product quality. According to a report by Deloitte, companies with highly integrated supply chains experience significantly better financial performance than their less integrated counterparts.

Key Components of OSCM

Effective OSCM relies on several key components working in harmony. Forecasting plays a crucial role in predicting future demand, enabling businesses to plan production and inventory levels accordingly. Accurate forecasting minimizes the risk of stockouts or excess inventory, both of which can negatively impact profitability.

Sourcing and Procurement involve selecting suppliers and negotiating contracts to ensure a reliable and cost-effective supply of raw materials and components. Building strong relationships with suppliers is essential for mitigating supply chain disruptions and ensuring quality. Logistics and Transportation are responsible for the efficient movement of goods from suppliers to manufacturers, distributors, and ultimately, to the end consumer.

Inventory Management aims to strike a balance between having enough inventory to meet customer demand and minimizing the costs associated with holding excess inventory. Techniques like Just-in-Time (JIT) inventory management seek to minimize inventory levels by receiving materials only when they are needed for production. Finally, Customer Relationship Management (CRM) plays a vital role in understanding customer needs and preferences, enabling businesses to tailor their supply chain to meet those needs effectively.

The Rise of Technology in OSCM

Technology is transforming OSCM, enabling businesses to optimize processes, improve visibility, and enhance decision-making. Enterprise Resource Planning (ERP) systems integrate various business functions, providing a centralized platform for managing data and coordinating activities across the supply chain. Supply Chain Management (SCM) software provides specialized tools for forecasting, inventory management, and logistics optimization.

Advanced technologies like Artificial Intelligence (AI) and Machine Learning (ML) are being used to automate tasks, predict demand, and optimize supply chain operations. For instance, AI-powered forecasting tools can analyze vast amounts of data to predict demand more accurately than traditional methods. Blockchain technology is enhancing supply chain transparency by providing a secure and immutable record of transactions.

Challenges and Opportunities

Despite the potential benefits, OSCM faces several significant challenges. Global supply chains are inherently complex and vulnerable to disruptions, such as natural disasters, political instability, and economic fluctuations. The COVID-19 pandemic exposed the fragility of global supply chains, leading to widespread shortages and delays.

Another challenge is the increasing demand for sustainability and ethical sourcing. Consumers are becoming more aware of the environmental and social impact of products, and they expect companies to operate responsibly. This requires businesses to track their supply chains, ensure compliance with environmental regulations, and promote fair labor practices.

However, these challenges also present opportunities for innovation and improvement. Companies are investing in supply chain resilience, diversifying their supplier base, and building redundant capacity to mitigate the impact of disruptions. They are also adopting sustainable practices, such as reducing waste, using renewable energy, and promoting circular economy principles. Furthermore, the implementation of digital twins, virtual representations of the supply chain, allows companies to simulate scenarios and proactively manage risks.

The Future of OSCM

The future of OSCM will be characterized by greater resilience, sustainability, and technological integration. Companies will need to build more agile and adaptable supply chains that can respond quickly to changing market conditions and disruptions. Sustainability will become an increasingly important consideration, driving innovation in product design, manufacturing processes, and logistics.

The rise of e-commerce and the increasing demand for personalized products will require businesses to develop more flexible and responsive supply chains. 3D printing and other advanced manufacturing technologies will enable companies to produce goods closer to the point of consumption, reducing lead times and transportation costs.

Ultimately, effective OSCM will be a key differentiator for businesses in the future. Companies that can master the complexities of supply chain management, embrace technology, and prioritize sustainability will be best positioned to succeed in the global marketplace. The ability to orchestrate a seamless, efficient, and responsible supply chain will be the cornerstone of competitive advantage in the years to come.