Repairing Composite Materials Using Glue Injection

Urgent action is underway following a breakthrough in composite material repair. A novel glue injection technique promises to drastically reduce downtime and costs across industries relying on lightweight, high-strength structures.

This method, rapidly gaining traction, allows for on-site repairs of damaged composite components, circumventing costly replacements and lengthy factory visits.

The Glue Injection Revolution

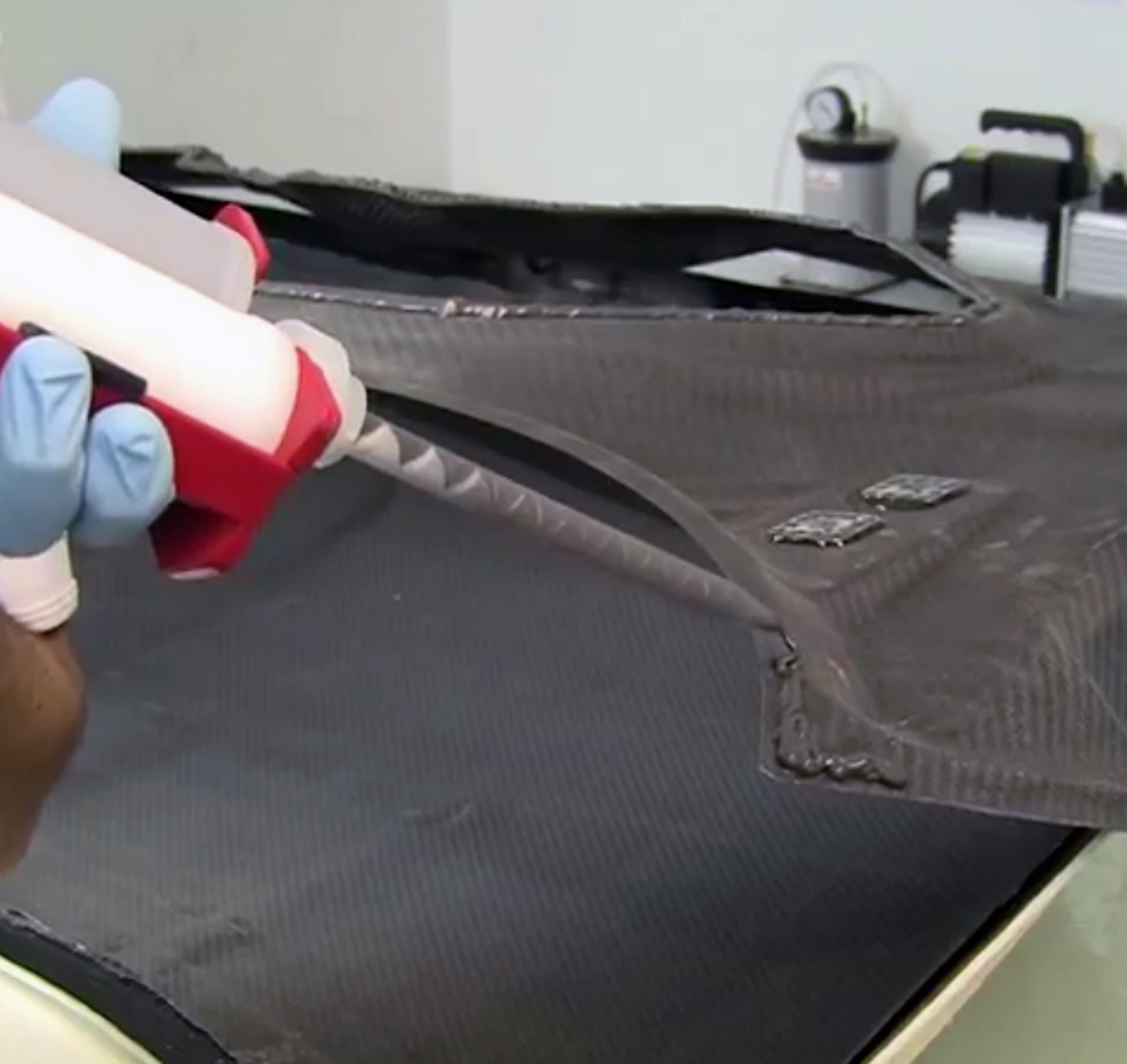

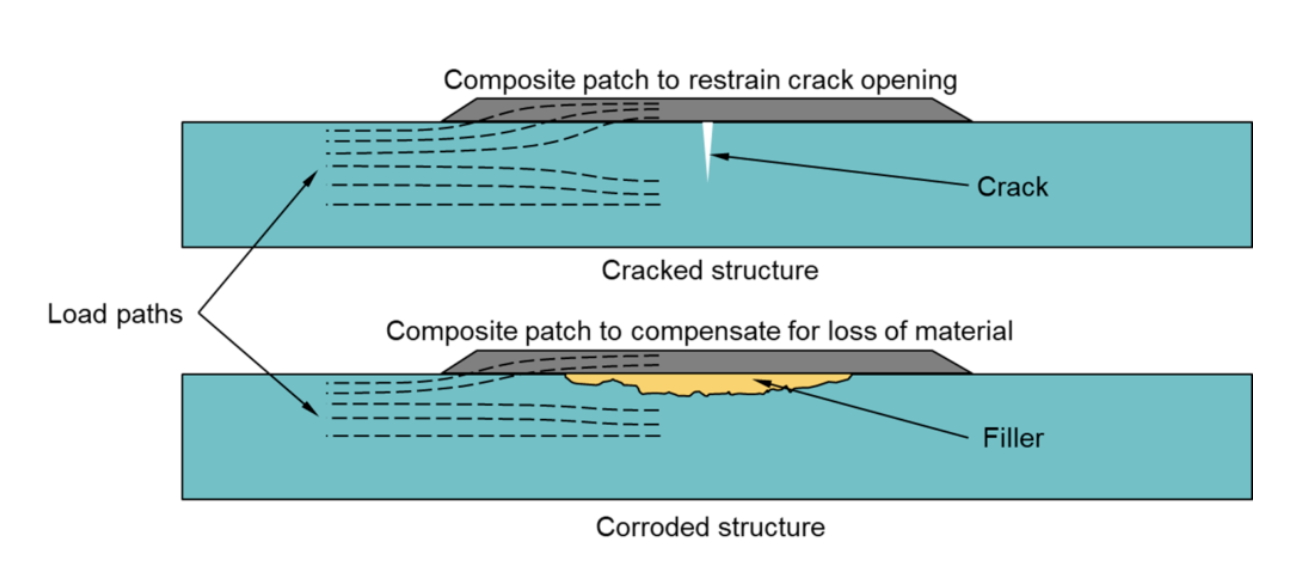

The Glue Injection Repair (GIR) process involves injecting a specialized adhesive into delaminations or cracks within composite materials. This fills the voids, rebonding the layers and restoring structural integrity.

Dr. Anya Sharma, lead researcher at the Advanced Composites Research Institute (ACRI), spearheaded the development. The ACRI confirmed the technique's efficacy in a press release earlier today.

How it Works

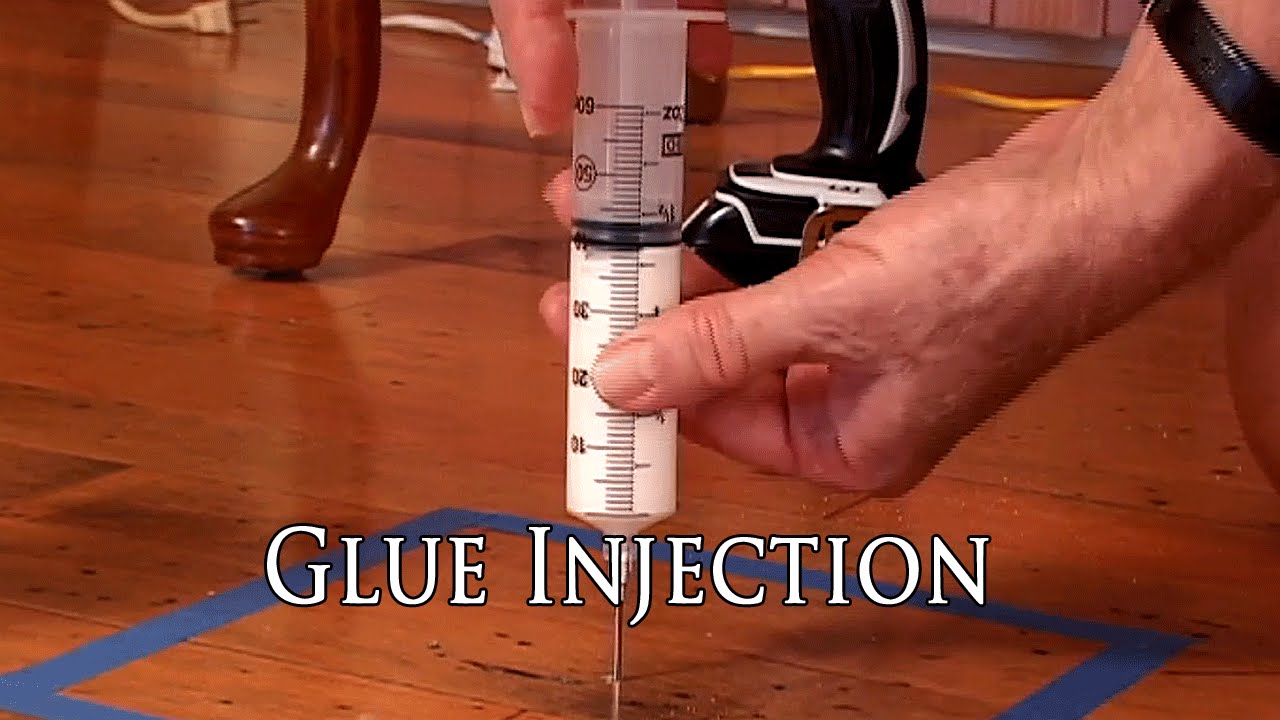

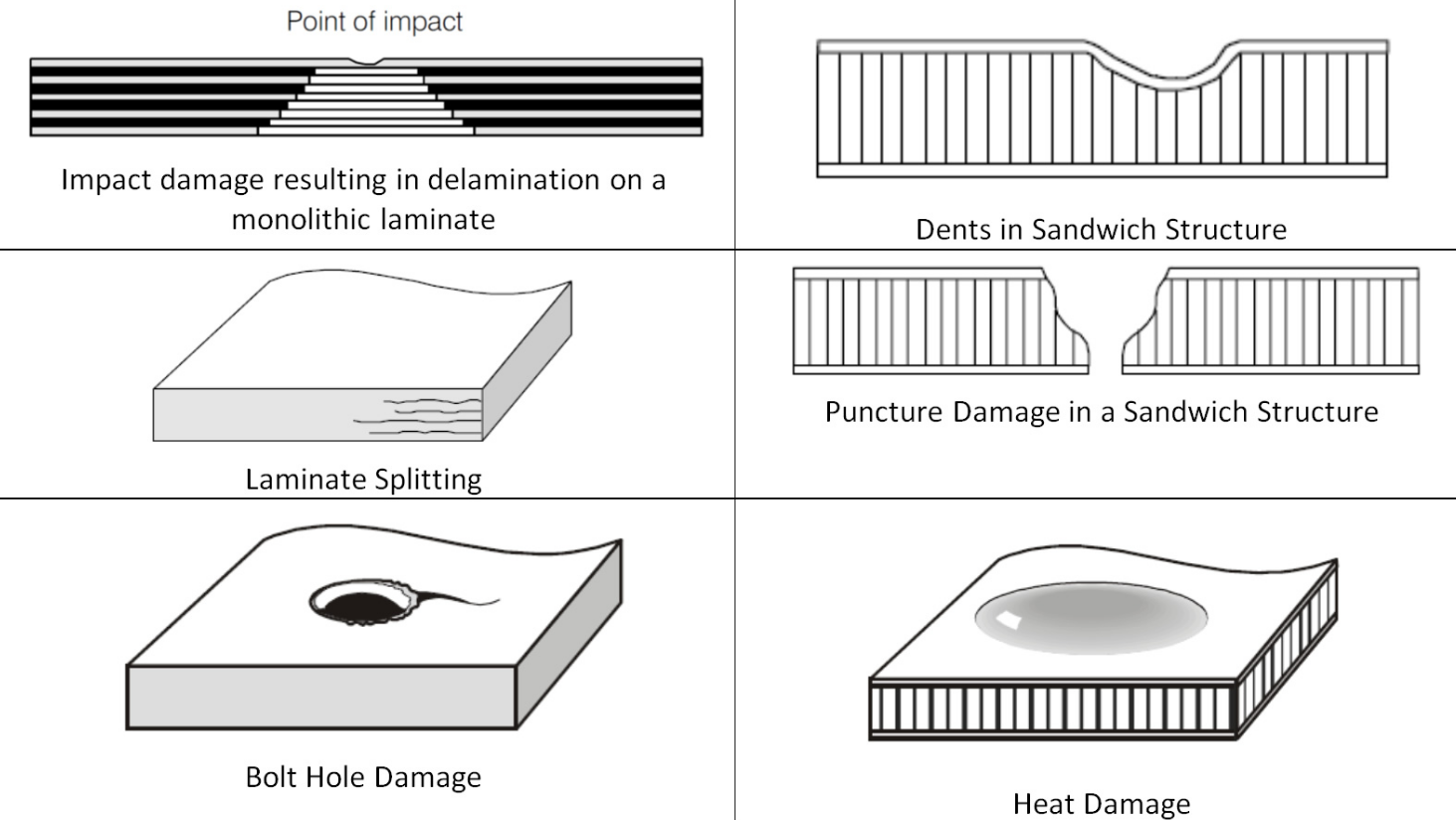

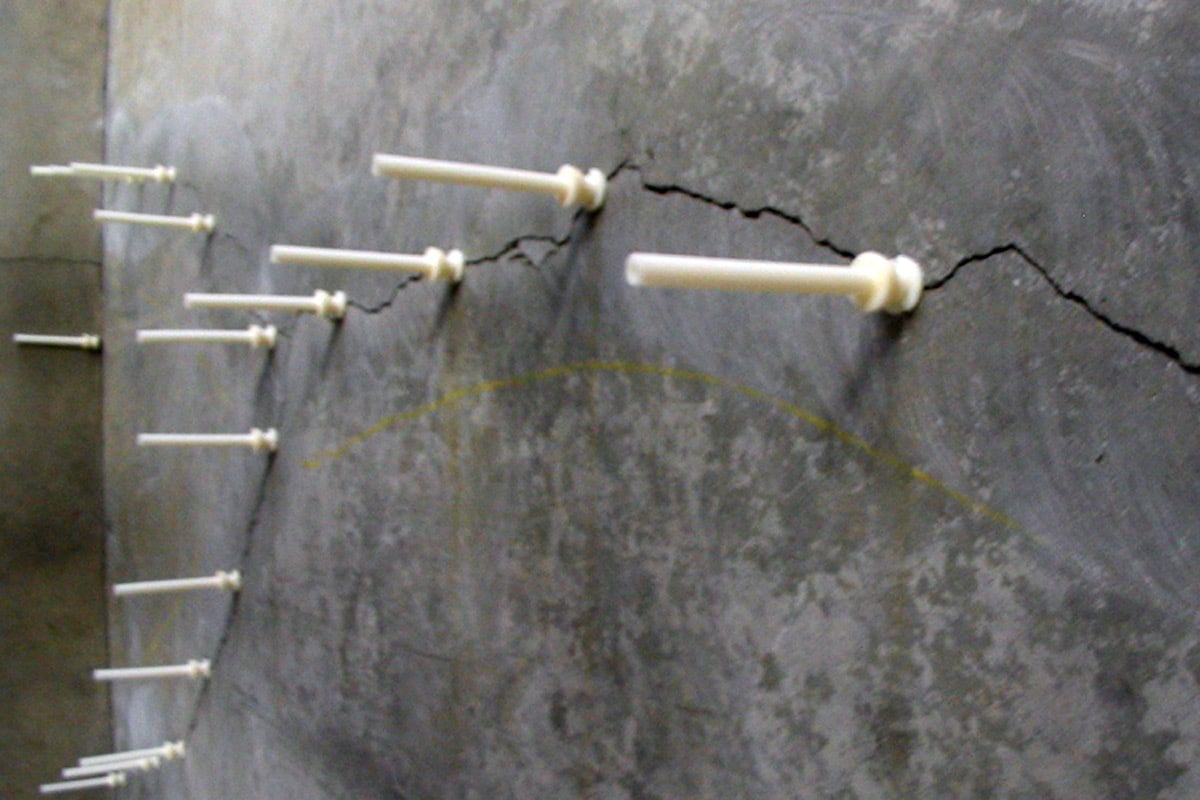

The GIR process begins with a thorough inspection of the damaged area using non-destructive testing (NDT) methods. This identifies the extent and location of the damage.

Next, small access points are carefully drilled into the composite structure. The specialized adhesive, formulated for high bonding strength and compatibility, is then injected under controlled pressure.

Finally, the injected adhesive is cured, typically using heat or ultraviolet (UV) light, to achieve optimal bonding. The access points are then sealed, and the repaired area is refinished.

Who Benefits?

The aerospace, automotive, and marine industries stand to benefit most significantly from GIR. These sectors heavily rely on composite materials for their strength-to-weight ratio.

Boeing and Airbus are reportedly evaluating GIR for potential applications in aircraft maintenance. Several automotive manufacturers are also exploring its use in repairing carbon fiber components.

The marine industry is seeing particularly interest, especially for repairing large composite boat hulls. Traditional repair methods often require dry-docking, a time-consuming and expensive process.

When and Where?

The GIR technique has been under development at ACRI for the past five years. Initial field trials began in late 2023 at a wind turbine farm in Denmark, yielding promising results.

ACRI anticipates widespread adoption of GIR within the next 12-18 months. Several companies are already licensed to offer the repair service.

Pilot programs are currently underway at select maintenance facilities in the United States, Europe, and Asia.

Essential Details

The adhesive used in GIR is a proprietary formulation developed by ACRI. Its specific composition remains confidential for now.

However, ACRI confirms it is a two-part epoxy resin with enhanced adhesion and impact resistance. The curing process typically takes between 2 and 24 hours, depending on the adhesive type and environmental conditions.

Independent testing has shown that GIR can restore up to 90% of the original strength of the composite material. In some cases, it can even exceed the original strength.

Impact and Challenges

The adoption of GIR could lead to significant cost savings for industries that rely on composite materials. Reduced downtime and avoidance of costly replacements are key drivers.

However, challenges remain, including the need for skilled technicians to perform the repairs. Proper training and certification are essential to ensure the quality and reliability of the repairs.

Ensuring long-term durability and monitoring repaired areas for potential future damage are also crucial considerations.

Ongoing Developments

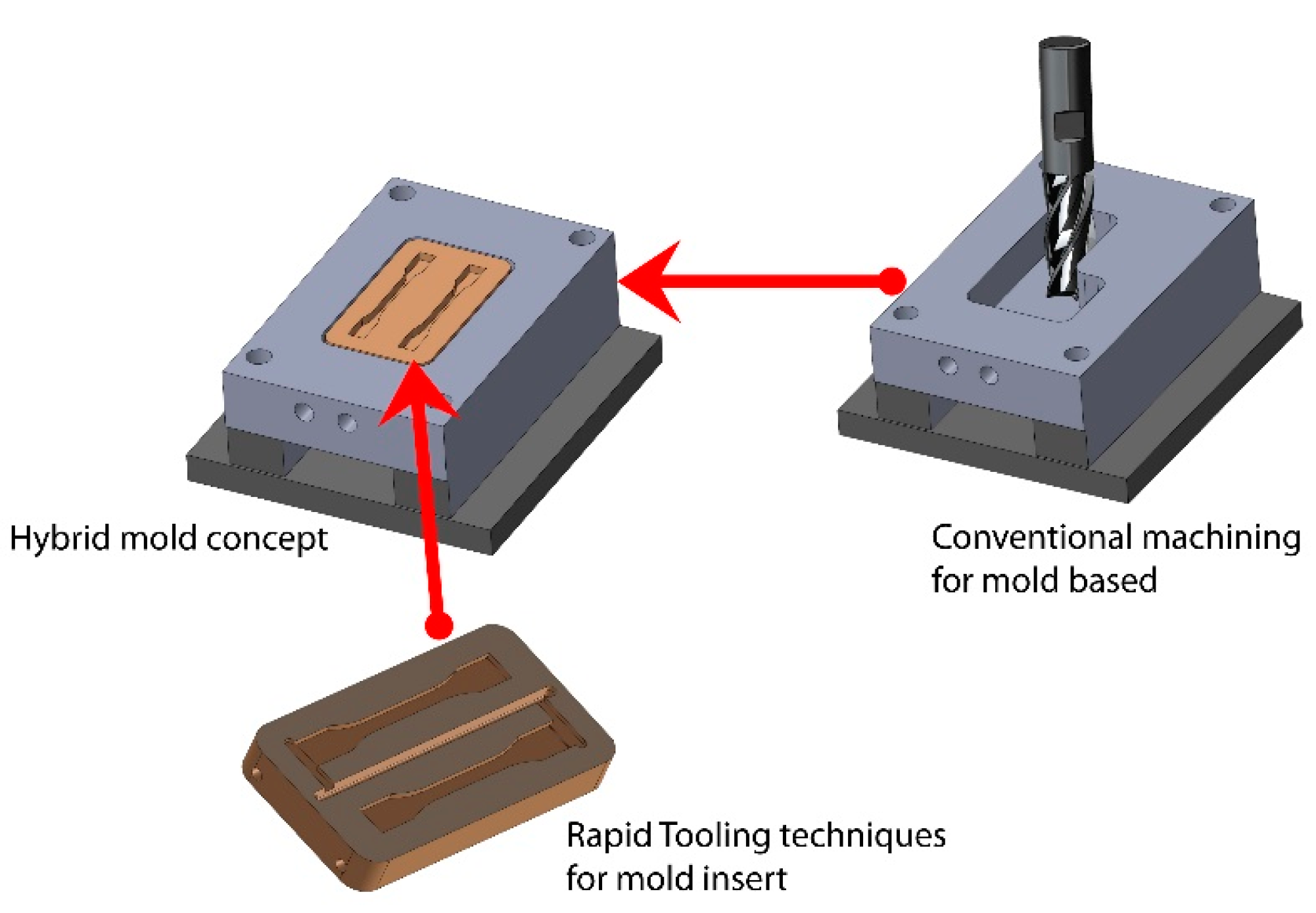

ACRI is actively working on further refining the GIR technique. This includes developing new adhesives with improved properties and exploring automated injection systems.

Researchers are also investigating the use of GIR for repairing a wider range of composite materials. This includes thermosets and thermoplastics.

ACRI will host a workshop on GIR in November to train technicians and disseminate best practices. Registration is now open.

Dr. Sharma stated, "We believe GIR has the potential to revolutionize composite material repair. Our goal is to make it accessible and reliable for industries worldwide."