Traditional Transactional Based Logistics Focuses On

For decades, the logistics industry has largely operated on a transactional basis, prioritizing individual shipments and cost optimization for each specific transaction. This traditional model, while efficient in certain aspects, is now facing increasing scrutiny as businesses seek more integrated, resilient, and customer-centric supply chains.

The shift away from this purely transactional approach signifies a fundamental change in how companies view logistics – moving from a series of isolated events to a continuous, interconnected process that requires greater collaboration and a long-term strategic vision. This article examines the limitations of traditional transactional logistics and explores the emerging trends driving the adoption of more holistic and relationship-based strategies.

The Drawbacks of Transactional Logistics

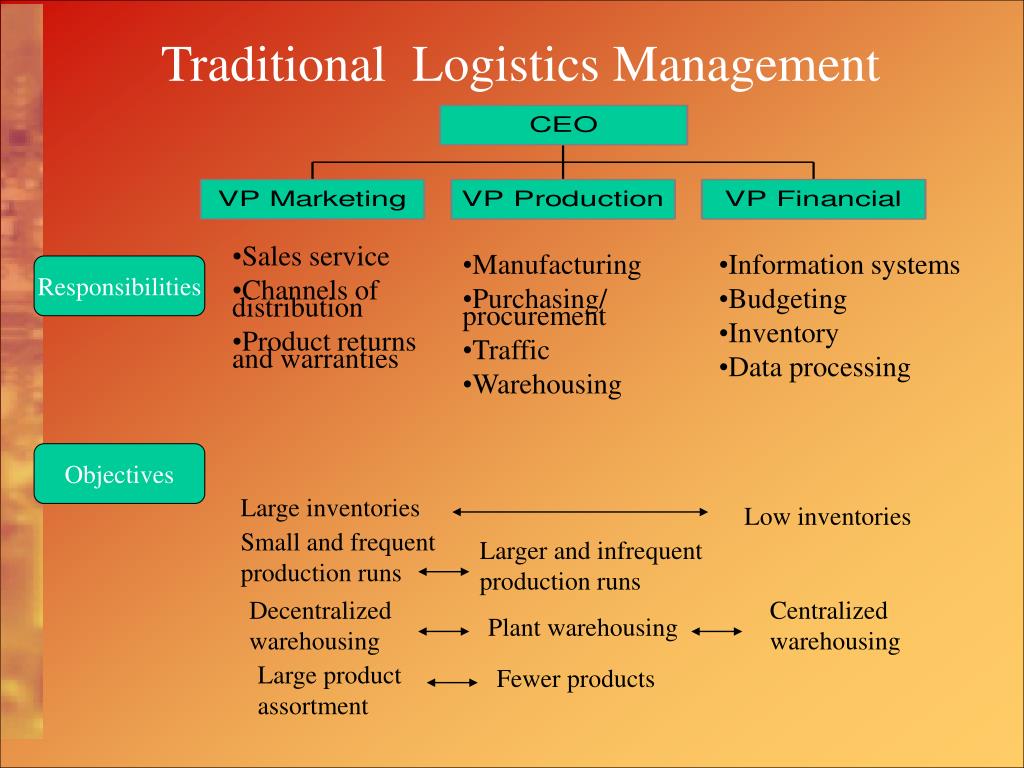

Traditional transactional logistics focuses primarily on optimizing cost and efficiency for each individual transaction, such as a single shipment or a specific delivery route. Cost minimization is often the primary driver, leading companies to select the cheapest available option for each transaction without necessarily considering the long-term implications or potential risks.

This approach often results in a fragmented supply chain, characterized by a lack of visibility and coordination between different players. Communication tends to be limited, with each party focusing on their specific role without a comprehensive understanding of the overall process.

This lack of integration can lead to several significant problems. For example, delays or disruptions in one part of the supply chain can have a cascading effect, impacting the entire system. Inventory management becomes more challenging, leading to higher holding costs and potential stockouts.

Furthermore, transactional logistics often fails to prioritize customer satisfaction. The focus is primarily on completing the transaction at the lowest possible cost, without necessarily considering the customer's specific needs or preferences.

The Rise of Relationship-Based Logistics

In response to the limitations of transactional logistics, businesses are increasingly adopting a more relationship-based approach. This involves building long-term partnerships with logistics providers, fostering greater collaboration and information sharing.

These partnerships enable companies to achieve greater supply chain visibility, allowing them to track shipments in real-time and proactively identify potential disruptions. Improved communication and coordination facilitate faster decision-making and more effective problem-solving.

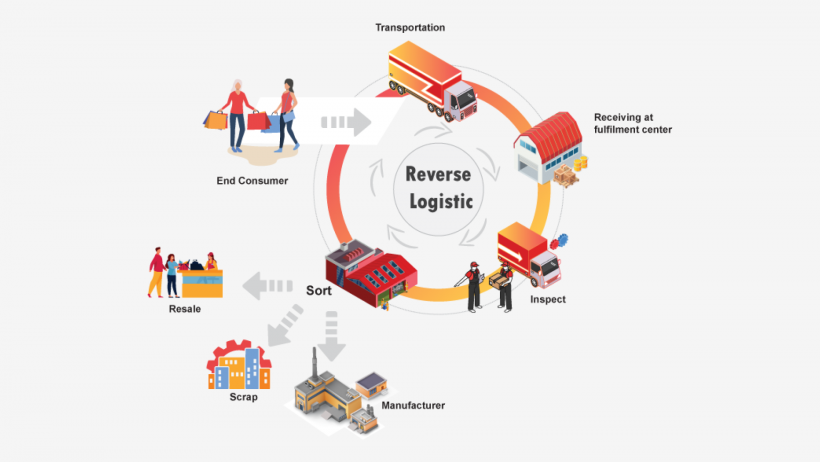

Relationship-based logistics also allows for greater customization. Logistics providers can tailor their services to meet the specific needs of their clients, offering value-added services such as specialized packaging, reverse logistics, and last-mile delivery solutions.

Technology as an Enabler

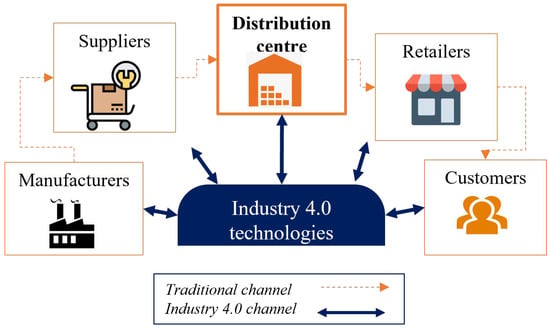

Technology plays a crucial role in facilitating the shift towards relationship-based logistics. Cloud-based platforms and data analytics tools enable real-time visibility and collaboration across the entire supply chain.

These technologies allow companies to gather and analyze data from various sources, gaining valuable insights into their supply chain performance. This data can then be used to identify areas for improvement, optimize processes, and make more informed decisions.

Blockchain technology is also emerging as a potential game-changer in the logistics industry. By providing a secure and transparent ledger of transactions, blockchain can help to build trust and collaboration between different players in the supply chain.

The Impact on Businesses and Consumers

The move away from traditional transactional logistics has significant implications for both businesses and consumers. For businesses, it can lead to reduced costs, improved efficiency, and increased resilience.

By building stronger relationships with their logistics providers, companies can negotiate better rates, improve service levels, and gain access to a wider range of value-added services. This can help them to gain a competitive advantage in the marketplace.

For consumers, the benefits of relationship-based logistics include faster delivery times, improved order accuracy, and greater transparency. They can track their shipments in real-time and receive proactive updates on any potential delays or disruptions.

Ultimately, the shift towards relationship-based logistics is about creating a more customer-centric supply chain. By focusing on building strong relationships and leveraging technology, companies can deliver a better experience for their customers and build long-term loyalty.

A Real-World Example

Consider a hypothetical scenario: a small business selling handcrafted goods online. Under a transactional logistics model, the business might choose the cheapest shipping option for each order, potentially leading to inconsistent delivery times and damaged goods.

However, by partnering with a logistics provider that offers customized solutions and proactive communication, the business can ensure a more reliable and positive customer experience. This might involve using specialized packaging to protect delicate items, offering expedited shipping options, and providing real-time tracking updates.

This investment in a stronger logistics partnership can lead to increased customer satisfaction, repeat business, and positive word-of-mouth referrals, ultimately driving long-term growth for the small business.

Conclusion

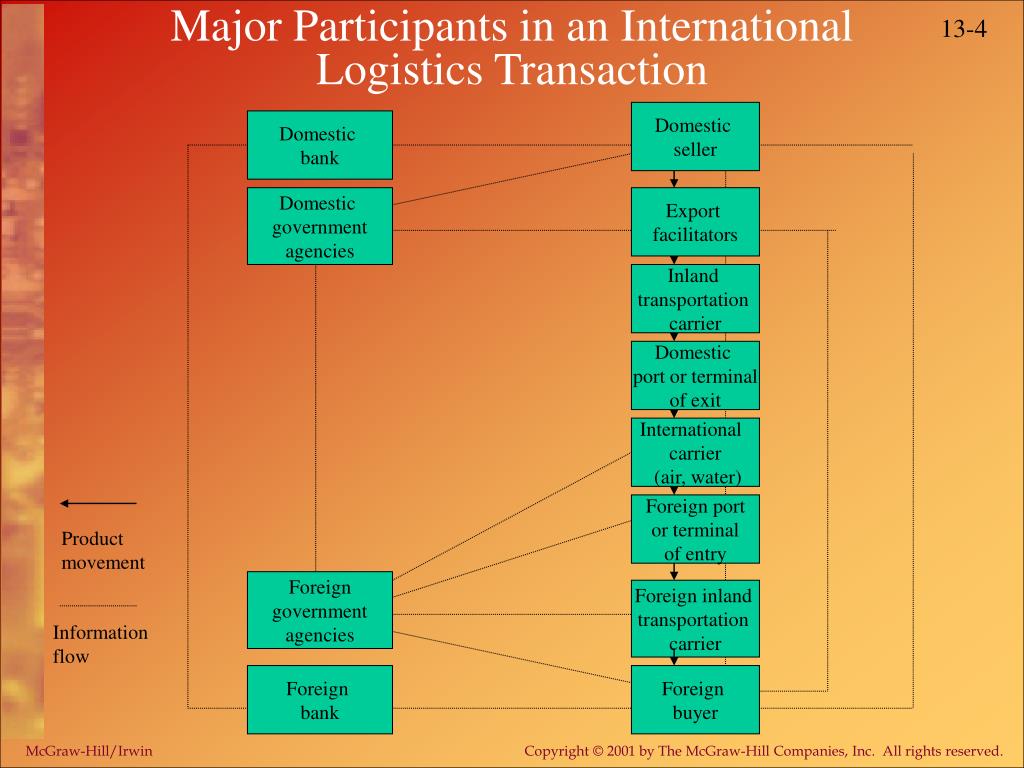

The days of solely focusing on transactional logistics are numbered. The increasing complexity and volatility of the global supply chain demand a more holistic and collaborative approach.

Businesses that embrace relationship-based logistics and invest in technology to improve visibility and communication will be best positioned to thrive in the years to come. The future of logistics lies in building strong partnerships, fostering greater collaboration, and prioritizing customer satisfaction.

The transition represents not just an evolution in operational practices, but a fundamental shift in strategic thinking, positioning logistics as a key driver of competitive advantage rather than merely a cost center.