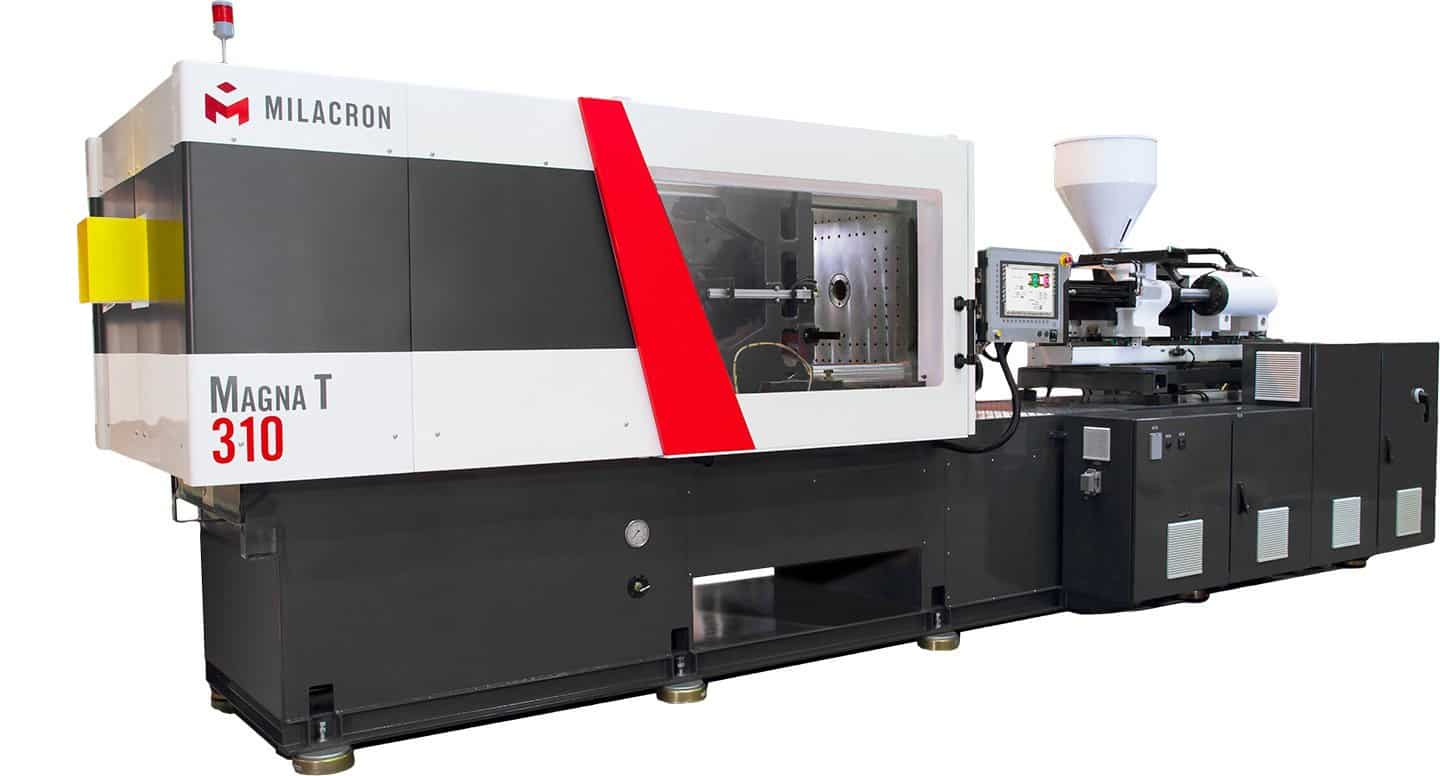

Milacron Injection Molding Machine Price

Breaking: Prices for Milacron injection molding machines are surging, effective immediately, impacting manufacturers globally. This sudden shift necessitates immediate action for companies planning capital investments or expansions.

The price increase, announced this morning, affects all new Milacron machine orders. The hike stems from escalating raw material costs, supply chain disruptions, and increased demand, sending ripples through the manufacturing sector.

Immediate Price Surge Details

The price adjustment averages a 7-12% increase across Milacron's entire injection molding machine portfolio. Specific models and customization options may experience even higher price adjustments. These new prices are now in effect for all new orders placed after the announcement.

Factors Driving the Increase

Raw material costs, particularly steel and polymers, have spiked significantly in recent months. These increases directly impact the manufacturing cost of Milacron's machines. Global supply chain bottlenecks continue to exacerbate the problem, delaying component deliveries and raising transportation expenses.

Simultaneously, demand for injection molding machinery is experiencing a surge. This increase is driven by reshoring initiatives and overall growth in manufacturing sectors such as automotive and packaging.

Impact on Manufacturers

Manufacturers reliant on injection molding will face immediate cost implications. Companies operating with tight margins may need to reassess their capital expenditure budgets. This price hike could potentially delay or scale down planned expansions or equipment upgrades.

Small and medium-sized enterprises (SMEs) are expected to be particularly vulnerable to this sudden change. They may lack the negotiating power of larger corporations to mitigate the increased costs. Alternate suppliers or used equipment options may become more attractive alternatives.

“This price adjustment reflects the unprecedented challenges we face in maintaining consistent supply and managing escalating costs,” said a Milacron spokesperson.

Regional Variations

The impact of the price increase will vary slightly by region. Regions heavily reliant on imported steel or experiencing severe supply chain congestion will likely feel the effects more acutely. Currency fluctuations could further amplify or dampen the impact depending on the manufacturer's location.

North American manufacturers may experience a more significant impact. European markets, while also affected, may have existing contracts that provide some temporary buffer. Asian manufacturers will need to carefully assess the impact of both material costs and currency exchange rates.

Strategic Responses

Manufacturers are advised to immediately review their existing procurement strategies. Exploring alternative materials or component sourcing could help offset the rising costs. Engaging in early negotiations with Milacron and exploring financing options are also critical.

Companies should consider optimizing their production processes to improve efficiency and reduce waste. This can help minimize the overall impact of the increased machine prices. Investing in automation and advanced control systems can provide long-term cost savings.

Looking Ahead

Milacron has stated that it will continue to monitor the market conditions closely. Further price adjustments may be necessary if the underlying cost pressures persist. The company is actively working to mitigate supply chain disruptions and explore alternative sourcing options.

Manufacturers should stay informed about market trends and economic indicators. This will allow them to anticipate future price fluctuations and adjust their business strategies accordingly. Close collaboration with industry associations and suppliers is essential.

The situation is fluid, and further updates are expected. Stay tuned for continuing coverage and analysis of this developing story.