Low Temperature Synthesis Using Molten Salt

The quest for sustainable and efficient material synthesis is intensifying as global demand for advanced technologies soars. Traditional high-temperature methods, often energy-intensive and environmentally unfriendly, are increasingly scrutinized. A promising alternative, molten salt synthesis, is gaining momentum as a low-temperature route to producing a wide array of materials with tailored properties.

Molten salt synthesis offers a compelling pathway to create advanced materials at significantly lower temperatures compared to conventional methods. This technique utilizes molten salts as reaction media, allowing for precise control over particle size, morphology, and crystallinity. It has the potential to revolutionize various sectors, from battery technology and catalysis to ceramics and electronics.

The Principles of Molten Salt Synthesis

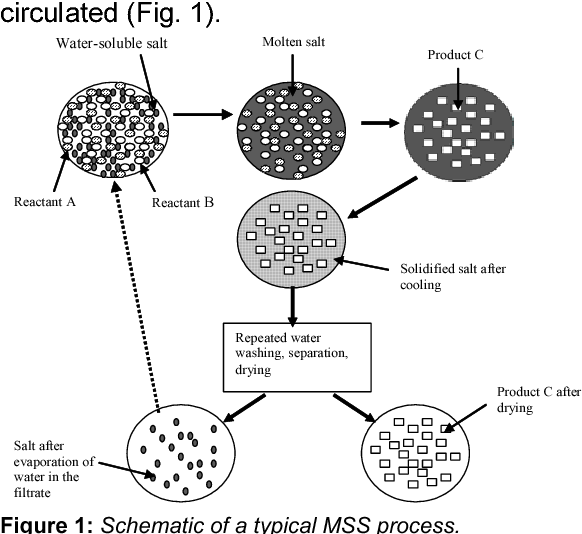

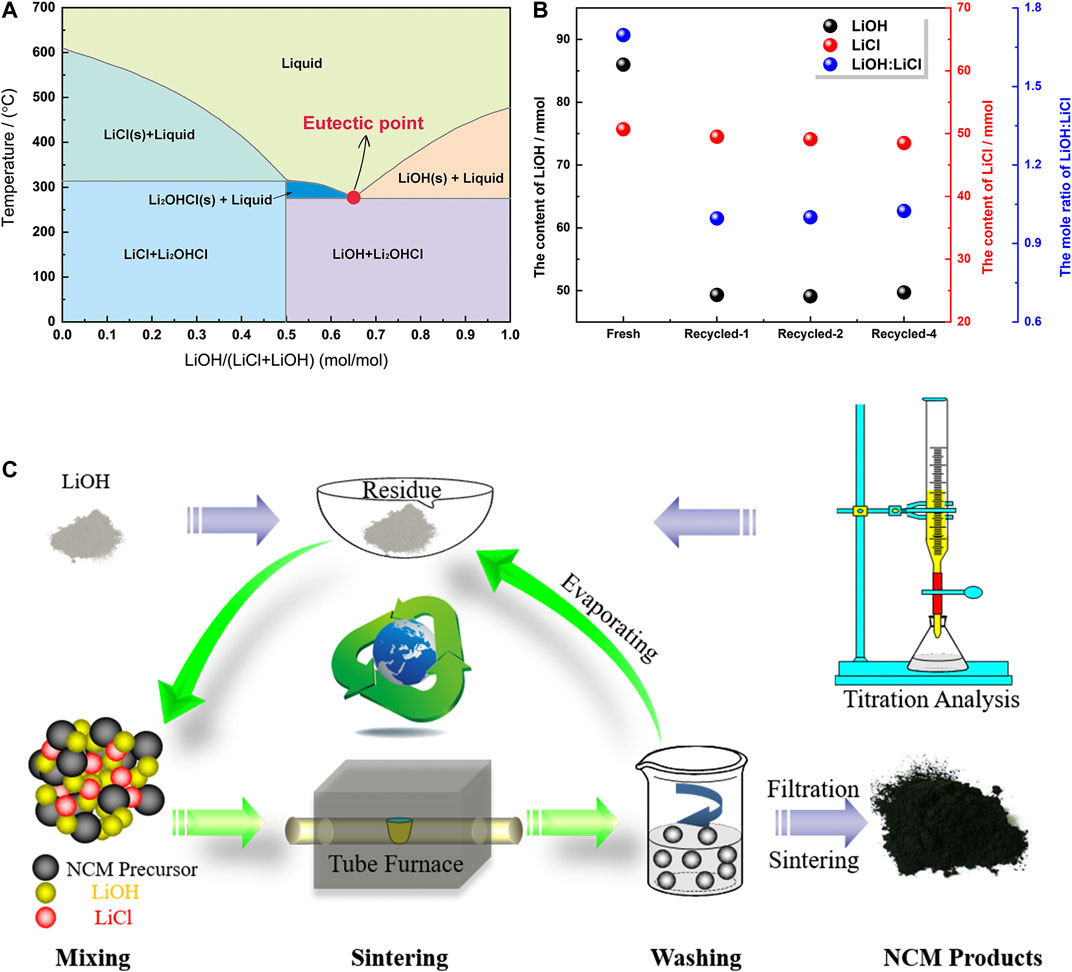

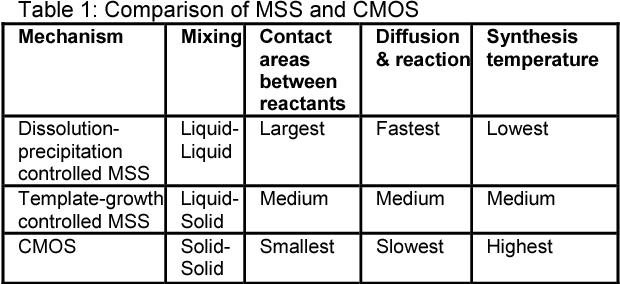

At its core, molten salt synthesis leverages the unique properties of molten salts, which are ionic compounds in a liquid state at elevated temperatures. These salts act as solvents and reaction media, facilitating the dissolution and interaction of precursor materials. The low viscosity and high ion mobility of molten salts promote rapid diffusion and reaction kinetics.

This leads to lower reaction temperatures, typically ranging from 200°C to 800°C, compared to solid-state reactions that often require temperatures exceeding 1000°C. By carefully selecting the appropriate salt composition, temperature, and reaction time, researchers can precisely control the material's properties.

Advantages Over Traditional Methods

One of the primary advantages of molten salt synthesis is its energy efficiency. The lower reaction temperatures translate to reduced energy consumption and lower carbon footprint, aligning with growing sustainability concerns. Furthermore, the technique often yields materials with superior purity and homogeneity compared to traditional methods.

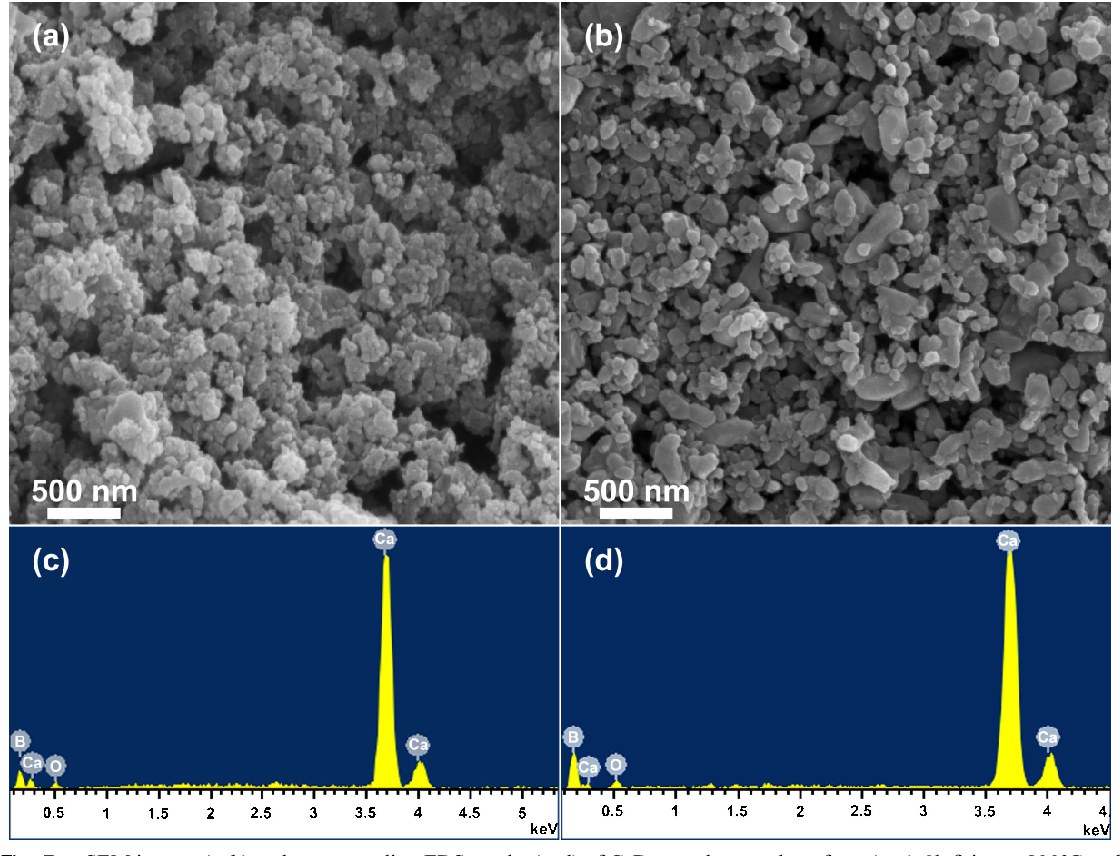

The liquid environment also facilitates the formation of nanocrystals and other nanostructured materials with well-defined morphologies. This precise control over particle size and shape is crucial for optimizing material performance in various applications. Moreover, molten salt synthesis can be used to create metastable phases and novel compositions that are inaccessible through conventional methods.

Applications Across Industries

The versatility of molten salt synthesis has led to its exploration across a diverse range of industries. In battery technology, it is used to synthesize cathode materials, such as lithium iron phosphate (LiFePO4) and lithium manganese oxide (LiMn2O4), with enhanced electrochemical performance.

These materials exhibit improved ion conductivity and cycle life, contributing to the development of high-performance batteries for electric vehicles and energy storage systems. In the field of catalysis, molten salt synthesis enables the creation of catalysts with high surface areas and uniform pore structures. These catalysts exhibit enhanced activity and selectivity in various chemical reactions, promoting efficient and sustainable chemical processes.

Moreover, the technique is used to produce advanced ceramics with improved mechanical properties and thermal stability. These ceramics find applications in high-temperature coatings, structural components, and electronic devices. In the electronics sector, molten salt synthesis is employed to create thin films and nanostructures for transistors, solar cells, and other electronic components.

Challenges and Opportunities

Despite its numerous advantages, molten salt synthesis also faces certain challenges. The corrosive nature of some molten salts can pose difficulties in terms of reactor design and material selection. The removal of residual salts from the synthesized materials can also be a complex and time-consuming process.

Furthermore, the optimization of reaction parameters, such as salt composition, temperature, and reaction time, requires careful consideration and experimentation. However, ongoing research efforts are focused on addressing these challenges and expanding the applicability of molten salt synthesis. Researchers at the Oak Ridge National Laboratory (ORNL) are actively exploring novel salt compositions and developing new reactor designs to overcome these limitations.

According to a recent report by Market Research Future, the global molten salt synthesis market is expected to witness significant growth in the coming years. This growth is driven by the increasing demand for high-performance materials and the growing adoption of sustainable manufacturing practices. The development of more environmentally friendly and cost-effective molten salts will further accelerate the adoption of this technology.

The Future of Material Synthesis

Molten salt synthesis represents a paradigm shift in material synthesis, offering a sustainable and efficient alternative to traditional high-temperature methods. As research and development efforts continue to advance, this technique is poised to play an increasingly important role in various industries. The potential for creating novel materials with tailored properties will drive innovation and lead to the development of advanced technologies.

The collaboration between academia, industry, and government laboratories is crucial for accelerating the commercialization of molten salt synthesis. By addressing the remaining challenges and exploring new applications, this technology can pave the way for a more sustainable and technologically advanced future.

"Molten salt synthesis provides a unique opportunity to create materials with unprecedented control over their properties,"says Dr. Emily Carter, a leading materials scientist at Princeton University. "It is a powerful tool for designing materials for a wide range of applications."